Coenzyme Q10 drug delivery system and preparation method thereof

A drug delivery system and coenzyme technology, which can be used in drug combinations, pharmaceutical formulations, cardiovascular system diseases, etc., can solve problems such as instability, low drug loading, and emulsifier toxicity, reduce loss rate, improve solubility, The effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

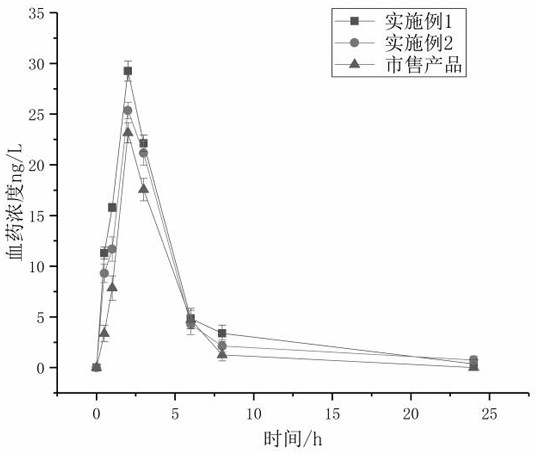

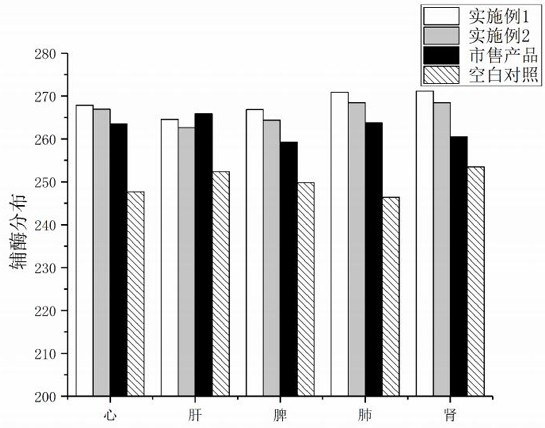

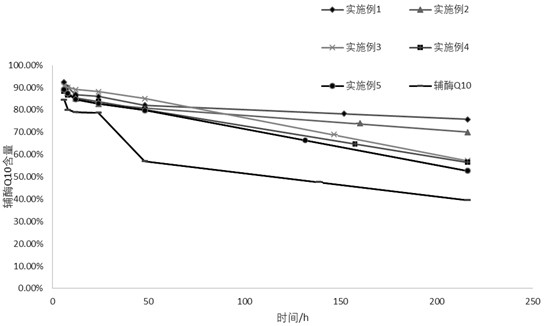

Embodiment 1

[0028] Add 2g of coenzyme Q10, 32g of protamine, 0.055g of micropowdered silica gel, 0.35g of 2,6-di-tert-butyl-4-methylphenol (BHT), 4.45g of poloxamer into a 500 mL stainless steel ball mill jar, 64 stainless steel ball milling beads with a diameter of 15 mm were ground for reaction at 200 rpm for 4 hours. After the reaction, the drug was separated from the stainless steel ball milling beads to obtain a coenzyme Q10 drug delivery system.

Embodiment 2

[0030] Add 1g of coenzyme Q10, 30g of soybean protein, 0.05g of talcum powder, 0.35g of DL tocopherol, 4.55g of monoglyceride and diglyceride stearate, and 64 stainless steel ball milling beads with a diameter of 15mm into a 500 mL stainless steel ball mill jar, at 200rpm The reaction was ground for 4 hours, and the drug was separated from the stainless steel ball milling beads after the reaction to obtain a coenzyme Q10 drug delivery system.

Embodiment 3

[0032] Add 6g of coenzyme Q10, 25g of casein and hemoglobin, 0.05g of tricalcium phosphate, 0.45g of vitamin palmitate, 4.45g of disodium glycyrrhizinate and sodium caseinate into a 500 mL stainless steel ball mill jar, and stainless steel ball milling beads with a diameter of 25mm 64 were ground for 4 hours at 100rpm. After the reaction, the drug was separated from the stainless steel ball milling beads to obtain a coenzyme Q10 drug delivery system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com