Method for producing tagatose from bionic silicon mineralized micro-capsule immobilized multienzyme

A technology of biomimetic silicon and tagatose, applied in the direction of immobilized enzymes, biochemical equipment and methods, immobilized on or in inorganic carriers, etc., can solve the problems of high cost of protamine, unsuitable for industrial scale production, etc., and achieve Mild conditions, simple process, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

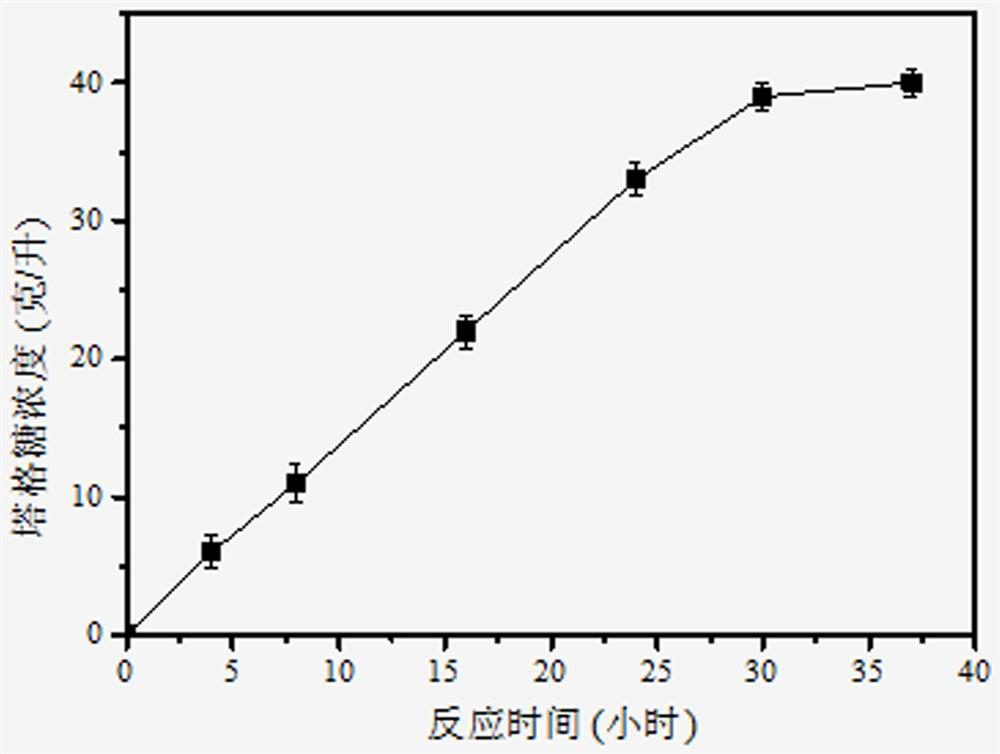

Embodiment 1

[0037] The biomimetic silicon mineralized microcapsule immobilized multi-enzyme of this example was prepared by the following method:

[0038] (1) Five main enzyme molecules involved in the production of tagatose: glucan phosphorylase, glucose phosphomutase, glucose phosphate isomerase, 6-phosphate tagatose 4-position epimerase and 6 Phosphotagatose phosphatase is pre-mixed according to the specific enzyme dosage, wherein the dosage of glucan phosphorylase is 0.1 mg / ml, the dosage of glucose phosphomutase is 0.1 mg / ml, the dosage of glucose phosphoisomerase The dosage of tagatose-6-phosphate 4-position epimerase was 0.2 mg / ml, and the dosage of tagatose-6-phosphate phosphatase was 0.2 mg / ml. Add the above-mentioned enzyme solution into the calcium chloride solution with a concentration of 0.33 M, and pour an equal molar concentration and equal volume of sodium carbonate solution into the calcium chloride solution at a speed of 700 r / min, react for 20-30 s, and Centrifuge at 3...

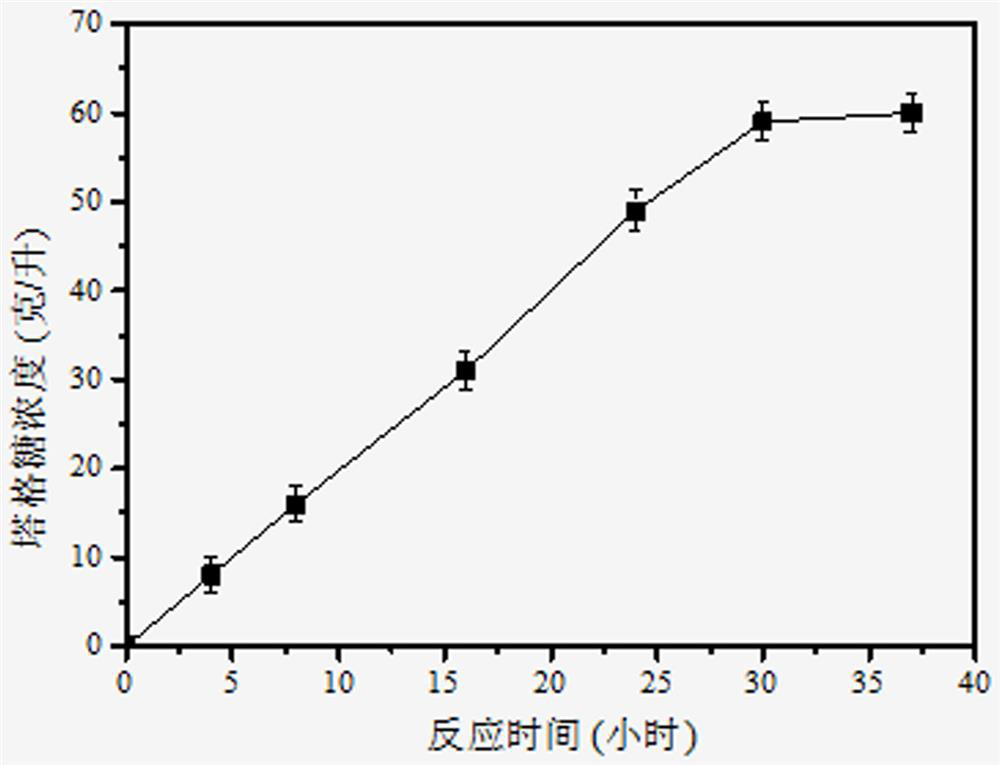

Embodiment 2

[0043] Compared with Example 1, the biomimetic silicon mineralization microcapsules immobilized multi-enzymes in this example differ only in that the number of layers of the biomimetic silicon mineralization microcapsules is changed from 1 layer to 2 layers. That is, the step (2) and step (3) of Example 1 are repeated twice, that is, after the calcium carbonate microspheres containing enzymes that are obtained in the step (2) of Example 1, the capsule wall layer is 1 layer, and then According to the mass ratio of 30:1, the polyethylenimine solution was uniformly mixed with the obtained calcium carbonate microspheres containing enzymes with one capsule wall layer for 10-20 minutes; centrifuged at a speed of 3000 r / min, After removing the supernatant, wash with deionized water until the supernatant does not contain polyethyleneimine; according to the mass ratio of 30:1, add the sodium silicate solution to the above microspheres and mix evenly for 10-20 min; at 3000 r Centrifuge ...

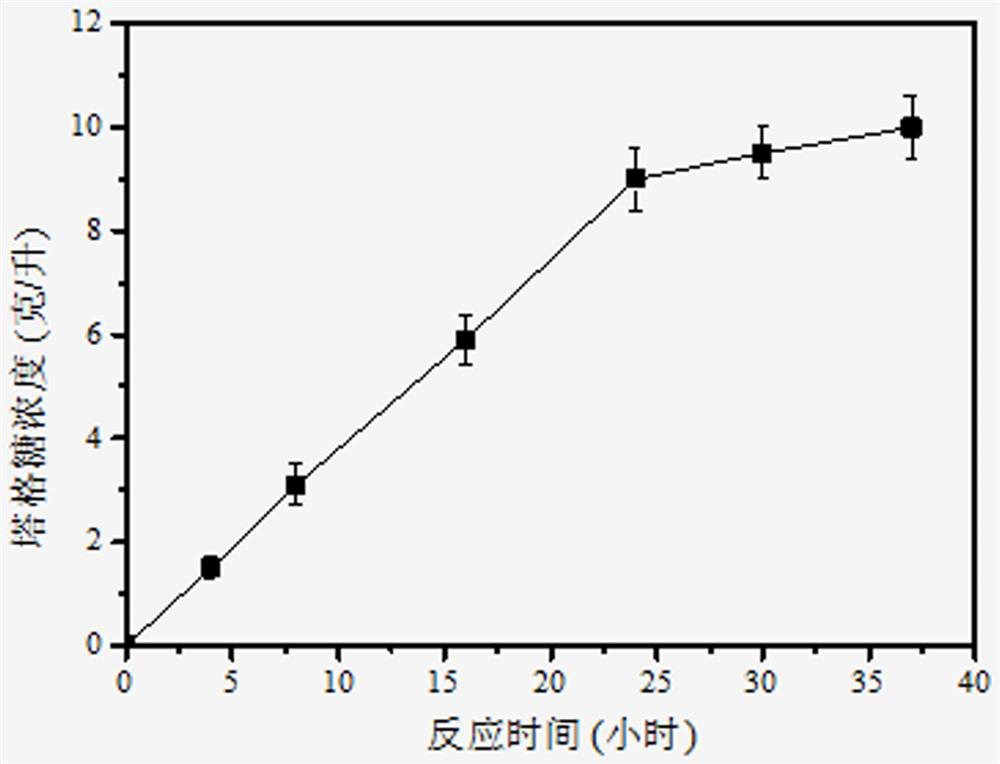

Embodiment 3

[0045] Compared with Example 1, the biomimetic silicon mineralization microcapsule immobilized multi-enzyme in this example differs only in that the number of layers of the wall of the biomimetic silicon mineralization microcapsule changes from 1 to 3 layers. That is, step (2) and step (3) of Example 1 are repeated 3 times, that is, the number of cyst wall layers obtained by repeating step (2) and step (3) in Example 2 is 2 layers of enzyme-containing After the calcium carbonate microspheres, finally according to the mass ratio of 30:1, the polyethyleneimine solution and the calcium carbonate microspheres containing the enzyme were uniformly mixed for 10-20 min; centrifuged at 3000 r / min to remove the above Wash the clear liquid with deionized water until the clear liquid does not contain polyethyleneimine; according to the mass ratio of 30:1, add the sodium silicate solution to the above microspheres and mix evenly for 10-20 min; at 3000 r / min Centrifuge at a high speed, remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com