Coal chemical industry high-salinity wastewater zero discharge process

A high-salt wastewater, zero-discharge technology, applied in the improvement of process efficiency, water/sewage treatment, natural water treatment, etc., can solve problems such as scaling problems, and achieve lower production and operation costs, stable water quality, and uniform material mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

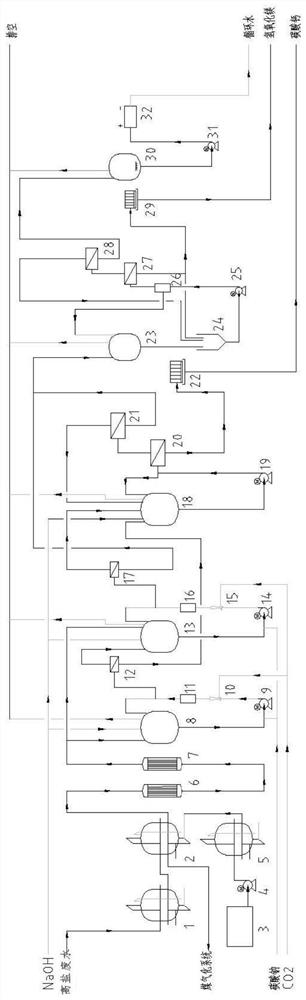

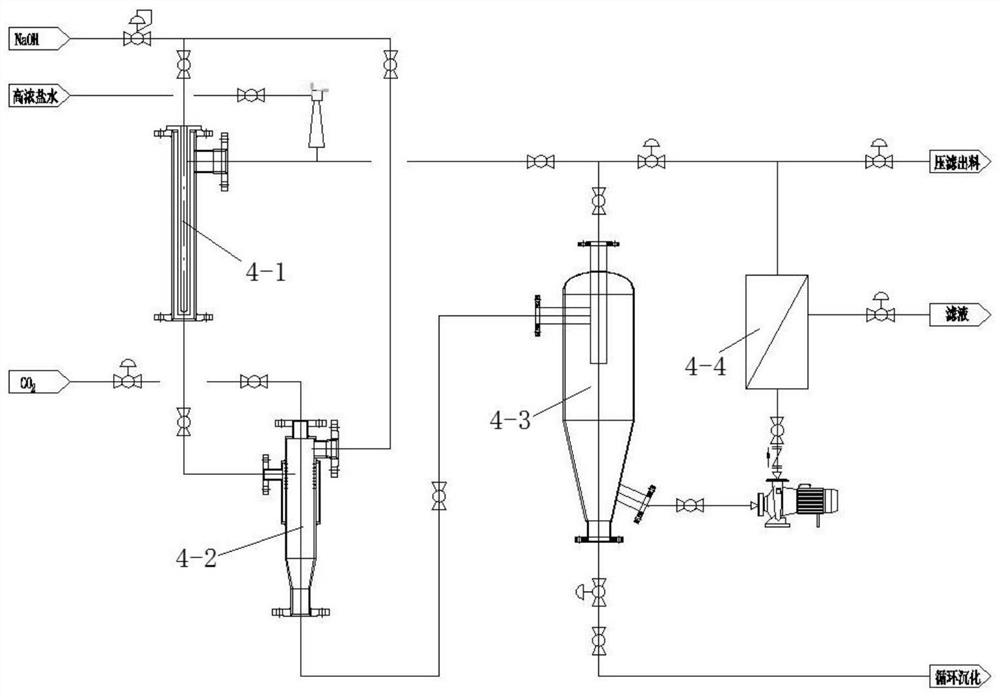

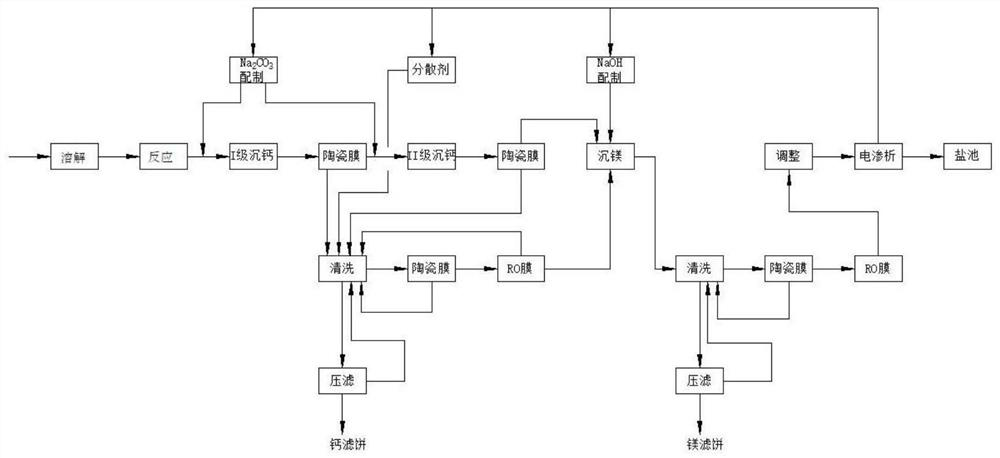

[0032] like Figure 1-2 As shown, this embodiment provides a zero-discharge process for high-salt wastewater in coal chemical industry, which is applicable to high-salt wastewater in coal chemical industry and ion exchange wastewater in various industries. It mainly treats the high-salt wastewater produced in the coal chemical industry, so that the high-salt wastewater can be reused in the coal chemical production system after treatment. After treatment, the produced water enters the adsorption tank, and after adsorption treatment, the produced water is reused in the coal chemical production system for recycling. After the adsorber is saturated, the system can be automatically cut off, and the desorption tank can analyze it to restore its working performance; the desorption tank is mainly used for the desorption of the adsorber, and the desorption waste liquid generated by it passes through the first-stage heat exchanger, The second-level heat exchanger is sent to the calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com