A kind of nano ferroferric oxide/graphene composite Fenton catalytic film and its preparation method and application

A composite technology of ferric oxide and graphene, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the limitations of popularization and application, large chemical sludge, The optimal pH range is narrow and other problems, to achieve the effect of wide applicable pH range, improving utilization efficiency, and inhibiting self-quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

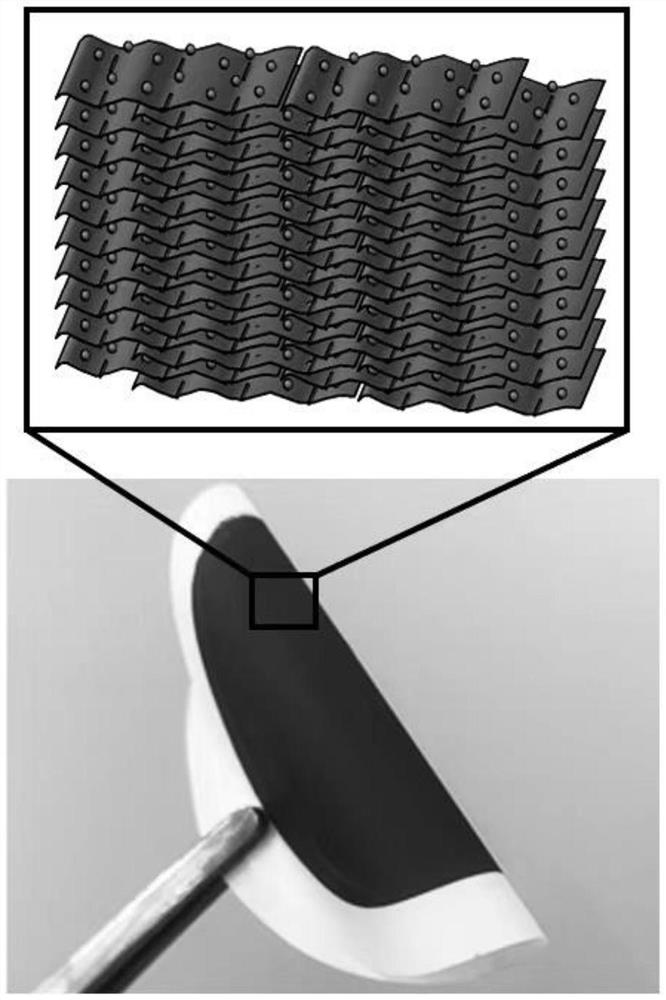

[0029] Preparation of a nano-ferric oxide / graphene composite Fenton catalytic membrane: Disperse 50 mg of single-layer graphene oxide nanosheets in 40 mL of ethylene glycol, add 0.05 g of ferric chloride hexahydrate, 1.8 g of sodium acetate, 0.02 g of sodium citrate, stirred by ultrasound and magnetic force until the solution was uniform, and used solvothermal method at 200°C for 4 hours to make ferric oxide nanoparticles grow in situ on the surface of graphene oxide nanosheets, then naturally cooled to room temperature, and then ethanol, Wash the obtained nano ferric oxide / reduced graphene oxide composite nanomaterial with ion water, dry it in vacuum at 40° C. for 8 hours, and then use it. Disperse 2 mg of composite nanomaterials and 1 mg of palygorskite nanorods in 200 mL of deionized water, mix them uniformly with ultrasound, and filter them onto a polyethersulfone microfiltration membrane, so that the composite nanomaterials and palygorskite self-assemble to form a membrane...

Embodiment 2

[0032] Preparation of a nano-ferric oxide / graphene composite Fenton catalytic membrane: Disperse 50 mg of single-layer graphene oxide nanosheets in 40 mL of ethylene glycol, add 0.10 g of ferric chloride hexahydrate, 1.8 g of sodium acetate, 0.02 g of sodium citrate, stirred by ultrasound and magnetic force until the solution was uniform, and used solvothermal method at 200°C for 4 hours to make ferric oxide nanoparticles grow in situ on the surface of graphene oxide nanosheets, then naturally cooled to room temperature, and then ethanol, Wash the obtained nano ferric oxide / reduced graphene oxide composite nanomaterial with ion water, dry it in vacuum at 40° C. for 8 hours, and then use it. Disperse 2 mg of composite nanomaterials and 1 mg of palygorskite nanorods in 200 mL of deionized water, mix them uniformly with ultrasound, and filter them onto a polyethersulfone microfiltration membrane, so that the composite nanomaterials and palygorskite self-assemble to form a membrane...

Embodiment 3

[0035] Preparation of a nano-ferric oxide / graphene composite Fenton catalytic membrane: Disperse 50 mg of single-layer graphene oxide nanosheets in 40 mL of ethylene glycol, add 0.15 g of ferric chloride hexahydrate, 1.8 g of sodium acetate, 0.02 g of sodium citrate, stirred by ultrasound and magnetic force until the solution was uniform, and used solvothermal method at 200°C for 4 hours to make ferric oxide nanoparticles grow in situ on the surface of graphene oxide nanosheets, then naturally cooled to room temperature, and then ethanol, Wash the obtained nano ferric oxide / reduced graphene oxide composite nanomaterial with ion water, dry it in vacuum at 40° C. for 8 hours, and then use it. Disperse 2 mg of composite nanomaterials and 1 mg of palygorskite nanorods in 200 mL of deionized water, mix them uniformly with ultrasound, and filter them onto a polyethersulfone microfiltration membrane, so that the composite nanomaterials and palygorskite self-assemble to form a membrane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com