Method for producing cow leather gelatin by using pickled raw leather

A technology of cowhide and raw hide, which is applied to the preparation method of peptides, chemical instruments and methods, animal/human proteins, etc. It can solve the problems of easy pollution of the environment, partial dissolution of collagen, and cumbersome processes, so as to shorten the time of enzymatic hydrolysis and improve extraction. The effect of high rate and high purity of gelatin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

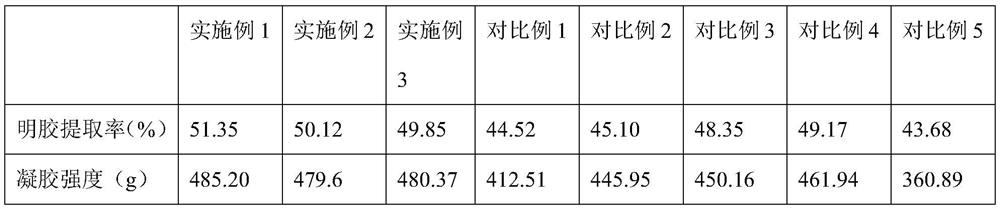

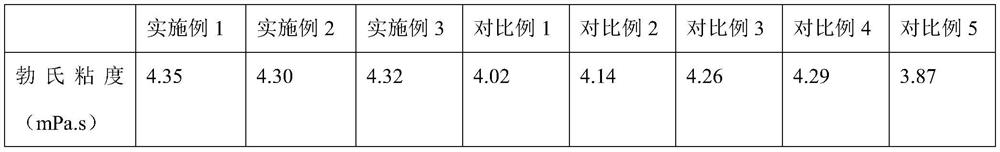

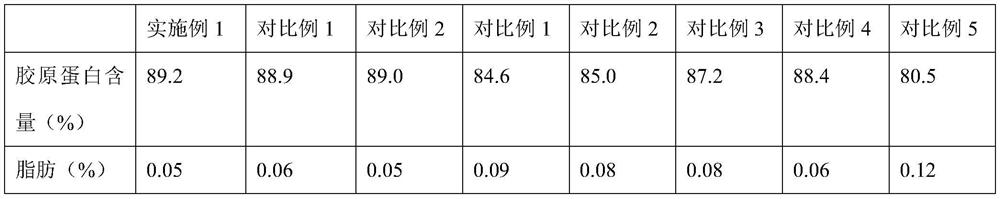

Examples

Embodiment 1

[0025] (1) Clean the surface of the raw cowhide hide after depilation, cut it into pieces, and use a degreasing agent composed of lauric acid-isopropanol-water according to the ratio of 1:5:20 to degrease for 3 hours to obtain degreased cowhide for use;

[0026] (2) Add 20 mL of gradient sodium chloride-triethanolamine aqueous solution to each 1 g of skim cowhide for stirring and soaking, each gradient soaks for 2 hours, the first gradient is 3% sodium chloride aqueous solution; the second gradient is 5.5% sodium chloride Aqueous solution; the third gradient is 8% sodium chloride aqueous solution; the mass ratio of the sodium chloride and triethanolamine is 4:1, filter after soaking, and clean the cowhide with deionized water;

[0027] (3) Add 30mL of 0.3% sodium lauryl sulfate into 30mL of processed cowhide, add 2000U / g acid protease and dioctyl sulfosuccinate sodium salt (the amount added is the The mass concentration in the solution is 0.8%), enzymatic hydrolysis at 35-38°C...

Embodiment 2

[0030] (1) Clean the surface of the cowhide raw hide after depilation, cut it into pieces, and use a degreasing agent composed of lauric acid-isopropanol-water according to the ratio of 0.8:5:20 to degrease for 3 hours to obtain degreased cowhide for use;

[0031] (2) Add 25mL of gradient sodium chloride-triethanolamine aqueous solution to each 1g of defatted cowhide for stirring and soaking, each gradient soaks for 2 hours, the first gradient is 2.5% sodium chloride aqueous solution; the second gradient is 5.5% sodium chloride Aqueous solution; the third gradient is 8.5% sodium chloride aqueous solution; the mass ratio of the sodium chloride and triethanolamine is 4:1, filter after soaking, and clean the cowhide with deionized water;

[0032] (3) Add 30mL of 0.2% sodium lauryl sulfate into 30mL of processed cowhide, add 2500U / g acid protease and dioctyl sulfosuccinate sodium salt (the amount added is The mass concentration in the liquid is 0.8%), enzymatic hydrolysis at 35-38...

Embodiment 3

[0035] (1) Clean the surface of the cowhide raw hide after depilation, cut it into pieces, and use a degreasing agent composed of lauric acid-isopropanol-water according to the ratio of 0.9:5:20 to degrease for 3 hours to obtain degreased cowhide for later use;

[0036] (2) Add 20 mL of gradient sodium chloride-triethanolamine aqueous solution to each 1 g of defatted cowhide for stirring and soaking, each gradient soaks for 2 hours, the first gradient is 3% sodium chloride aqueous solution; the second gradient is 5.0% sodium chloride Aqueous solution; the third gradient is 8.5% sodium chloride aqueous solution; the mass ratio of the sodium chloride and triethanolamine is 4:1, filter after soaking, and clean the cowhide with deionized water;

[0037] (3) Add 30mL of oxhide after every g of treatment to phosphate buffered saline solution containing 0.25% sodium lauryl sulfate, add 1800U / g acid protease and dioctyl sulfosuccinate sodium salt The mass concentration in the liquid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com