Antibacterial elastic composite medical dressing and preparation method thereof

A medical and elastic technology, which is applied in the fields of medical formula, medical science, non-woven fabrics, etc., can solve the problems of unfavorable wound adhesion, low elongation at break, uneven thickness, etc., and achieve isolation of bacterial infection, high strength, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

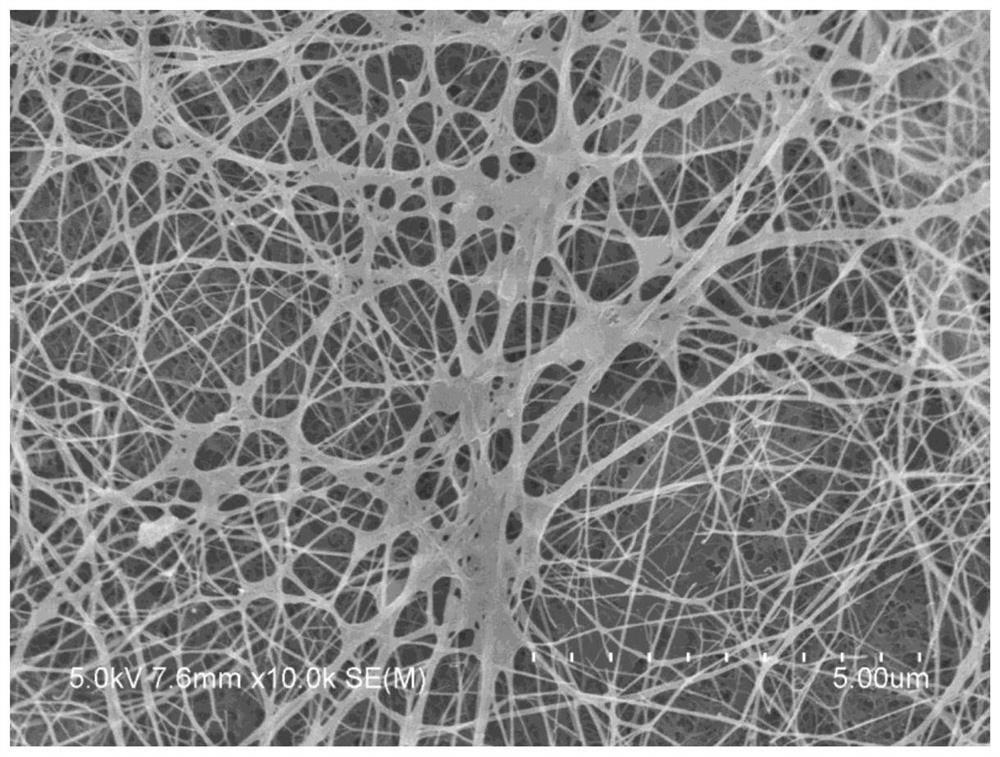

[0039] 1. Accurately weigh 2.88g of polyurethane (PU) masterbatch, 0.72g of polycaprolactone (PCL) and 0.036g of TiO 2Nanoparticles, be dissolved in 16.4g N, in the N-dimethylformamide (DMF), stir with magnetic stirrer at room temperature until polyurethane and polycaprolactone dissolve completely, obtain the uniform and stable solute mass fraction of 18%. spinning solution. The above spinning solution was used for electrospinning. Set the electrospinning process parameters as follows: the distance between the spinneret and the receiving plate is 15cm, the flow rate of the spinning solution is 1.2ml / h, the applied voltage is 18kV, and the aluminum foil is received for 20h to obtain PU / PCL / TiO 2 Composite nanofiber membrane.

[0040] 2. Use Acetobacter xylinum as the strain for cultivating bacterial cellulose membranes, accurately weigh 3g of tryptone, 5g of yeast powder and 25g of mannitol, distill the volume to 1L with distilled water and pack them in each Erlenmeyer flask,...

Embodiment 2

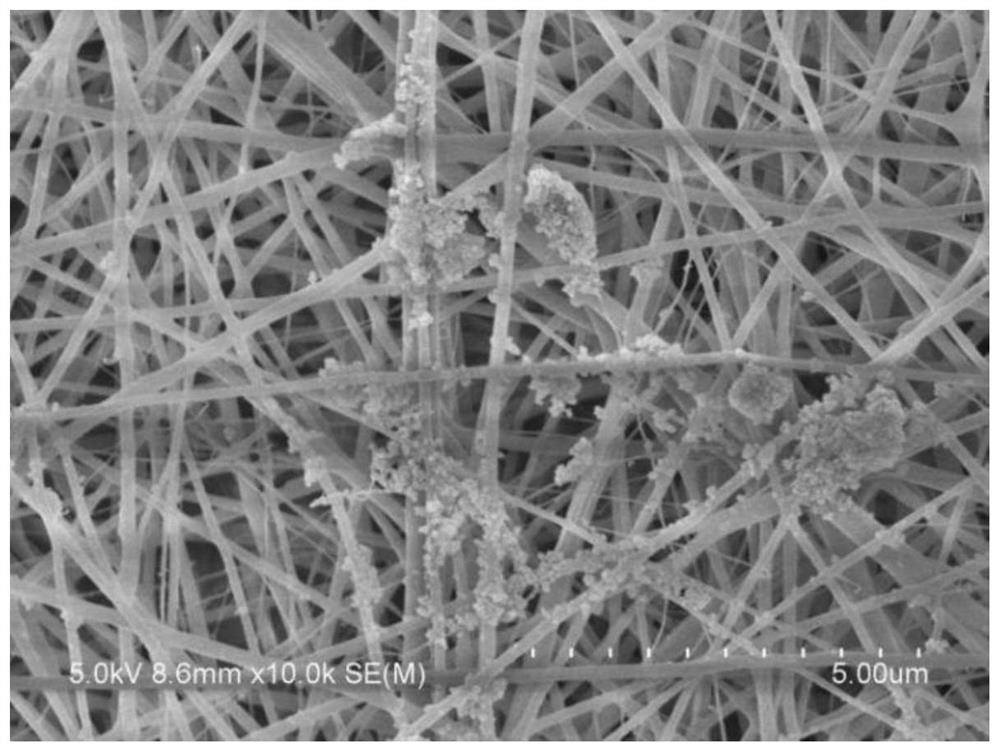

[0045] 1. Accurately weigh 2.8g of polyurethane (PU) masterbatch, 1.2g of polycaprolactone (PCL) and 0.2g of TiO 2 Nanoparticles, dissolved in 16g of N, N-dimethylformamide (DMF), stirred with a magnetic stirrer at room temperature until the polyurethane and polycaprolactone were completely dissolved to obtain a uniform and stable spinning with a mass fraction of 20%. liquid. The above spinning solution was used for electrospinning. Set the electrospinning process parameters as follows: the distance between the spinneret and the receiving plate is 20cm, the flow rate of the spinning solution is 0.8ml / h, the applied voltage is 20kV, and the aluminum foil is received for 16h to obtain PU / PCL / TiO 2 Composite nanofiber membrane.

[0046] 2. Acetobacter xylinum was used as the strain for culturing the bacterial cellulose membrane, and 1.5 g of tryptone, 2.5 g of yeast powder and 12.5 g of mannitol were accurately weighed, and dissolved in 1 L of distilled water to obtain a bacter...

Embodiment 3

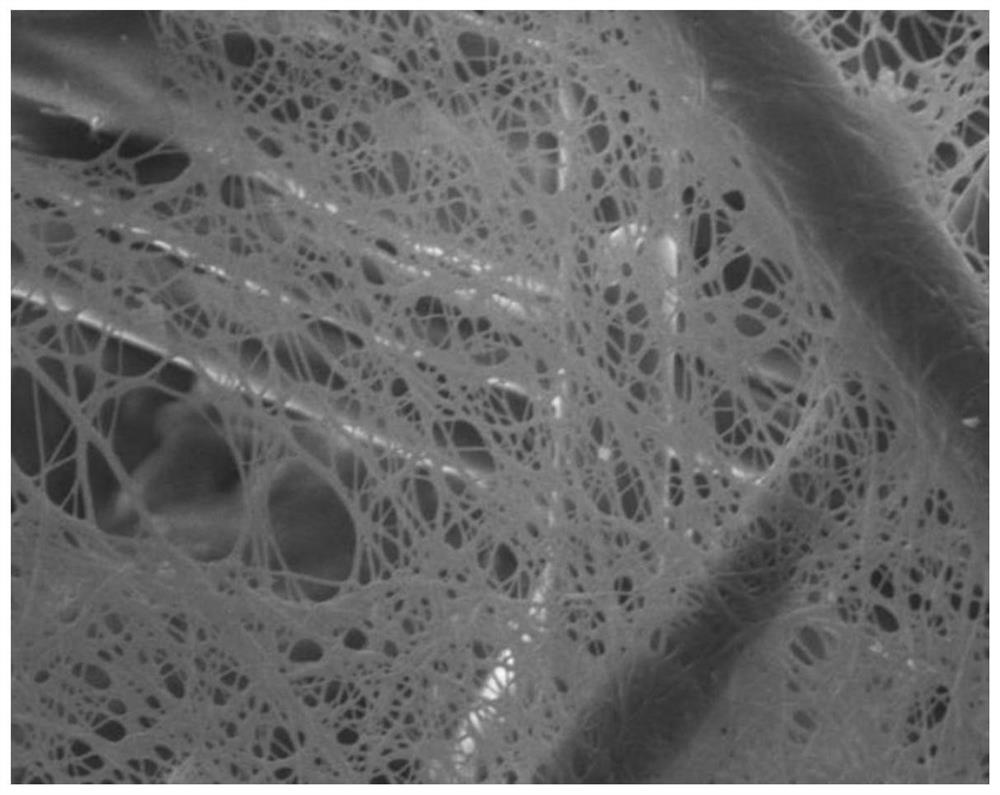

[0051] 1. Accurately weigh 3.42g of polyurethane (PU) masterbatch, 0.38g of polycaprolactone (PCL) and 0.266g of TiO 2 Nanoparticles, dissolved in 16.2g N, N-dimethylformamide (DMF), stirred with a magnetic stirrer at room temperature until the polyurethane and polycaprolactone were completely dissolved to obtain a uniform and stable spinning with a mass fraction of 19%. silk liquid. The above spinning solution was used for electrospinning. Set the electrospinning process parameters as follows: the distance between the spinneret and the receiving plate is 18cm, the flow rate of the spinning solution is 0.6ml / h, the applied voltage is 18kV, and the aluminum foil is received for 12h to obtain PU / PCL / TiO 2 Composite nanofiber membrane.

[0052] 2. Acetobacter xylinum was used as the strain for culturing the bacterial cellulose membrane, and 1.5 g of tryptone, 2.5 g of yeast powder and 12.5 g of mannitol were accurately weighed, and dissolved in 1 L of distilled water to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com