Microbial flocculant for clarifying brewed vinegar and preparation method and application thereof

A microbial flocculant, a technology for brewing vinegar, applied in the field of microbial engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Paenibacillus castaneae was first activated on the test tube slant before inoculation, and cultivated at 28°C for 48 hours. The slant medium used for cultivation consisted of: 2.0% soluble starch, 0.5% peptone, 0.05% potassium chloride, hydrogen phosphate Dipotassium 0.1%, magnesium sulfate 0.05%, agar 2.0%, pH 7.0; Then the bacterial cells were washed with sterile water and inserted into a triangular flask (500mL) containing 100mL seed culture solution for seed culture (cultivated at 28°C for 30 hours ), the medium is 1.0% soluble starch, 1.5% sucrose, 0.5% peptone, 0.05% potassium chloride, 0.1% dipotassium hydrogen phosphate, and 0.05% magnesium sulfate. After the seed growth is completed, the microscopic examination is free of bacteria for later use.

[0025] 7L of fermentation medium was prepared, and the formula of the medium was 3.0% of glucose, 0.1% of sodium nitrate, 0.3% of peptone, 0.05% of potassium chloride, 0.1% of dipotassium hydrogen phosphate, and 0.05%...

Embodiment 2

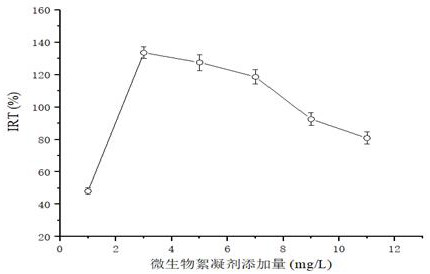

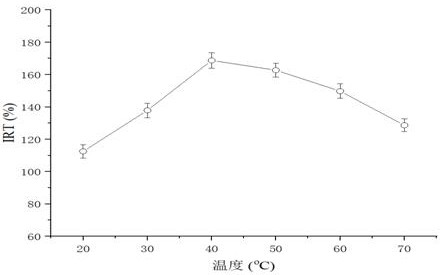

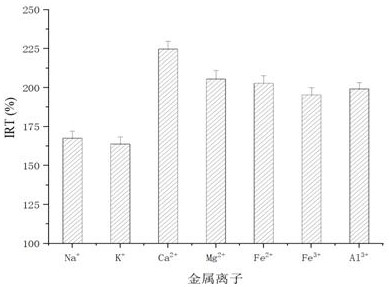

[0028] Example 2: Optimization of microbial flocculant application conditions in brewing vinegar

[0029] 1. Method for determination of flocculation effect of vinegar

[0030] The submerged liquid fermented vinegar was collected, and the permeability was used as an index to measure the flocculation effect of the purified bioflocculant in rice vinegar. Add 1 mL of the purified bioflocculant solution to 100 mL of rice vinegar. Stir for 2 minutes, let stand for 10 minutes, and take the supernatant for analysis. The transmittance of the supernatant was measured at a wavelength of 900 nm. The control group was prepared according to the same process except that the sample solution was used instead of distilled water.

[0031]The increase rate of transmittance (Increase rate of transmittance, IRT) is calculated as follows:

[0032]

[0033] A: initial value; B: value after flocculation treatment

[0034] 2. Single factor optimization method for vinegar flocculation condition...

Embodiment 3

[0050] Embodiment 3: the product safety test that the inventive method prepares

[0051] 1. Acute oral toxicity test in mice

[0052] Evenly disperse the prepared sample homogenizer in distilled water at 70°C, and prepare the concentration to be 0.1g·ml -1 solution, cooled to 40°C for later use. Select clean-grade ICR mice, weighing 18-24g, 10 males and 10 males, fasted for 16 hours before gavage, and give the test substance three times within 24 hours after weighing, with a gavage volume of 40ml kg -1 , with a cumulative total dose of 12 g·kg -1 . They were given food 4 hours after gavage, observed continuously for 14 days, and recorded the symptoms of poisoning and death.

[0053] Table 3 Body weight gain record of acute toxicity mice

[0054]

[0055] Note: * is significantly different from the control group (P<0.05), ** is very significantly different from the control group (P<0.01)

[0056] After administration, the mice had bright coat, no excitement, restlessne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com