Method for modifying polymer porous membrane by diffusion reaction

A diffusion reaction and polymer technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as easy loss of surfactants, hydrophilicity cannot be kept stable for a long time, and membrane adsorption pollution increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

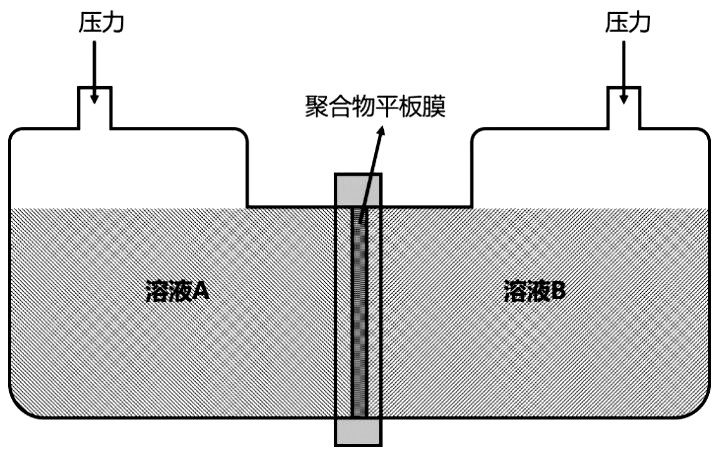

[0022] 1) Prepare an aqueous solution of sodium dodecylsulfonate with a mass percentage concentration of 0.05%, soak a clean polypropylene flat film in it, soak at a temperature of 50°C, and soak for 10 hours. The aqueous solution of sodium sulfonate is evenly distributed on the surface of the polypropylene flat membrane and its pores;

[0023] 2) Take out the coated polypropylene membrane, fix it in the diffusion cell, and add the aqueous solutions of aluminum nitrate and sodium carbonate on both sides of the membrane respectively, the concentration is 0.6 mol / liter, and the two reaction solutions diffuse through the membrane pores, The diffusion reaction was carried out at 30°C for 5 hours.

[0024] 3) After the diffusion reaction is completed, the polypropylene membrane is taken out from the diffusion cell, and washed repeatedly in ethanol and pure water to obtain a modified polypropylene membrane.

Embodiment 2

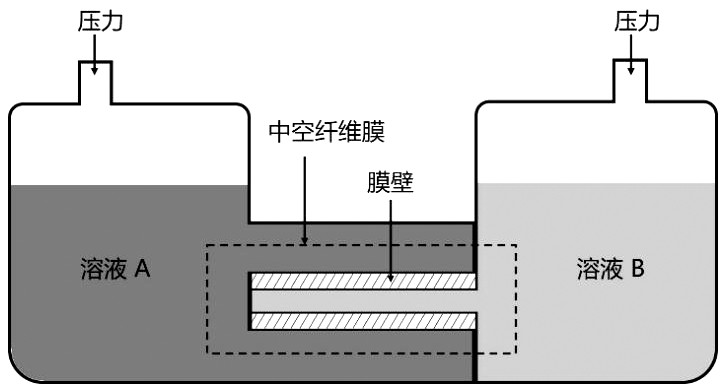

[0026] 1) Prepare an ethanol solution of tannic acid with a mass percentage concentration of 5%, soak the clean polyvinylidene fluoride hollow fiber in it, the soaking temperature is 10°C, and the soaking time is 40 hours. The ethanol solution is evenly distributed on the surface of the polyvinylidene fluoride hollow fiber membrane and its pores;

[0027] 2) Take out the coated polyvinylidene fluoride membrane, fix it in the diffusion cell, and add the aqueous solution of magnesium chloride and sodium bicarbonate on both sides of the membrane respectively, the concentration is 0.3 mol / liter, and the two reaction solutions pass through the pores of the membrane to interact with each other. Diffusion, the diffusion reaction was carried out at 10°C for 40 hours.

[0028] 3) After the diffusion reaction is completed, the polyvinylidene fluoride membrane is taken out from the diffusion cell, and washed repeatedly in ethanol and pure water to obtain a modified polyvinylidene fluorid...

Embodiment 3

[0030] 1) Prepare an ethanol solution of silanol with a mass percentage concentration of 0.1%, soak the clean polytetrafluoroethylene flat film in it, the soaking temperature is 20°C, and the soaking time is 24 hours, and the ethanol solution of silanol is made by ultrasonic Evenly distributed on the surface of PTFE flat membrane and its pores;

[0031] 2) Take out the coated polytetrafluoroethylene flat film, fix it in the diffusion cell, and add the aqueous solution of silicon tetrachloride and sodium hydroxide on both sides of the film, the concentration is 0.01 mol / L, and the two reaction solutions Interdiffusion through the membrane pores was carried out at 80°C for 10 hours.

[0032] 3) After the diffusion reaction is completed, the polytetrafluoroethylene membrane is taken out from the diffusion cell, and washed repeatedly in ethanol and pure water to obtain a modified polytetrafluoroethylene membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com