A kind of electrode sheet and its preparation method and application

An electrode sheet, aluminum foil technology, applied in circuits, capacitors, electrical components and other directions, can solve the problems of limited contact area between ruthenium oxide and electrolyte, restricting the high-frequency performance of solid aluminum capacitors, and limiting the application of ruthenium oxide's superior performance, etc. The effect of utilization and electrode performance, high energy density, high capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Product 1:

[0071] The percentages of each substance in the electrode sheet are: 60% of activated carbon, 5% of acetylene black, 10% of graphite powder, 20% of ruthenium oxide powder, and 5% of binder.

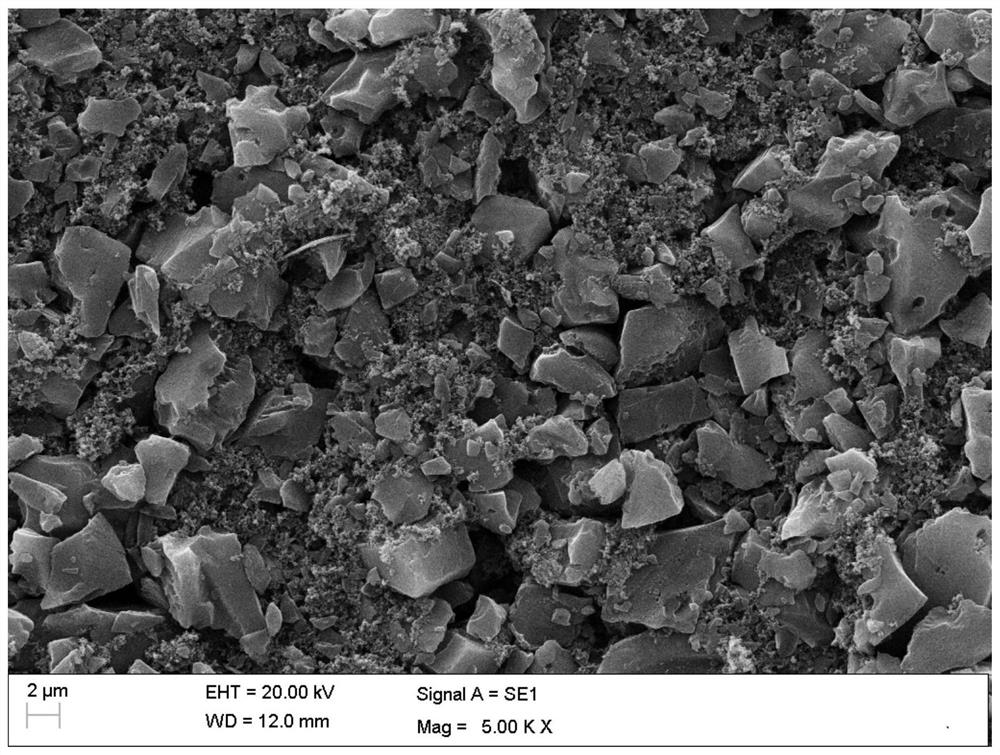

[0072] 1) Preparation of ruthenium oxide ultrafine powder:

[0073] Add ruthenium trichloride to 50% ethanol in proportion at room temperature, stir for 1 h to form a uniform solution, and add 0.2 mol / L ammonium bicarbonate dropwise to neutralize under stirring conditions, and control the pH at the end point of the titration to 7. Obtain a colloidal solution and dry it at 200° C. for 3 hours to obtain an amorphous ruthenium oxide powder with a suitable crystal water content.

[0074] 2) Preparation of composite carbon slurry:

[0075] Put the activated carbon powder into the electric drying oven, heat it at 120°C for 2 hours for drying treatment; dissolve 0.02g of the binder added by the organic solvent and continue stirring with a magnetic stirrer for 4 hours, then ...

Embodiment 2

[0107] Product 1:

[0108] The percentages of each substance in the electrode sheet are: activated carbon 75%, acetylene black 5%, graphite powder 10%, and binder 10%.

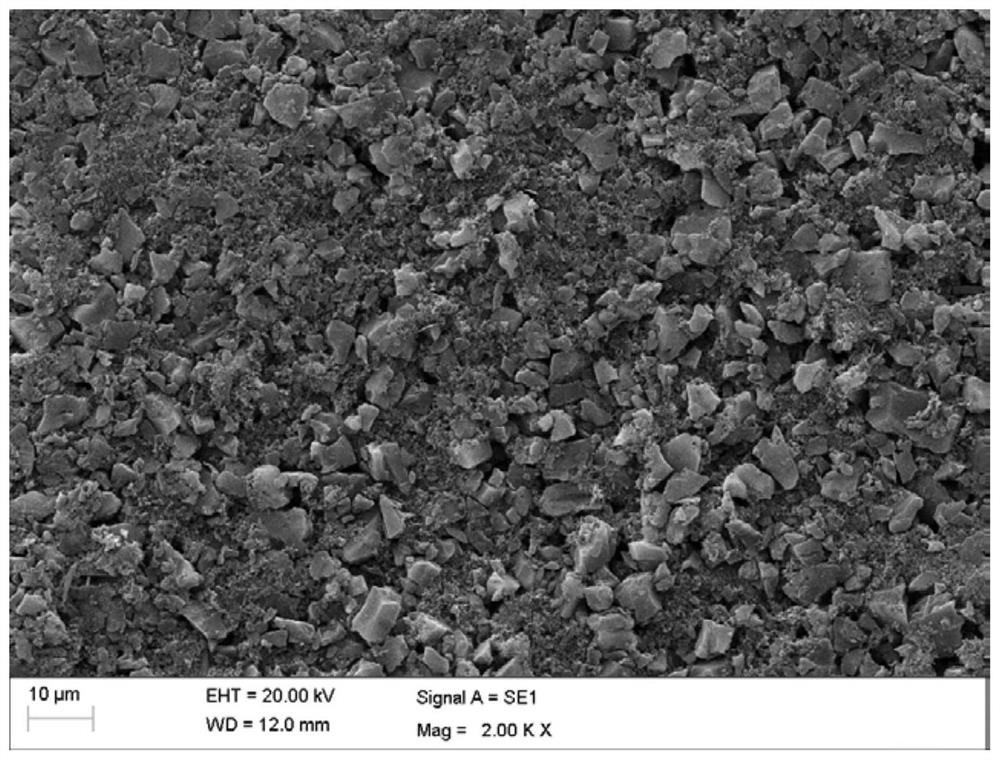

[0109] 1) ruthenium oxide precipitated aluminum foil;

[0110] The cathode foil used in the experiment is aluminum foil (light foil) (w (Al) ≥ 99.9%), the thickness is 50 μm, and the size of the aluminum foil is 10mm×50mm; after the aluminum foil is soaked in 10% NaOH solution at 60°C for 15 to 30 seconds , rinse with water, dehydrate with absolute ethanol / acetone, and dry with cold air;

[0111] Select ruthenium trichloride (RuCl3) 5mol / L, potassium chloride (KCl) 0.1mol / L and hydrochloric acid (HCl) 0.01mol / L to configure an electroplating solution with a concentration of 5mol / L and a pH value of 2.3; use three electrodes The system consists of a working electrode, an auxiliary electrode and a reference electrode to deposit ruthenium oxide on the aluminum foil. In the three-electrode system, the working el...

Embodiment 3

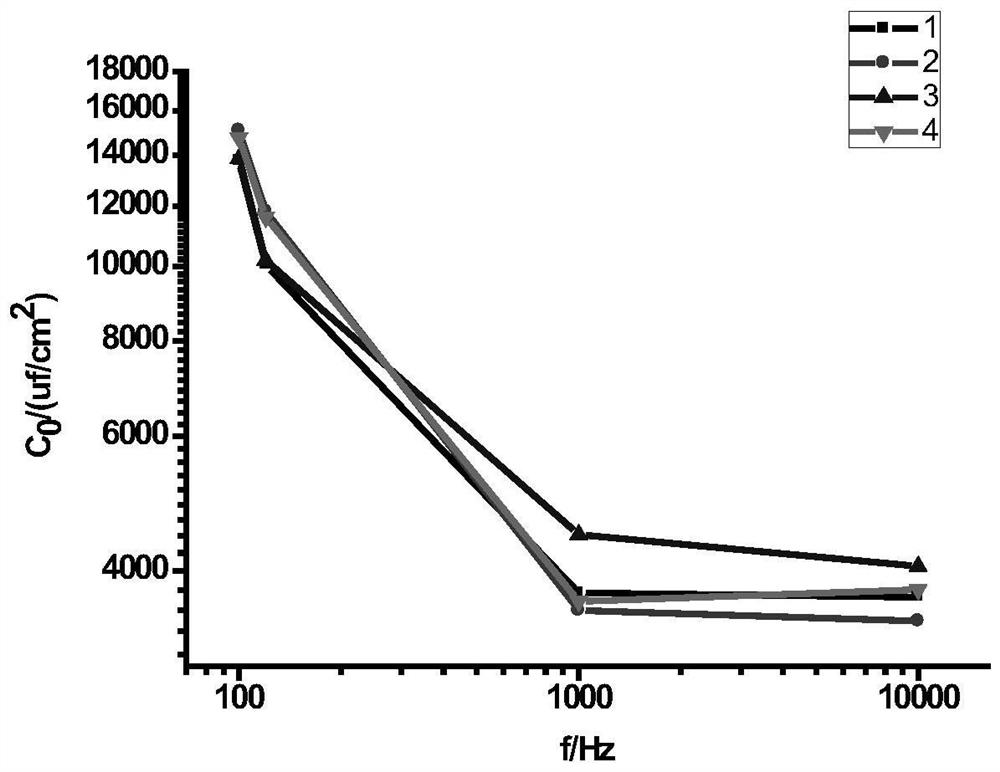

[0144] 1. Experimental materials: electrode sheets prepared under the conditions of products 1-4 in Example 1 and electrode sheets prepared under the conditions of products 1-4 in Example 2

[0145] 2. Experimental method

[0146] With Chroma LCR METER MODEL--100 type capacitor tester, the capacitance of the electrode sheet in the product 1-4 in the above-mentioned embodiment 1 and the product 1-4 in the embodiment 2 is measured;

[0147] The firmness of the carbon layer is assessed by a qualitative test using adhesive tape. Under the condition of 1kHz-0.3V, the aluminum / carbon composite foil is soaked in the measuring solution and placed for 20 days, then taken out and dried, and the electrode pieces in the products 1-4 in the embodiment 1 and the products 1-4 in the embodiment 2 are measured. The quality of the carbon layer depends on the shedding of the carbon layer, and then evaluates the firmness of the carbon layer, and calculates according to the following formula:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com