Elastic-tough well cementation cement paste suitable for coalbed methane and preparation method thereof

A cementing cement slurry and coalbed methane technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of limited ability to modify the elastic modulus of cement stone, short transition time, and inability to promote large-scale applications. Achieve the effect of adjustable thickening time, good stability and flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the elastic-ductile well cementing slurry, comprising: S1) mixing nanoparticles, fibers, and water-soluble resin with water to obtain a liquid phase; S2) mixing oil well cement with the liquid phase to obtain Elastic and ductile cementing cement slurry suitable for coalbed methane.

[0047] In the present invention, there is no special limitation on the types of all raw materials, as long as they are commercially available; wherein, the nanoparticles, fibers, water-soluble resin, water and oil well cement are all the same as those described above, and will not be repeated here.

[0048] In the present invention, it is preferred to firstly mix the nanoparticles with water, ultrasonically disperse them, then add fibers and water-soluble resins, more preferably also add defoamers, fluid loss reducers and dispersants to obtain a liquid phase; the defoamers , fluid loss reducing agent and dispersant are all the same ...

Embodiment 1

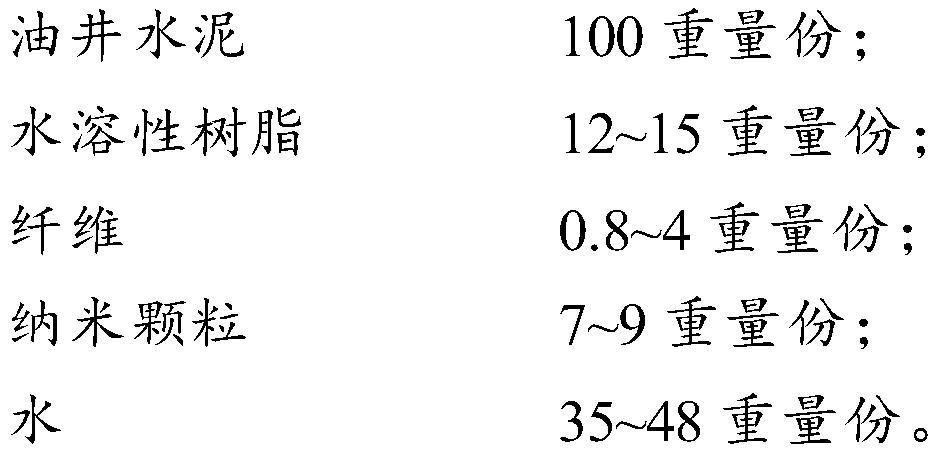

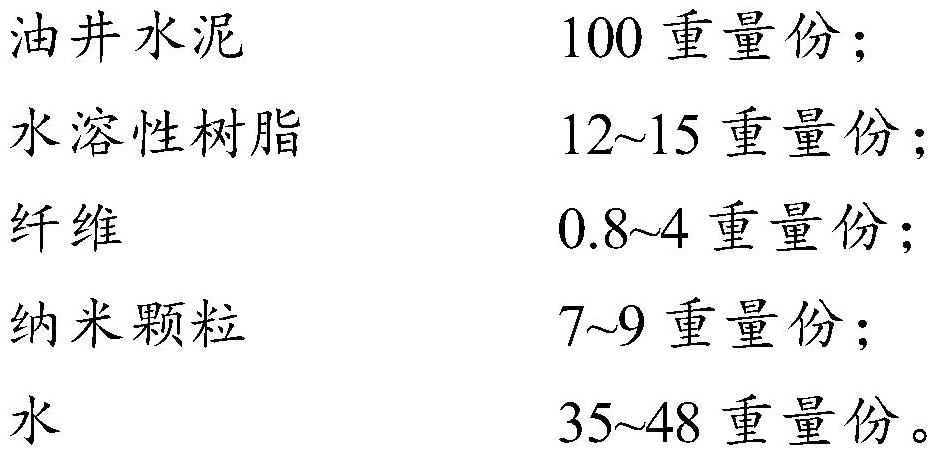

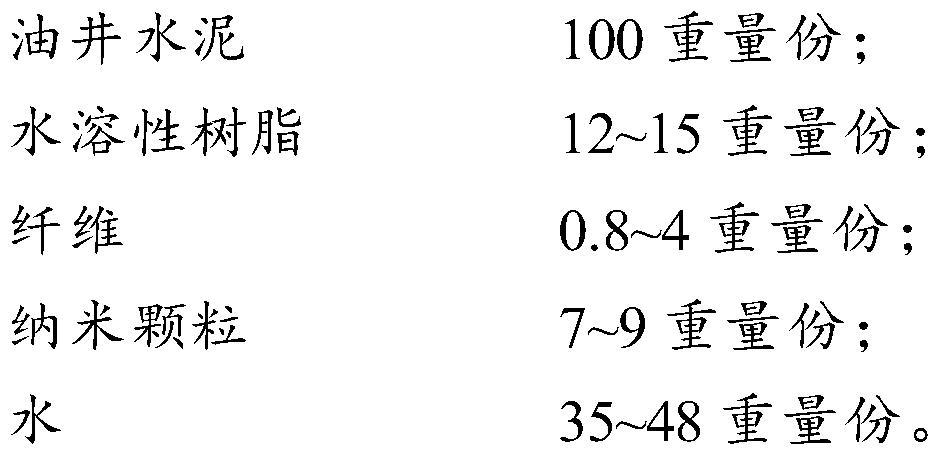

[0067] 35 parts by mass of clear water, then 7 parts by mass of nanoparticles were added to water, and dispersed by ultrasonic waves (power 1000W) for 40 minutes; then 0.8 parts by mass of mixed fiber material (basalt fiber and lignin fiber with a mass ratio of 1:2.5), 12 Parts by mass of resin material, 0.7 parts by mass of dispersant, 2.1 parts by mass of fluid loss reducer, and 0.4 parts by mass of defoamer are dissolved in water in sequence; next, pour 100 parts by mass of cement ash into the liquid phase, Stir evenly to form an elastic-ductile cement slurry system, marked as S1.

Embodiment 2

[0069] The cement slurry system is prepared in the same steps as in Example 1, the difference is that the mass fraction of clear water is 48, the mass fraction of resin material is 15, and the mass fraction of mixed fiber is 4 (basalt with a mass ratio of 1:2 fiber and lignin fiber), the mass fraction of nanoparticles is 9, the mass fraction of dispersant is 1.4, the mass fraction of fluid loss reducer is 4.7, and the mass fraction of defoamer is 1.

[0070] This step forms an elastic-ductile cement slurry system, marked as S2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com