Coprinus comatus mushroom dreg porous carbon adsorbent as well as preparation method and application thereof

A technology of Coprinus comatus and Coprinus comatus, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of low carbon yield, loss of surface functional groups, corrosion, etc., and achieve high carbon yield and good industrial performance. The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention discloses a preparation method of a porous carbon adsorbent for Coprinus comatus slag, comprising:

[0026] S1, mixing Coprinus comatus scum and an activator to form a mixed slurry for hydrothermal reaction;

[0027] S2. Drying and pyrolyzing the solid obtained from the hydrothermal reaction to obtain the porous carbon adsorbent for Coprinus comatus slag.

[0028] In some embodiments of the present invention, the activator in step S1 includes at least one of ammonium phosphate, phosphoric acid, and urea.

[0029] In some embodiments of the present invention, the mass ratio of the activating agent to Coprinus comatus mushroom residue in step S1 is (2 to 4):1, for example, 2:1, 3:1, 4:1.

[0030] In some embodiments of the present invention, the reaction temperature of the hydrothermal reaction in step S1 is 100 to 180°C, such as 100°C, 110°C, 120°C, 130°C, 140°C, 150°C, 160°C, 170°C °C, 180 °C; the reaction time is 6 to 12h, such as 6h, 7h, 8h, 9h, 10h, 1...

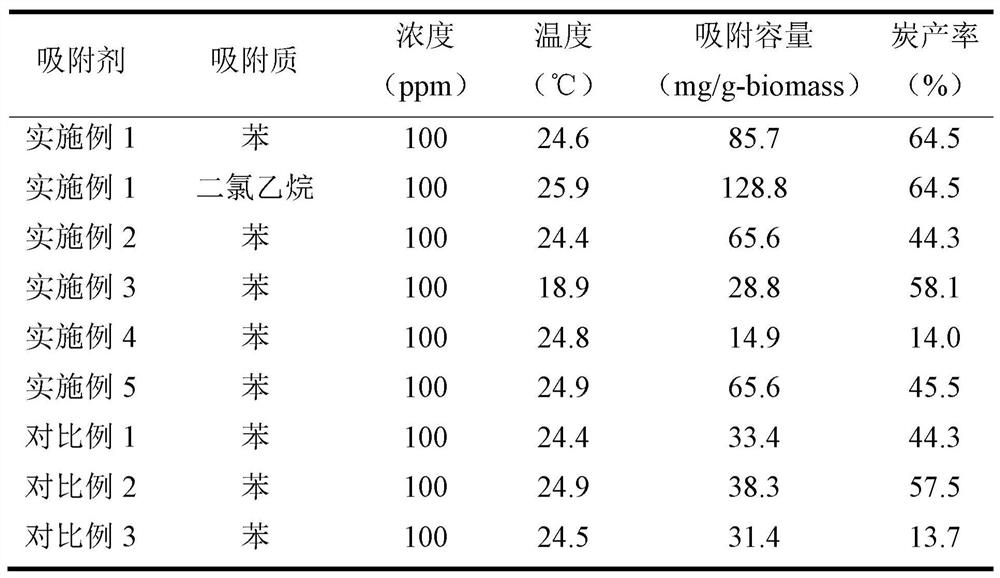

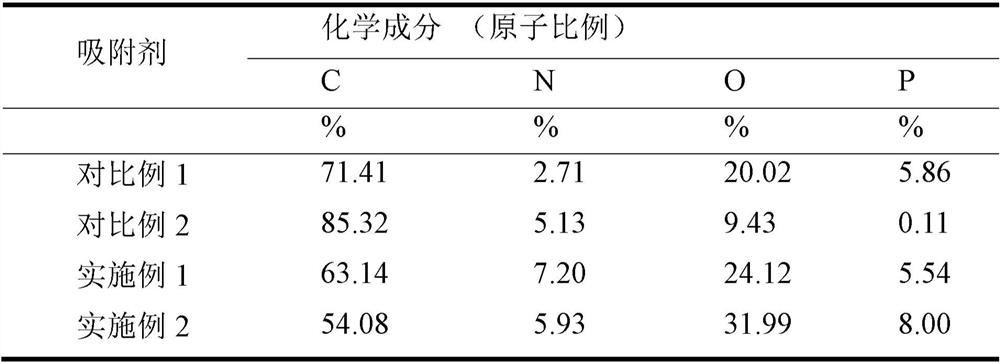

Embodiment 1

[0060] 1. Biomass raw material pretreatment

[0061] The collected Coprinus comatus fungus residues were dried in a blast drying oven at 60°C, and the dried samples were crushed to 20 meshes by a pulverizer, and classified and packed for later use.

[0062] 2. Preparation method

[0063] (1) Hydrothermal: Weigh 5.0g of Coprinus comatus mushroom residue, pour 50mL of deionized water into it, weigh 15g (NH 4 ) 3 PO 4 Pour in the above slurry, stir at RT for 1h (300r / min), transfer to a 100mL hydrothermal reaction kettle, seal, keep the temperature in a drying oven at 180°C for 6h, open it for natural cooling, and dry at 105°C.

[0064] (2) Pyrolysis: transfer to a tube furnace at 600°C, keep the temperature constant for 1h, (heating rate 5°C / min, N2 100mL / min), after natural cooling, wash with HCl to remove ash, dry at 105°C, the charcoal yield is 64.5% .

[0065] Weigh 0.080 g of Coprinus comatus slag hydrothermal pyrolysis carbon (ie Coprinus comatus slag porous carbon ad...

Embodiment 2

[0067] 1. Biomass raw material pretreatment

[0068] The collected Coprinus comatus fungus residues were dried in a blast drying oven at 60°C, and the dried samples were crushed to 20 meshes by a pulverizer, and classified and packed for later use.

[0069] 2. Preparation method

[0070] (1) Hydrothermal: Weigh 5.0g of Coprinus comatus mushroom residue, pour 50mL of deionized water, stir evenly, transfer to a 100mL hydrothermal reaction kettle, seal, keep the temperature at 180°C for 6h in a drying oven, cool it naturally, open it, weigh 15.0g (NH 4 ) 3 PO 4 Add the above slurry, stir at RT for 1h (300r / min), and dry at 105°C.

[0071] (2) Pyrolysis: transfer to a tube furnace at 600°C, hold constant temperature for 1h (heating rate 5°C / min, N2 100mL / min), after natural cooling, wash with HCl to remove ash, dry at 105°C, the charcoal yield is 54.8%.

[0072] Weigh 0.080g of Coprinus comatus slag of 40-60 mesh hydrothermal pyrolysis charcoal, and conduct adsorption test in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com