Triarylethene photochromic material, method and application of triarylethene photochromic material as 3D printing ink

A photochromic material, triarylethene technology, applied in the field of color-changing materials, can solve problems such as narrow application range and difficulty in applying complex models, and achieve the effect of easy purification, good stability, and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1: Synthesis of intermediate ylide reagent 4-methyl formate diethyl phenylphosphate

[0038]

[0039]Methyl 4-bromomethylbenzoate (4.60 g, 20.06 mmol) and triethyl phosphite (10.00 g, 60.18 mmol) were added to a 250 ml flask. The initial suspension in the flask was heated above 80°C to reflux on a magnetic stirrer. After refluxing for 12 hours, it was cooled to room temperature, and excess triethyl phosphite was removed by distillation under reduced pressure. After cooling, a solid precipitated from the remaining stock solution, which was washed with n-hexane, filtered and dried to obtain 5.05 g of ylide reagent 4-methyl formate diethyl phenylphosphate with a yield of 87.94%.

[0040] Failure case(1)

[0041] Methyl 4-bromomethylbenzoate (2.30 g, 10.03 mmol) and triethyl phosphite (5.00 g, 30.09 mmol) were added to a 250 ml flask. The initial suspension in the flask was heated to 50 degrees Celsius on a magnetic stirrer, and after 12 hours, it was cooled to r...

Embodiment 3

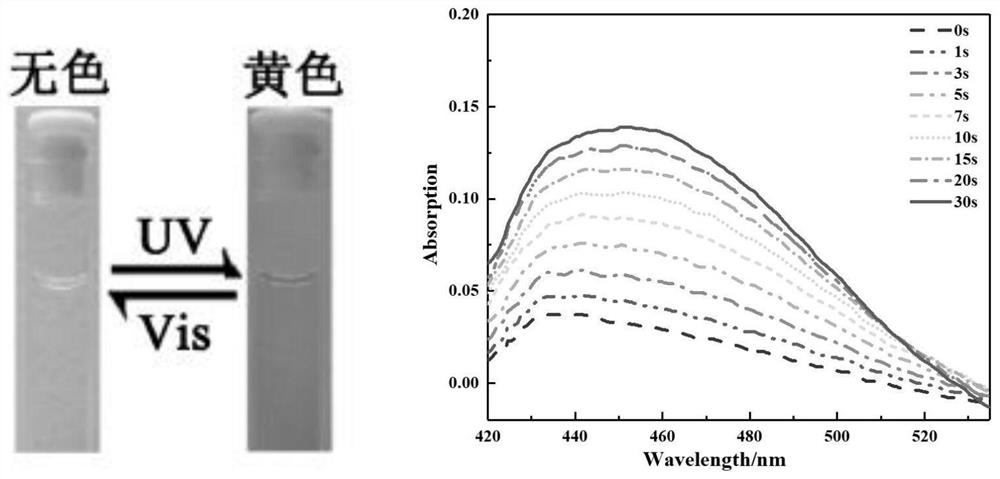

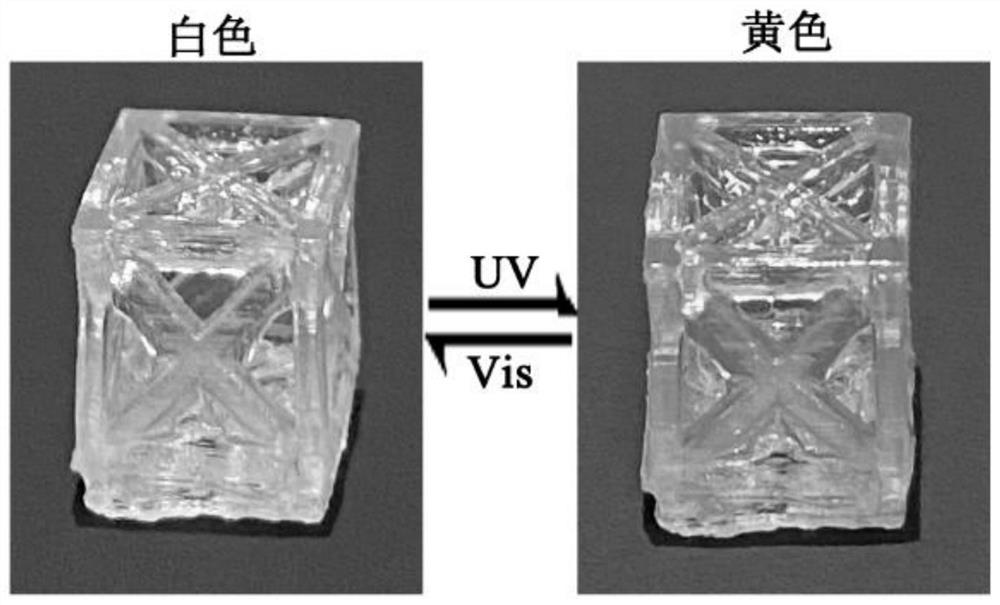

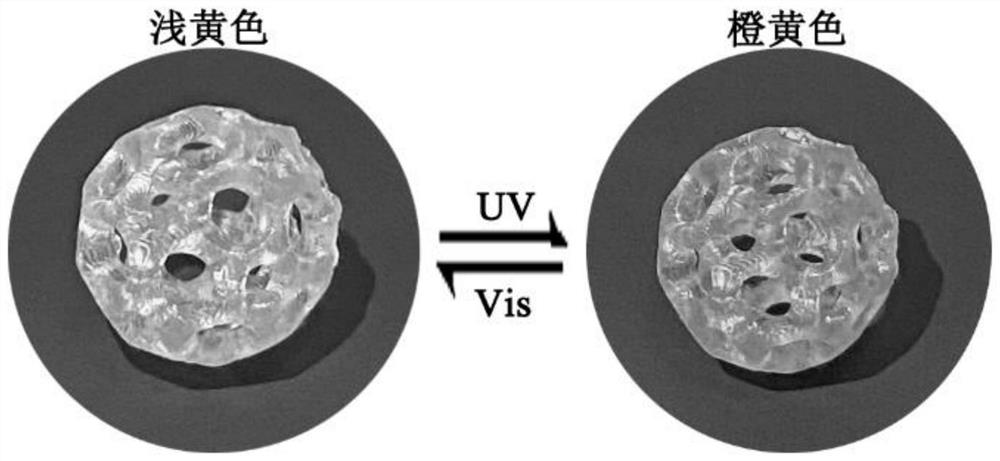

[0061] Mix the monomer of polyethylene glycol (diol) diacrylate (molecular weight 575) with the target product methyl methacrylate triarylethylene in Example 1 according to the mass fraction of 20:1, and then add a certain amount of tetrahydrofuran (THF ) solution and 5wt% photoinitiator diphenyl-(2,4,6-trimethylbenzoyl)phosphine (TPO) were fully stirred evenly as 3D printing ink. The prepared 3D inks are then used to print complex 3D structures on a custom-made high-resolution 3D printing system. The exposure time was 2 seconds, and the thickness of each layer was 50 mm. After the printing is completed, the unreacted monomer and crosslinking agent on the surface of the printed 3D structure are removed with a rubber suction ball. Finally, the structure was post-cured in a UV oven.

[0062] Table 1: final product in the embodiment in the maximum discoloration ultraviolet absorption wavelength and stimulus response condition

[0063] compound photochromic effect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| photochromic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com