Method for producing biological aviation kerosene by adopting liquid catalytic process

A liquid catalytic and biological technology, applied in chemical instruments and methods, hydroprocessing technology, chemical/physical processes, etc., can solve the problems of poor dispersion of heterogeneous catalysts, influence of catalyst activity, catalyst coking, etc., to achieve easier industrialization and process Green, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of liquid catalyst:

[0022] The mass ratio of niobium oxalate: ammonium molybdate: nickel oxalate: ammonium metatungstate: water = 2:2:10:2:10 is made into a mixed solution, and the liquid catalyst is obtained by stirring evenly.

[0023] The production process of bio-jet fuel:

[0024] (1) Mix the soybean oil and the synthesized liquid catalyst according to the mass ratio of 1000:1 and stir evenly with a stirrer, then pump the uniformly mixed raw materials into the suspension slurry bed for hydrogenation reaction, the reaction temperature is 250°C, the reaction The pressure is 6MPa; (2) The hydrogenation reactant is injected into the centrifuge for separation, and the residue is collected; (3) The deslagging liquid is injected into the bio-jet fuel hydrocracking reactor at a reaction temperature of 350°C and a reaction pressure of 8MPa (4) Distilling the hydrocracking product to obtain bio-jet fuel at 150-280°C and biomass light solvent oil below 150°C. ...

Embodiment 2

[0026] Preparation of liquid catalyst:

[0027] The mass ratio of niobium oxalate: ammonium metatungstate: nickel oxalate: cobalt oxalate: water = 2:2:5:5:10 is made into a mixed solution, and the liquid catalyst is obtained by stirring evenly.

[0028] The production process of bio-jet fuel:

[0029] (1) Mix the rice bran oil and the synthesized liquid catalyst at a mass ratio of 500:1 and stir evenly with a stirrer, then pump the uniformly mixed raw materials into the suspension slurry bed for hydrogenation reaction, and the reaction temperature is 280°C. The pressure is 4MPa; (2) The hydrogenation reactant is injected into the centrifuge for separation, and the residue is collected; (3) The deslagging liquid is injected into the bio-jet hydrocracking reactor at a reaction temperature of 400°C and a reaction pressure of 6MPa. (4) Distilling the hydrocracking product to obtain bio-jet fuel at 150-280°C and biomass light solvent oil below 150°C.

Embodiment 3

[0031] Preparation of liquid catalyst:

[0032] The mass ratio of niobium oxalate: ammonium molybdate: iron oxalate: ruthenium nitrate: water = 3:2:8:1:10 is made into a mixed solution, and the liquid catalyst is obtained by stirring evenly.

[0033] The production process of bio-jet fuel:

[0034] (1) Mix the waste oil and the synthesized liquid catalyst according to the mass ratio of 300:1 and stir evenly with a stirrer, then pump the evenly mixed raw materials into the suspension slurry bed for hydrogenation reaction, the reaction temperature is 260°C, and the reaction The pressure is 5MPa; (2) The hydrogenation reactant is injected into the centrifuge for separation, and the residue is collected; (3) The deslagging liquid is injected into the bio-jet hydrocracking reactor at a reaction temperature of 390°C and a reaction pressure of 12MPa. (4) Distilling the hydrocracking product to obtain bio-jet fuel at 150-280°C and biomass light solvent oil below 150°C.

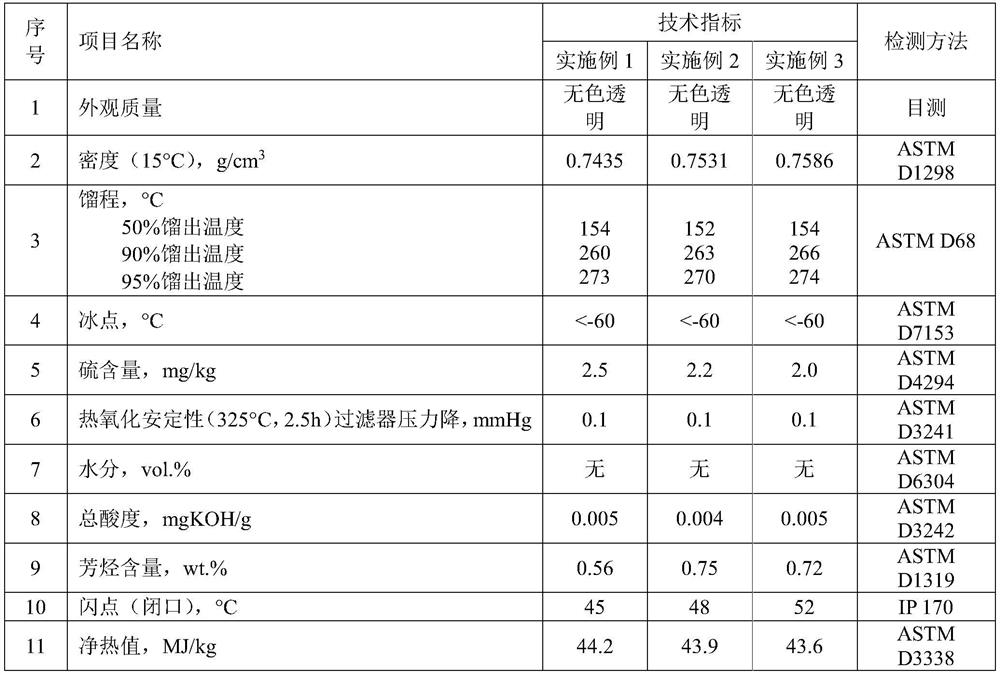

[0035] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com