Photoelectric detector employing gate modulation graphene/semiconductor Schottky junction and preparation method

A photodetector and semiconductor technology, applied in the field of photodetectors, can solve the problems of long response time, easy generation of dark current, carrier collection efficiency, low migration rate, etc., so as to reduce dark current and increase photocurrent. and responsiveness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

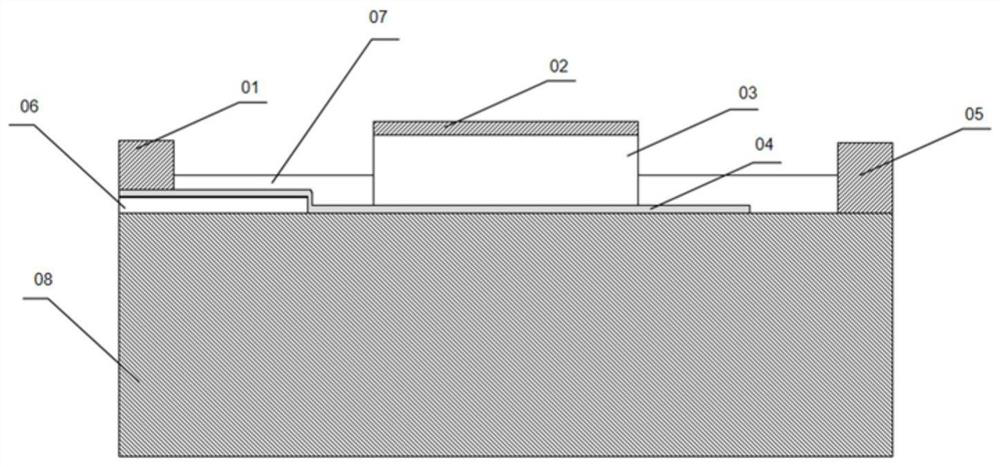

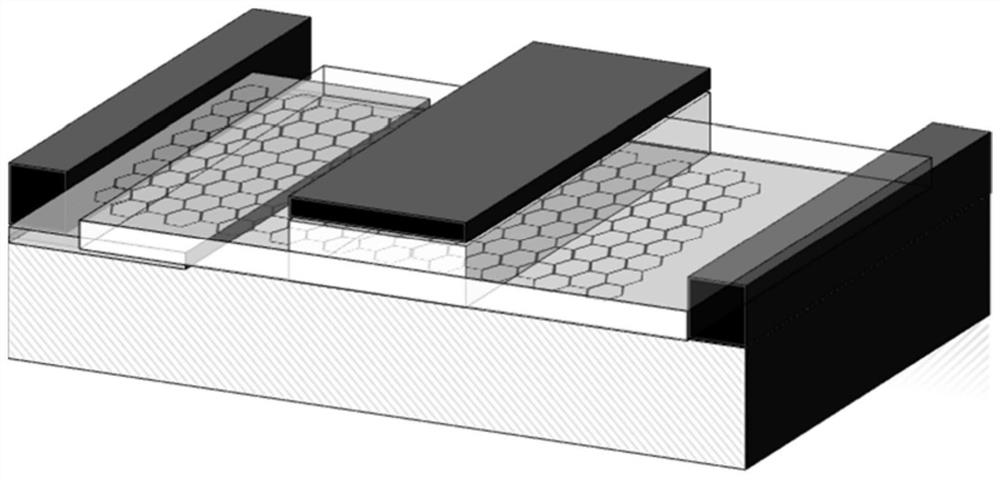

[0041] Such as figure 1 and figure 2 As shown, a photodetector adopting gate modulation graphene / semiconductor Schottky junction includes a substrate 08, a semiconductor layer is arranged on the substrate, and the insulating layer 06 is arranged on the semiconductor layer, and only covers the semiconductor layer A part of the area, the present embodiment 1 specifically covers the left part of the semiconductor layer, as an insulating layer that isolates a part of the graphene from contacting the semiconductor layer, and provides a platform for the graphene to contact the electrode, and its shape can change according to the requirements of the electrode. The graphene layer 04 is arranged on the insulating layer and part of the semiconductor layer, and the length ratio of the graphene on the insulating layer and on the semiconductor layer is 1:2-1:3; the transparent passivation layer 07 and the piezoelectric gate layer 03 is set on the graphene layer, the first metal electrode...

Embodiment 2

[0050] Such as Figure 3-Figure 7 Shown, the preparation method of above-mentioned embodiment 1 photodetector, comprises the steps:

[0051] (1) The substrate is high-resistance single-crystal silicon with (100) crystal orientation, and a high-quality germanium epitaxial layer with a thickness of 1 μm is grown on the high-resistance single-crystal silicon wafer, and the growth process adopts a two-step method of high temperature and low temperature. First, the received Si(100) substrate was annealed at 900 °C in air for 5 h before growth to obtain an atomically flat surface. Secondly, use ethanol deionized water to clean the substrate surface contamination, and put it into a vacuum of 2.0×10 -10 Torr's ultra-high vacuum MBE chamber. The growth of Ge adopts the solid-source MBE method. First, a ~20nm germanium buffer layer is grown on the Si(100) substrate at 500°C to suppress island growth; then the temperature is raised to 750°C, and the growth thickness is 980nm. Ge layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com