Process design for reducing impedance of silicon monoxide-graphite negative electrode and impedance diagnosis method

A silicon oxide and graphite anode technology, applied in the field of lithium-ion batteries, can solve the problem of insufficient charge data, provide an intuitive and accurate data reference, poor consistency and reliability of test data, and it is difficult to accurately express the silicon carbon anode material. Specific capacity contribution and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

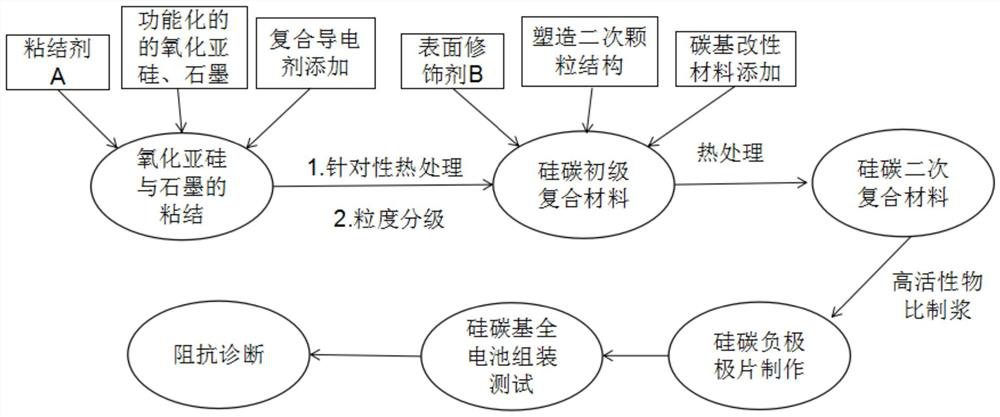

[0033] The process design for reducing the silicon oxide-graphite composite negative electrode impedance described in Example 1 is as follows:

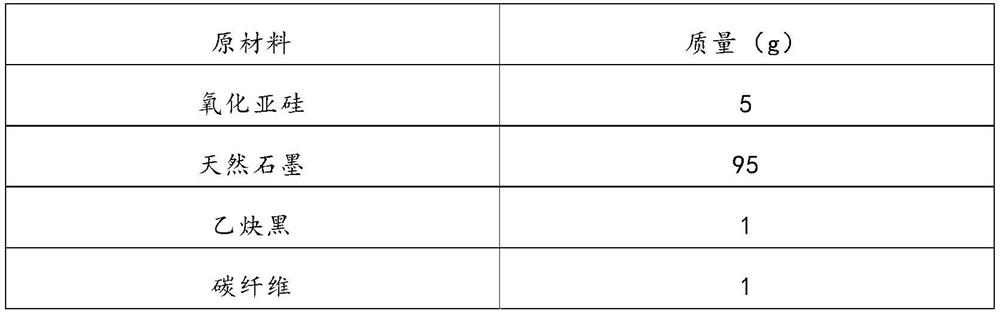

[0034] The various raw materials and their corresponding mass distributions are shown in the table below:

[0035]

[0036]

[0037] 1) First, silicon oxide and natural graphite with a particle size of 3 to 5 microns and amorphous carbon deposition on the surface are added to the binder A petroleum asphalt, and mixed evenly by a jet mixer;

[0038] 2) Then add the compound of granular acetylene black and nanowire carbon fiber, and mix again through ball mill equipment to ensure uniform dispersion of materials;

[0039] 3) Then heat treatment at 400°C to 1000°C for 1h to 5h under a protective atmosphere of hydrogen-argon mixed gas (hydrogen gas fraction 5%) to obtain a primary silicon-carbon composite material;

[0040] 4) Then import the silicon-carbon primary composite material into the fusion machine equipment with the abilit...

Embodiment 2

[0049] The process design for reducing the silicon oxide-graphite composite negative electrode impedance described in Example 2 is as follows:

[0050] The various raw materials and their corresponding mass distributions are shown in the table below:

[0051] raw material mass (g) Silicon oxide 6 artificial graphite 94 Super P 2 carbon nanotubes 2 Phenolic Resin 8 asphalt 4

[0052] 1) First, silicon oxide and artificial graphite with a particle size of 5 to 10 microns are added to the binder A phenolic resin, and mixed uniformly by a ball mill;

[0053] 2) Then add the compound of granular Super P and nanowire-shaped carbon nanotubes, and mix again through ball mill equipment to ensure uniform dispersion of materials;

[0054] 3) Then heat treatment at 700°C to 900°C for 1h to 8h under a protective atmosphere of hydrogen-argon mixed gas (hydrogen gas fraction: 2%) to obtain a silicon-carbon primary composite material;

[0...

Embodiment 3

[0063] The process design for reducing the silicon oxide-graphite composite negative electrode impedance described in Example 3 is as follows:

[0064] The various raw materials and their corresponding mass distributions are shown in the table below:

[0065] raw material mass (g) Silicon oxide 8 artificial graphite 82 natural graphite 10 carbon fiber 2 Polycyclic aromatic derivatives 8 PVC 10

[0066] 1) First, add silicon oxide, artificial graphite, and natural graphite with a particle size of 9 to 12 microns pre-lithiated on the surface into the binder A phenolic resin, and mix them uniformly through a pot mill;

[0067] 2) Then add the carbon fiber composite, and mix again through the airflow mixer equipment to ensure that the material is uniformly dispersed;

[0068] 3) Then heat treatment at 500°C to 800°C for 1h to 5h under a nitrogen protective atmosphere to obtain a primary silicon-carbon composite material;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com