Perovskite solar cell preparation method based on magnetron sputtering zinc oxide/stannic oxide double electron transport layer

A solar cell and dual electron transfer technology, applied in the field of solar cells, can solve problems such as high cost and restrict long-term development, and achieve the effects of high carrier mobility, high photoelectric conversion efficiency, and improved open circuit voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

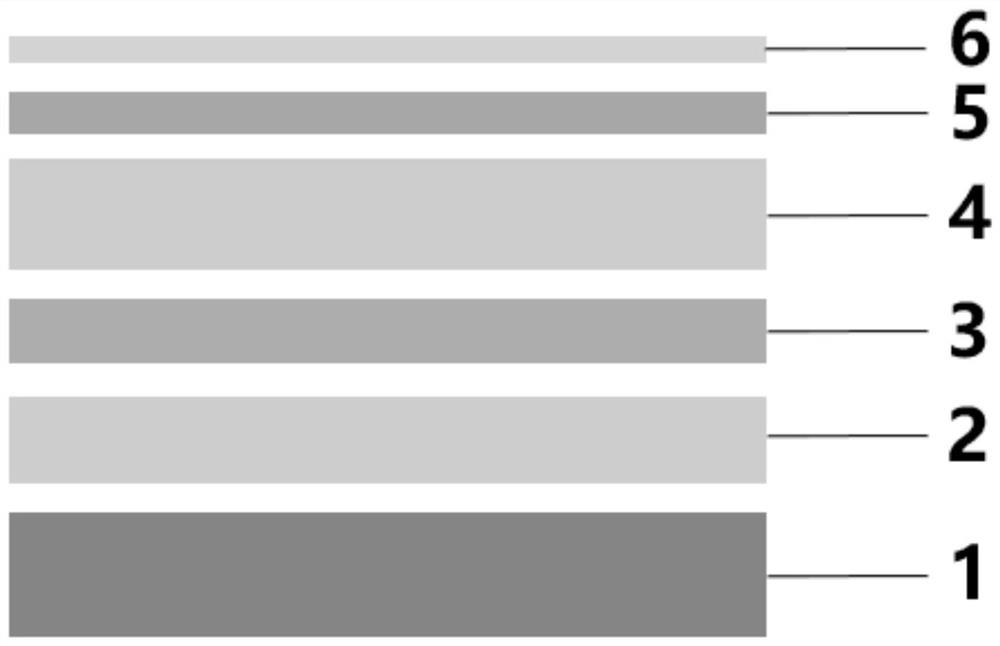

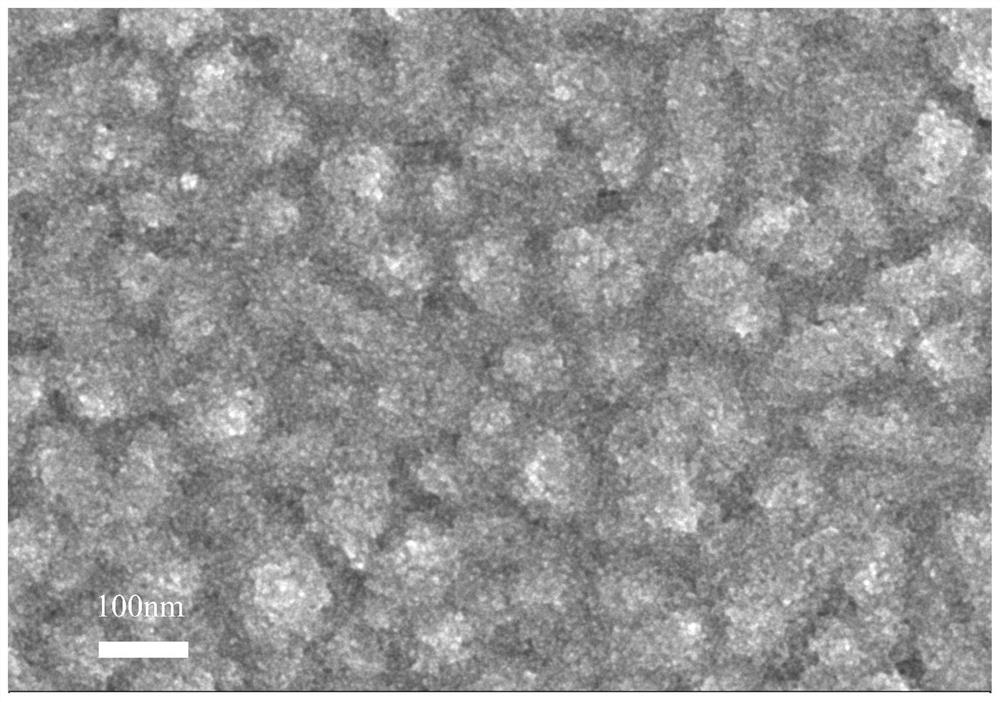

[0030] 1. Put the zinc oxide target in the cavity, fix the FTO conductive glass on the target, close the cavity, vacuumize, adjust the oxygen to 6.0-8.0sccm, argon to 45-55sccm, and the air pressure ratio to 1-3pa. Turn on the bipolar pulse power supply, select a sputtering time of 1-6 minutes; take it out of the chamber after sputtering is completed;

[0031] 2. Spin-coat the perovskite layer and the hole layer based on the magnetron sputtering zinc oxide single electron transport layer obtained in the step, and finally evaporate the silver electrode to obtain the calcium oxide based on the magnetron sputtering zinc oxide single electron transport layer. Titanium solar cells.

[0032] The preparation process of the perovskite light-absorbing layer is: take 0.461g of lead iodide (PbI 2 ) and 0.159 g of methylamine iodide (CH 3 NH 3 1) Put the drug into a brown bottle, add 635ul of dimethylformamide (DMF) and 72ul of dimethyl sulfoxide (DMSO) dropwise to the bottle with a pi...

Embodiment 2

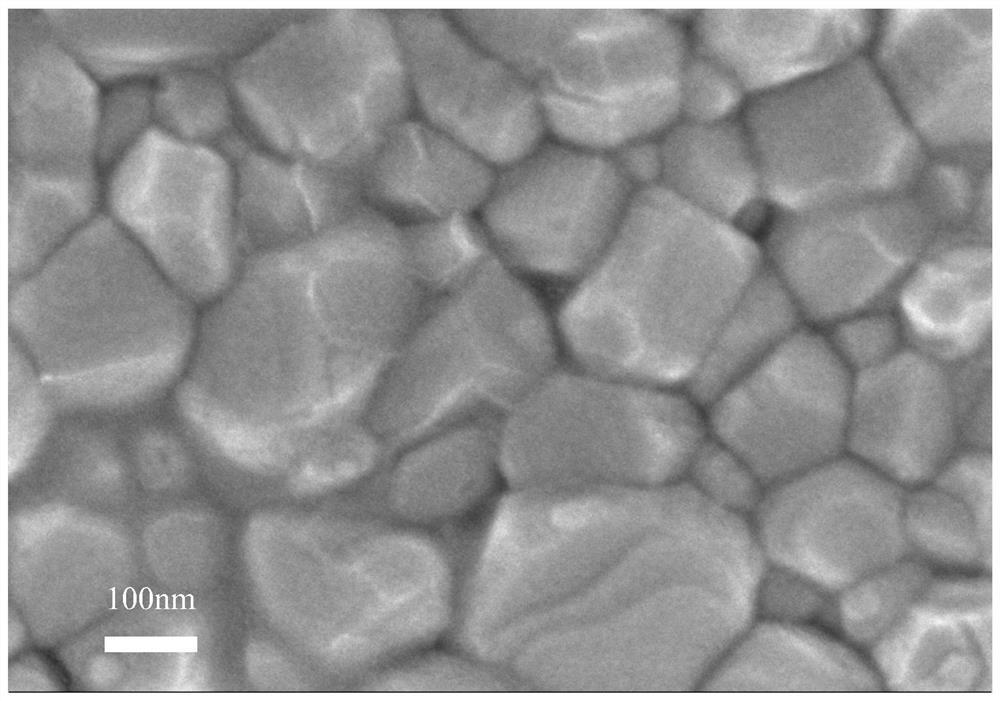

[0039] 1. Put the zinc oxide target in the cavity, fix the FTO conductive glass on the target, close the cavity, vacuumize, adjust the oxygen to 6.0-8.0, argon to 45-55, and the air pressure ratio to 1-3pa. Turn on the bipolar pulse power supply, select the sputtering time for 2 minutes; take it out of the chamber after sputtering is completed;

[0040] 2. The film prepared in step 1 is spin-coated with a tin dioxide solution at 3000rmp / 30s, and annealed at 120°C-180°C in air for 30 minutes, so as to obtain a layer of tin dioxide film on the surface of zinc oxide;

[0041] The tin dioxide solution is diluted with tin dioxide hydrosol and water at a volume ratio of 1:5-1:9, then stirred for 40 minutes, and filtered to obtain the required tin dioxide solution.

[0042] 3. Spin-coat the perovskite light-absorbing layer and the hole-transporting layer on the tin dioxide-zinc oxide double electron transport layer obtained in step 2, and finally vapor-deposit silver electrodes, ther...

Embodiment 3

[0050] 1. Put the zinc oxide target in the cavity, and fix the FTO conductive glass above the target, adjust the distance between the target and the FTO conductive glass to be 2-9cm, close the cavity, vacuumize, and adjust the oxygen to 6.0-8.0 sccm, argon 45-55sccm, pressure ratio 1-3pa. Turn on the bipolar pulse power supply, select the sputtering time for 2 minutes; take it out of the chamber after sputtering is completed;

[0051] 2. Spin-coat the film prepared in step 1 with a tin dioxide solution at 3000rmp / 30s, and anneal it in air at 150°C for 30 minutes, so as to obtain a layer of tin dioxide film on the surface of zinc oxide;

[0052] The tin dioxide solution is diluted with tin dioxide hydrosol and water at a volume ratio of 1:5-1:9, then stirred for 40 minutes, and filtered to obtain the required tin dioxide solution.

[0053] 3. Spin-coat the perovskite layer and the hole layer on the double electron transport layer based on tin dioxide and magnetron sputtering z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com