Self-cleaning glass with strong adhesive force, and preparation method thereof

A technology of strong adhesion and adhesion silane, applied in chemical instruments and methods, glass/slag layered products, lamination devices, etc., can solve the problem of affecting the sterilization and anti-fog effect of clean glass, loss of self-cleaning effect, and energy utilization Limitations and other issues, to achieve the effect of improving visible light transmittance, photocatalytic efficiency, and catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

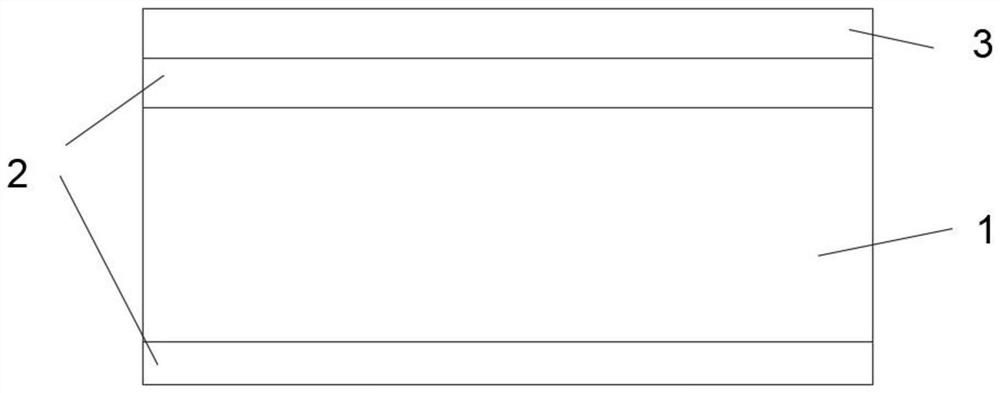

[0030]Seefigure 1The present invention provides a technical solution: a self-cleaning glass with strong adhesion and a preparation method thereof, including in order to solve the above technical problems, the present invention provides the following technical solution: a self-cleaning glass with strong adhesion and a preparation method thereof, including The glass base layer 1 is characterized in that: the glass base layer 1 is attached with a strong adhesion bonding layer 2, at least one side of the bonding layer 2 is provided with a self-cleaning nanomaterial layer 3, and the glass base layer 1 has a thickness of 3-12mm The thickness of conventional architectural glass can be used as a glass substrate, the thickness of the bonding layer 2 is 4-8 μm, and the thickness of the self-cleaning nano-layer 3 is 3-6 μm.

[0031]According to the above technical solution, the following steps: Wash the glass matrix 1 as a substrate, because the cache of the substrate has a great influence on the...

Embodiment 1

[0044]Wash the glass matrix, the cleaning step is to clean the glass sheet in the order of deionized water, acetone, anhydrous ethanol and deionized water, and then cleaned 10-15 min, then put the cleaning slide after cleaning In the drying box, dried at 100 ° C to be used.

[0045]Silicon group R '(CH2NSI (OR)3The aqueous solution was added to the chromium hydroxide control GROH molar ratio of 4: 1. Alkyl hydrolysis release SiOH groups with hydroxide for shrinking: SiOH + GROH = SiOGR + H2O, stir for 2 h. The washed glass matrix was immersed in a silane chromium hydrolyzate, and the speed of 50 to 150 mm / s was uniform, dried under 60-75 ° C, and the drying time was 90-120 min, and the film was obtained. A bonding layer having a thickness of 6-8 μm.

[0046]First, 26 ml of anhydrous ethanol was taken, 10 ml of tetral titanate and 1.58 ml of ice acetic acid were first added thereto, sealed, magnetic force for 1 h, and the stirring temperature was 25 ° C, and the resulting mixture was car...

Embodiment 2

[0049]Wash the glass matrix, the cleaning step is to clean the glass sheet in the order of deionized water, acetone, anhydrous ethanol and deionized water, and then cleaned 10-15 min, then put the cleaning slide after cleaning In the drying box, dried at 100 ° C to be used.

[0050]Silicon group R '(CH2NSI (OR)3The aqueous solution was added to the magnesium hydroxide to control the GROH molar ratio of 2: 1. The SiOH group released by the alkyl hydrolysis is shrinking with magnesium hydroxide: SiOH + MgOH = Siomg + H2O, stir for 2 h. The water washed and dried, immersed in the silane magnesium hydrolyzate, and eliminated at 50 to 150 mm / s speed, dried under 50-75 ° C, drying time of 60-90 min, obtained film A bonding layer having a thickness of 5-8 μm.

[0051]First, 26 ml of anhydrous ethanol was taken, 10 ml of tetral titanate and 1.58 ml of ice acetic acid were first added thereto, sealed, magnetic force for 1 h, and the stirring temperature was 25 ° C, and the resulting mixture was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com