Quinoa protein liquid for fiber compounding and preparation method of quinoa protein fibers

A quinoa protein and fiber composite technology, applied in the direction of cellulose/protein conjugated artificial filament, fiber treatment, filament/thread forming, etc., can solve the problems of no technology, etc., achieve high protein content and breaking strength, combine good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

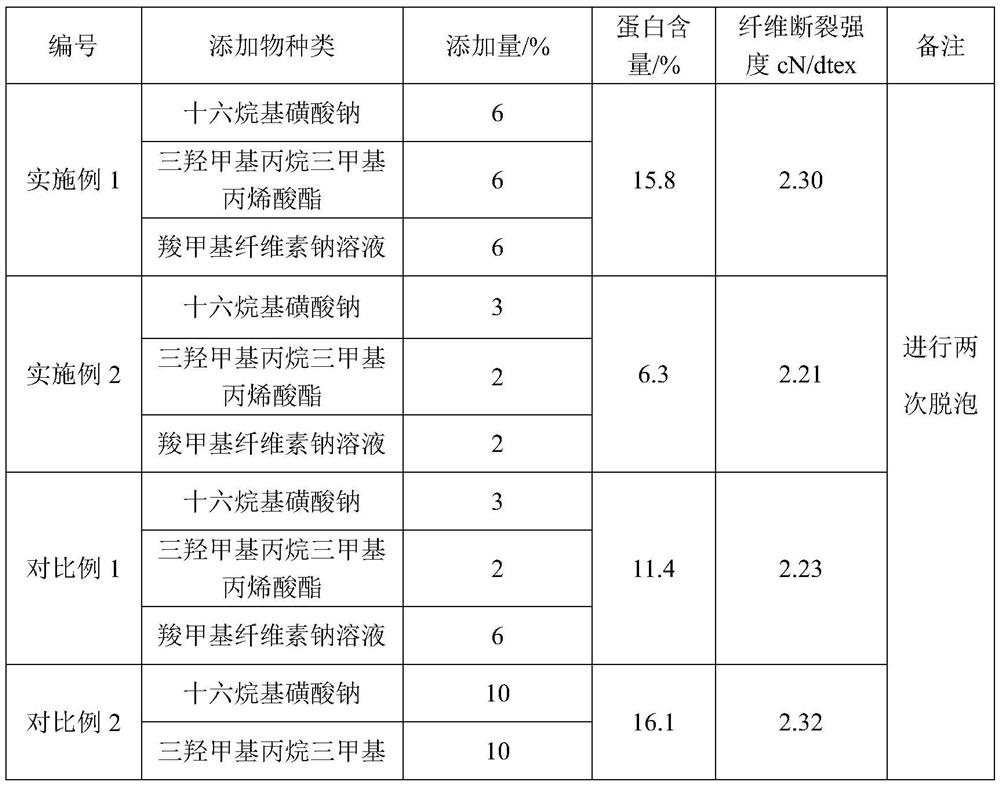

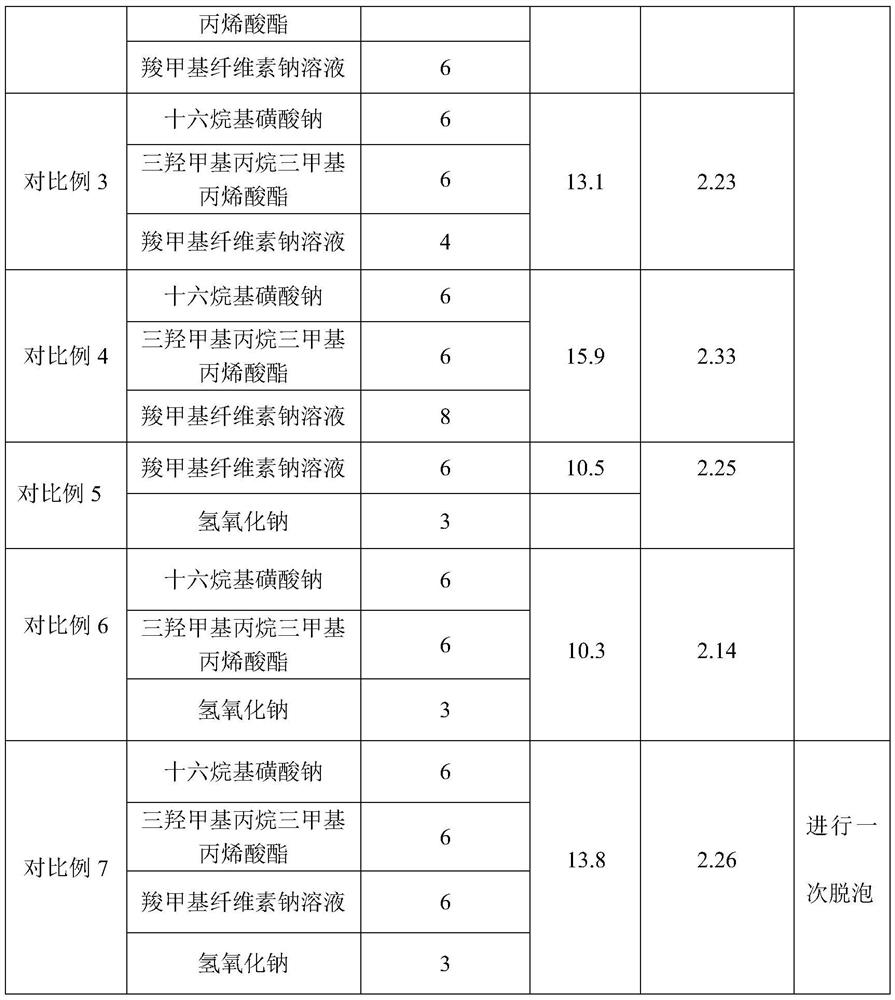

Examples

Embodiment 1

[0036] A preparation method of quinoa protein, comprising the following steps:

[0037] Step 1: Quinoa Pretreatment

[0038] Rinse the quinoa continuously with pure water, drain the water, soak it in hot water for 5 hours, dry it in an oven, add ethanol and mix well, then put it into a grinder for grinding. The ratio of quinoa to ethanol is 1:5 ;

[0039] Step 2: Enzymolysis

[0040]Use sodium hydroxide to adjust PH=9.5-10.5, add 8% alkaline protease to the quinoa protein slurry for hydrolysis, keep warm at 30-35°C for 2 hours, and initially obtain the quinoa protein slurry, and then use dilute acetic acid to adjust the pH to 6.5-7.5 Add 8% amylase and digestive enzymes, the mass ratio of amylase and digestive enzymes is 1:1, keep warm at 30-35°C, fully react for 2 hours, and spray-dry the obtained protein solution to obtain high purity Quinoa protein powder.

[0041] Step 3: Cross-linking modification

[0042] Mix quinoa protein powder with ethanol at a ratio of 1:5, and...

Embodiment 2

[0054] A preparation method of quinoa protein, comprising the following steps:

[0055] Step 1: Quinoa Pretreatment

[0056] Rinse the quinoa continuously with pure water, drain the water, then soak it in hot water for 3 hours, dry it in an oven, add ethanol and mix well, put it into a grinder for grinding, the ratio of quinoa and ethanol is 1:5 ;

[0057] Step 2: Enzymolysis

[0058] Use sodium hydroxide to adjust PH=9.5, add 0.05 alkaline protease of quinoa protein slurry to hydrolyze, keep warm at 30-35°C, initially obtain quinoa protein slurry, then adjust PH to 6.5-7.5 with dilute acetic acid, add amylase and digestive enzymes, keep warm at 30-35°C, fully react for 3 hours, and spray-dry the obtained protein solution to obtain high-purity quinoa protein powder.

[0059] Step 3: Cross-linking modification

[0060] Mix quinoa protein powder with ethanol at a ratio of 1:5, and fully dissolve with 0.8% sodium hydroxide solution. The specific dissolution temperature curve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com