Sound-insulation and heat-preservation integrated functional material and preparation method thereof

A functional material, sound insulation and thermal insulation technology, applied in the field of sound insulation and thermal insulation materials, to achieve the effect of low thermal conductivity, high hardness and rapid curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

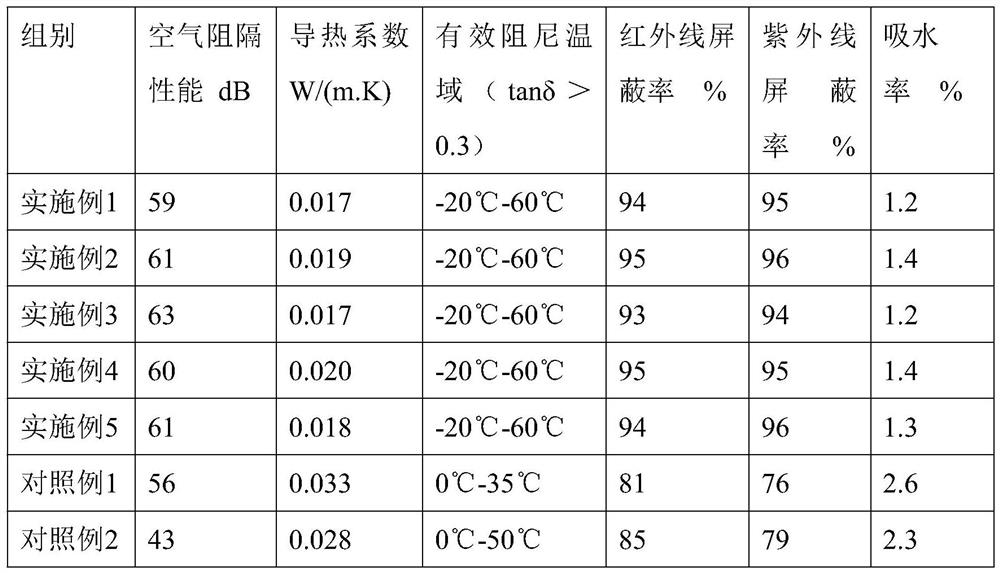

Examples

Embodiment 1

[0034] A method for preparing a sound-insulating and heat-insulating integrated functional material, comprising the following steps:

[0035] 1) Weigh raw materials according to the proportion: 20 parts of silicone resin, 6 parts of diluent, 25 parts of infrared blocking absorber, 6 parts of ultraviolet absorber, 0.2 part of dispersant, 0.2 part of defoamer, 0.4 part of leveling agent, double 4 parts of o-methylamine fluorene and 10 parts of flake graphite; the diluent is divided into three parts, and the dispersant and defoamer are divided into two parts; the infrared blocking absorber includes 14 parts of nano cesium tungstate and nano ATO 6 parts; diluent is tripropylene glycol diacrylate, ultraviolet absorber is substituted acrylonitrile, dispersant is hydrophobic modified carboxylic acid sodium salt; defoamer is silicone, leveling agent is cellulose acetate butyrate ;

[0036] 2) Preparation of nano-cesium tungstate dispersion: use a nano-grinder to blend cesium tungstat...

Embodiment 2

[0043] A method for preparing a sound-insulating and heat-insulating integrated functional material, comprising the following steps:

[0044]1) Weigh raw materials according to the proportion: 24 parts of silicone resin, 12 parts of diluent, 30 parts of infrared blocking absorbent, 12 parts of ultraviolet absorber, 0.8 part of dispersant, 0.4 part of defoamer, 0.8 part of leveling agent, double 10 parts of o-methylamine fluorene and 14 parts of flake graphite; the diluent is divided into three parts, and the dispersant and defoamer are divided into two parts; the infrared blocking absorber includes 16 parts of nano cesium tungstate and nano ATO 8 parts; the diluent is tripropylene glycol diacrylate, the ultraviolet absorber is substituted acrylonitrile, the dispersant is polyacrylic acid sodium salt; the defoamer is silicone, and the leveling agent is carboxymethylcellulose acetate propionate ;

[0045] 2) Preparation of nano-cesium tungstate dispersion: use a nano-grinder to...

Embodiment 3

[0052] A method for preparing a sound-insulating and heat-insulating integrated functional material, comprising the following steps:

[0053] 1) Weigh raw materials according to the proportion: 22 parts of silicone resin, 9 parts of diluent, 27 parts of infrared blocking absorbent, 9 parts of ultraviolet absorber, 0.5 part of dispersant, 0.3 part of defoamer, 0.6 part of leveling agent, double 7 parts of o-methylamine fluorene and 12 parts of flake graphite; the diluent is divided into three parts, and the dispersant and defoamer are divided into two parts; the infrared blocking absorber includes 15 parts of nano cesium tungstate and nano ATO 7 parts; diluent is pentaerythritol triacrylate, ultraviolet absorber is substituted acrylonitrile, dispersant is hydrophobic modified carboxylic acid sodium salt; defoamer is organosilicon, leveling agent is carboxymethyl cellulose acetate Propionate;

[0054] 2) Preparation of nano-cesium tungstate dispersion: use a nano-grinder to ble...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| UV shielding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com