Preparation method of lithium ion battery silicon monoxide negative electrode material

A lithium-ion battery, silicon oxide technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc. Effectiveness of Utilization, Improved Conductivity, and Improved Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

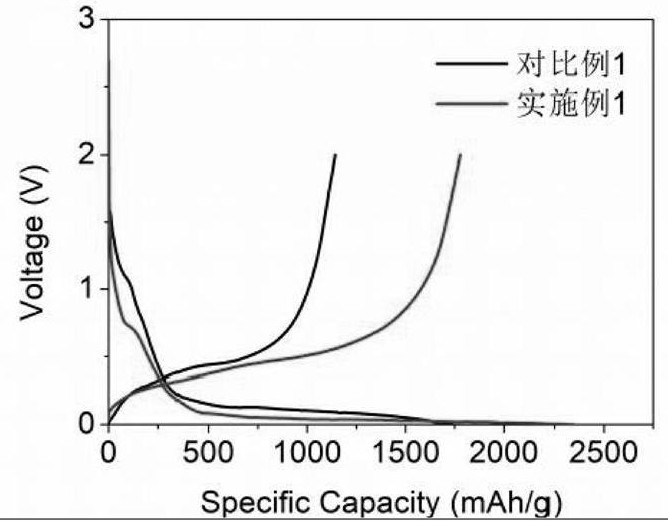

Embodiment 1

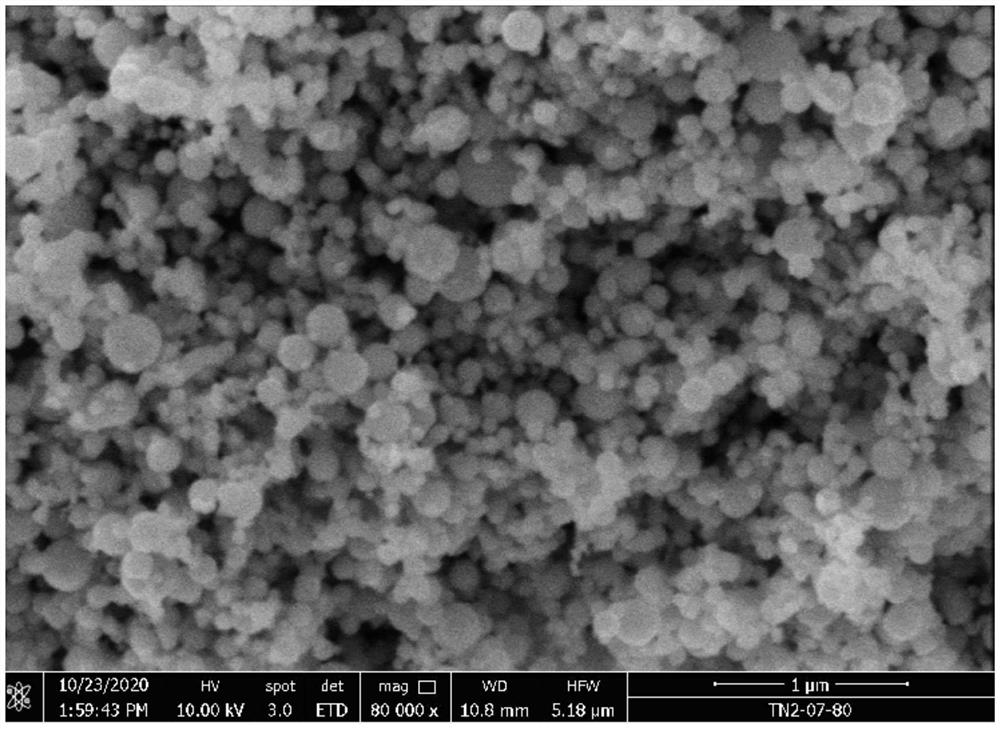

[0036] The micron SiOx with quality A is evenly added into the plasma high-temperature furnace to evaporate, and the nano-scale SiOx powder B is produced, and the dispersion liquid is collected. The D50 of the obtained nano-SiOx is 100 nm;

[0037] The quality of the above-mentioned nano-SiO dispersion liquid is mixed in the D graphene oxide absolute ethanol liquid containing C;

[0038] The above-mentioned homogeneous mixed solution is spray-dried to obtain a secondary structure of an interwoven network of graphene oxide and SiOx;

[0039] The composite material with secondary structure of E is mixed with pitch F evenly again, heated in a rotary furnace and inert gas is passed through during this process, and carbon source gas acetylene is passed through at a rate of G L / h to obtain a multi-level structure of siloxane Composite electrode material.

[0040] The above-mentioned silicon-oxygen composite electrode material is mixed with nano-conductive carbon Super P and binder ...

Embodiment 2

[0044] The micron SiOx with quality A is evenly added into the plasma high-temperature furnace to evaporate, and the nano-scale SiOx powder B is produced, and the dispersion liquid is collected. The D50 of the obtained nano-SiOx is 100 nm;

[0045] The quality of the above-mentioned nano-SiO dispersion liquid is mixed in the D graphene oxide absolute ethanol liquid containing C;

[0046]The above-mentioned homogeneous mixed solution is spray-dried to obtain a secondary structure of an interwoven network of graphene oxide and SiOx;

[0047] Mix the composite material with secondary structure of E with F sucrose evenly, heat in a rotary furnace and pass inert gas during this process and pass in carbon source gas methane at a rate of G L / h to obtain a multi-level structure of siloxy Composite electrode material.

[0048] The above-mentioned silicon-oxygen composite electrode material is mixed with nano-conductive carbon Super P and binder PVDF in a ratio of 8:1:1 in nitrogen met...

Embodiment 3

[0050] The micron SiOx with quality A is evenly added into the plasma high-temperature furnace to evaporate, and the nano-scale SiOx powder B is produced, and the dispersion liquid is collected. The D50 of the obtained nano-SiOx is 100 nm;

[0051] The quality of the above-mentioned nano-SiO dispersion liquid is mixed in the D graphene oxide absolute ethanol liquid containing C;

[0052] The above-mentioned homogeneous mixed solution is spray-dried to obtain a secondary structure of an interwoven network of graphene oxide and SiOx;

[0053] The composite material with secondary structure of E is mixed with polydopamine F again, heated in a rotary furnace and an inert gas is introduced into the carbon source gas acetylene at a rate of G L / h during this process to obtain a multi-level structure of silicon oxide based composite electrode materials.

[0054] The above-mentioned silicon-oxygen composite electrode material is mixed with nano-conductive carbon Super P and binder PVD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com