High-throughput preparation method of gravity infiltration composite lining plate

A composite liner, high-throughput technology, applied in metal processing equipment, coating, transportation and packaging, etc., to improve efficiency, improve research and development and preparation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

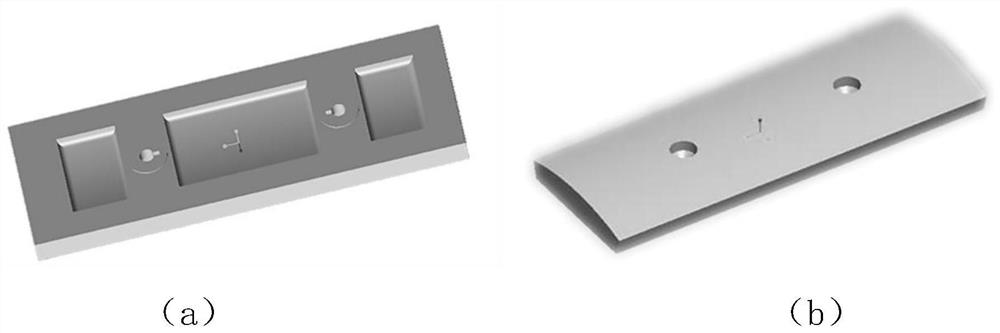

[0036] A high-throughput preparation method of a gravity impregnation composite liner of the present invention comprises the following steps:

[0037] S1. Surface modification of zirconia-toughened alumina ceramic particles, respectively plating titanium-nickel alloy layers by salt bath titanium plating and electroless nickel plating, to form a structure of inner titanium and outer nickel;

[0038] In the composition of zirconia toughened alumina ceramic particles, Al 2 o 3 20wt.%~80wt.%, the balance is ZrO 2 .

[0039] The main raw materials used in salt bath titanium plating are titanium powder with a particle size of 20-100 mesh and active halogen salts, and alkaline or neutral plating solution is used for electroless nickel plating. The thickness ratio of the titanium layer to the nickel layer of the surface-modified zirconia-toughened alumina ceramic particles is about 1:3, and the total coating thickness is 10-50 microns.

[0040] S2. Evenly mix the surface-modified zi...

Embodiment 1

[0049] 1) to Al 2 o 3 The zirconia toughened alumina ceramic particles with a mass fraction of 20% are surface-modified, 400-mesh titanium powder is used for salt bath titanium plating, and the titanium-plated particles are electroless nickel-plated with an alkaline plating solution, respectively plating 10 microns Titanium layer, 30 micron nickel layer;

[0050] 2) Evenly mix surface-modified zirconia toughened alumina ceramic particles with nickel-titanium alloy powder, wherein the amount of alloy powder accounts for 5% of the mass fraction of ZTA ceramic particles, place the mixed particles in a graphite mold and press In fact, the macroscopic pore diameter is

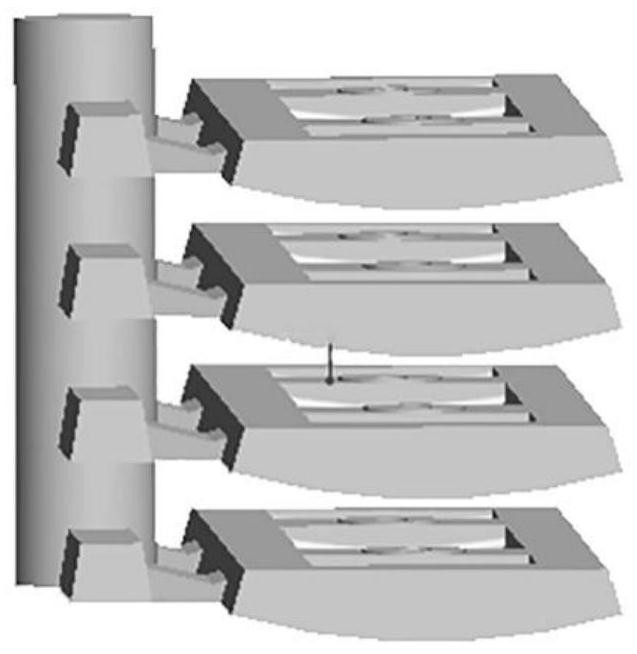

[0051] 3) Put graphite molds into a high-throughput non-pressure atmosphere sintering furnace, place 3×18 graphite molds at a time, and put in a protective atmosphere after vacuuming, control the heating rate to 15°C / min, and the sintering temperature to 1250°C. Keep warm for 2 hours to sinter a ceramic particl...

Embodiment 2

[0055] 1) to Al 2 o 3 Zirconia toughened alumina ceramic particles with a mass fraction of 40% are surface-modified, 400 mesh titanium powder is used for salt bath titanium plating, and alkaline plating solution is used to electroless nickel-plate the titanium-plated particles, respectively plating 10 microns Titanium layer, 30 micron nickel layer;

[0056] 2) Evenly mix surface-modified zirconia toughened alumina ceramic particles with nickel-titanium alloy powder, wherein the amount of alloy powder accounts for 10% of the mass fraction of ZTA ceramic particles, place the mixed particles in a graphite mold and press Real, macroscopic pore diameter size

[0057] 3) Put graphite molds into a high-throughput non-pressure atmosphere sintering furnace, place 3×24 graphite molds at a time, and put in a protective atmosphere after vacuuming, control the heating rate to 20°C / min, and the sintering temperature to 1300°C. Keep warm for 1 hour to sinter a ceramic particle prefabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com