Preparation method of tantalum oxide/tantalum carbide composite material as well as product and application thereof

A composite material, tantalum carbide technology, used in electrochemical generators, structural parts, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] At room temperature, acetylacetone and ethanol were sequentially added to the reactor at a volume ratio of 1:4, and the total volume of the two was 60% of the reactor volume; at a stirring rate of 900 rpm, TaCl was sequentially added at a mass ratio of 1:0.2 5 With phenolic resin (H + ), TaCl 5 The mass ratio with ethanol is 1:40, and the mixed solution is obtained by stirring evenly, and the temperature of the mixed solution is raised to 60° C., kept at reflux for 3 hours, and the complex is obtained;

[0034] The above complex was placed in a 50mL reactor, and solvothermally reacted at 200°C for 3h, cooled to room temperature, centrifuged, washed, and dried at 80°C to obtain a precursor powder containing tantalum source and carbon source;

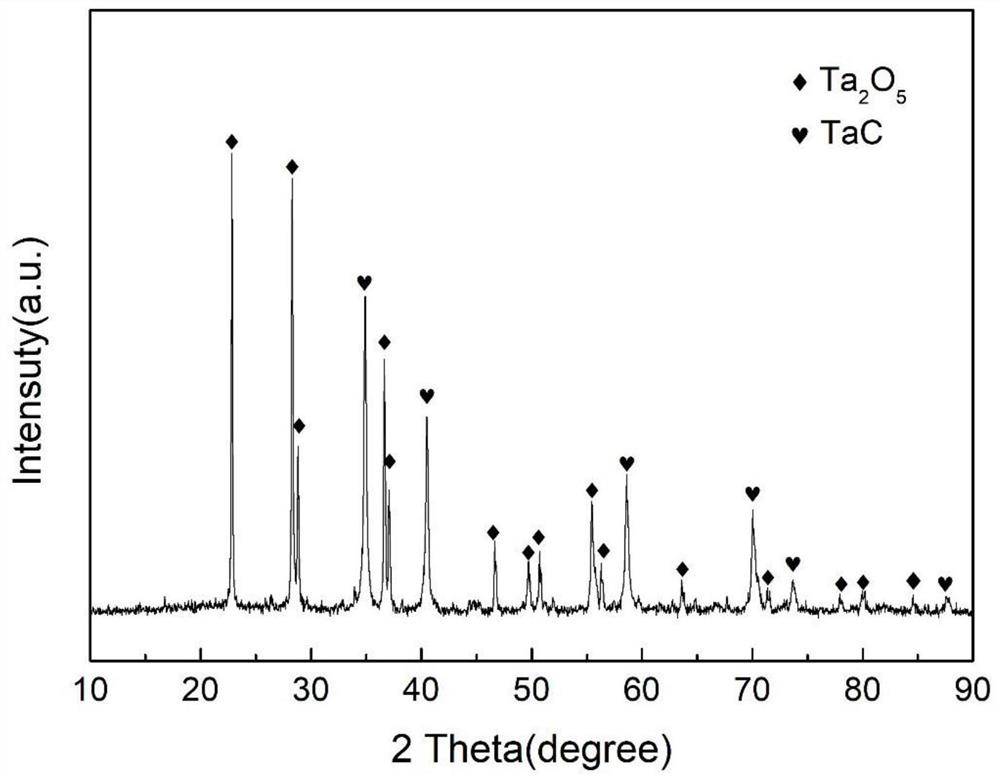

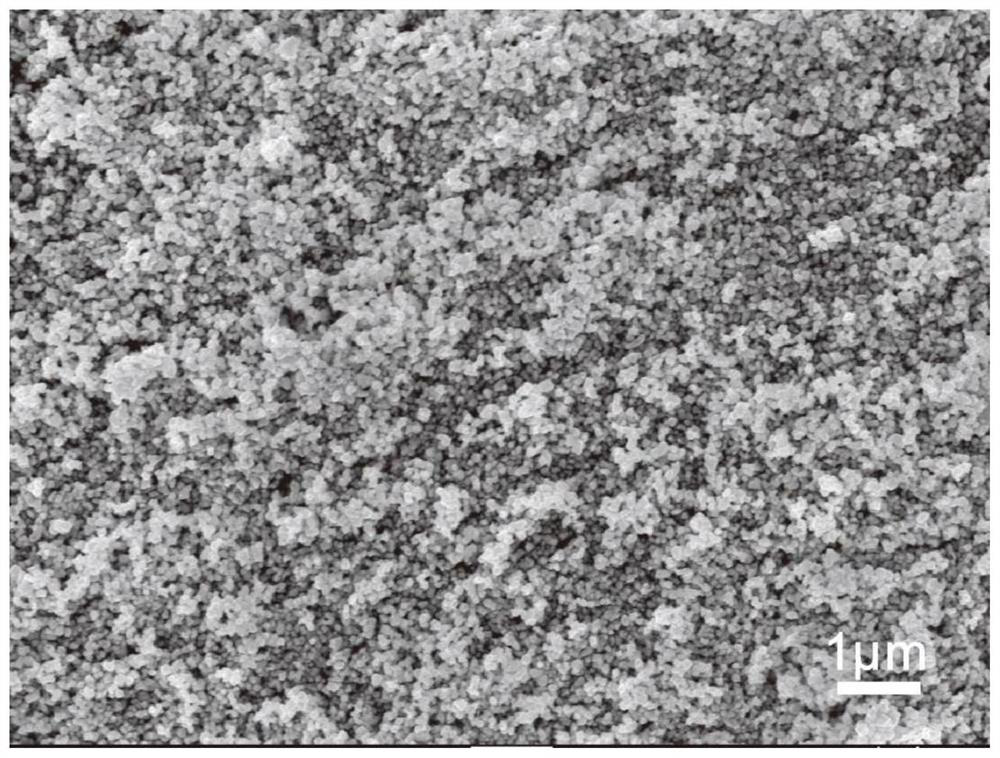

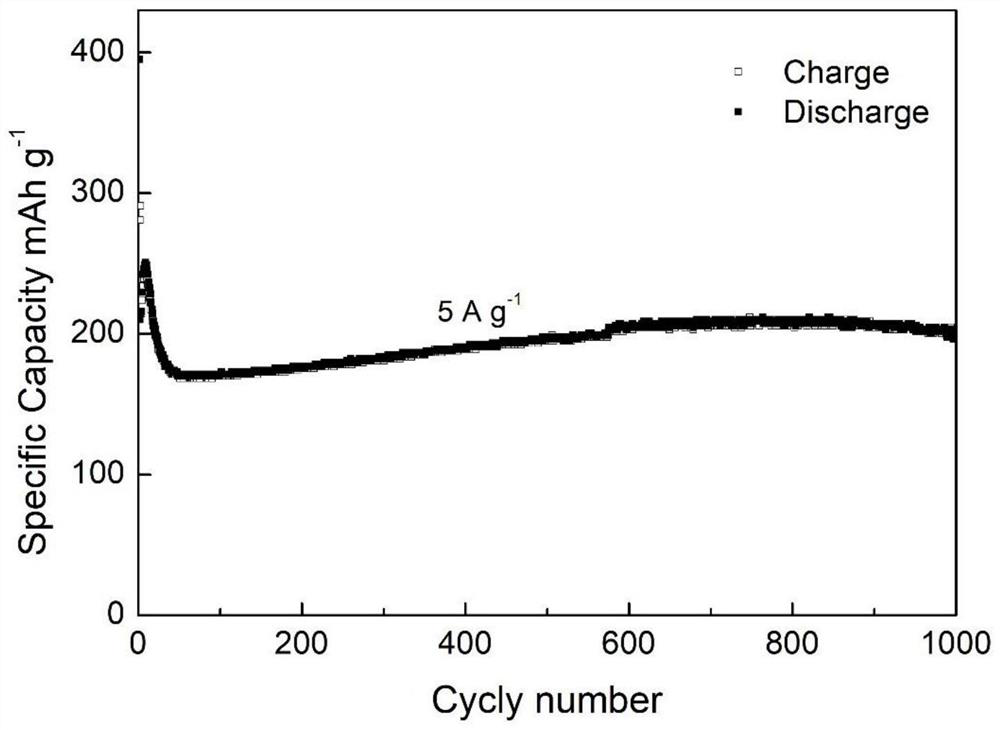

[0035] The precursor powder is fully ground and placed in a tube furnace, under the protection of argon, the temperature is raised to 1200°C at 20°C / min for high-temperature heat treatment, kept for 1h, and cooled with the furnace...

Embodiment 2

[0038] At room temperature, acetylacetone and n-butanol were sequentially added to the reactor at a volume ratio of 1:4, and the total volume of the two was 60% of the reactor volume; at a stirring rate of 800 rpm, sequentially added acetylacetone and n-butanol at a mass ratio of 1:0.1 TaCl 5 With phenolic resin (H + ), TaCl 5 The mass ratio to n-butanol is 1:10, and the mixed solution is obtained by stirring evenly, and the mixed solution is heated to 60° C., kept at reflux for 1 hour, and the complex is obtained;

[0039] The above complex was placed in a 50mL reactor, and subjected to solvothermal reaction at 160°C for 9h, cooled to room temperature, centrifuged, washed, and dried at 80°C to obtain a precursor powder containing tantalum source and carbon source;

[0040] The precursor powder is fully ground and placed in a tube furnace. Under the protection of argon, the temperature is raised to 1100°C at 10°C / min for high-temperature heat treatment, kept for 1h, and cool...

Embodiment 3

[0042] At room temperature, acetylacetone and isopropanol were sequentially added to the reactor at a volume ratio of 1:4, and the total volume of the two was 60% of the reactor volume; at a stirring rate of 500 rpm, sequentially added acetylacetone and isopropanol at a mass ratio of 1:0.15 TaCl 5 With phenolic resin (H + ), TaCl 5 The mass ratio to isopropanol is 1:10, and the mixed solution is obtained by stirring evenly, and the mixed solution is heated to 60° C., kept at reflux for 2 hours, and the complex is obtained;

[0043] The above complex was placed in a 50mL reactor, and subjected to solvothermal reaction at 180°C for 6h, cooled to room temperature, centrifuged, washed, and dried at 80°C to obtain a precursor powder containing tantalum source and carbon source;

[0044] The precursor powder is fully ground and placed in a tube furnace. Under the protection of argon, the temperature is raised to 1400°C at 20°C / min for high-temperature heat treatment, kept for 0.5h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com