Roller for continuous induction type rapid quenching furnace and manufacturing method of roller

A manufacturing method, inductive technology, applied to other manufacturing equipment/tools, turbines, engine components, etc., can solve the problem of extending the working cycle, not involving the chemical composition of molybdenum rollers, physical properties and preparation methods of size specifications, lack of molybdenum and Molybdenum alloy roller physical properties and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

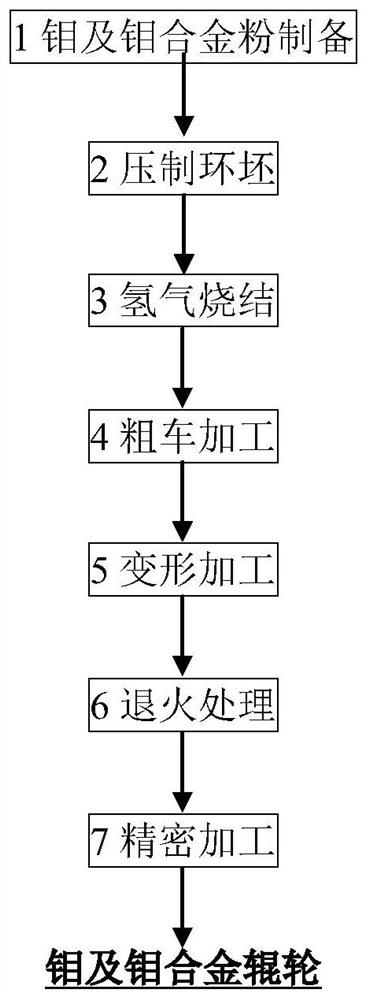

Method used

Image

Examples

preparation example Construction

[0042] (1) Preparation of molybdenum or molybdenum alloy powder: the present invention adopts 2.5-5.0 μm medium particle specification high-purity molybdenum powder or 0.5-5.0 μm medium-fine particle specification REO rare earth oxide doped molybdenum alloy powder as raw material, wherein by Molybdenum powder obtained by hydrometallurgical high purification has a Mo content of not less than 99.9% by weight, low C / O (≤50 / 500ppm) and K / W (≤20 / 50ppm) impurity content, or liquid-liquid, solid-liquid REO is uniformly doped by the method, the REO content is 0.01% by weight to 5.0% by weight, and the REO is selected from Y 2 o 3 、Sc 2 o 3 , La 2 o 3 、Ce 2 o 3 、Nd 2 o 3 、Sm 2 o 3 、Gd 2 o 3 and ZrO 2 Among them, molybdenum alloy powder uniformly doped with REO is used as raw material, which can provide better protection for the toughening and high temperature resistance of molybdenum rollers.

[0043] (2) Compressed ring billet: cold isostatic pressing is used for pressin...

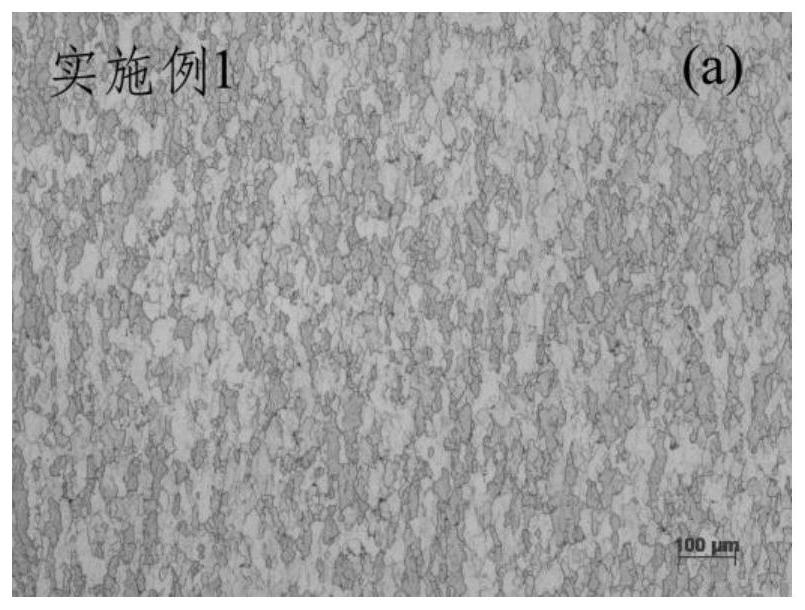

Embodiment 1

[0050] To achieve Nd via liquid-liquid method 2 o 3 Uniformly doped 1.2μm fine-grain molybdenum alloy powder is used as raw material, and its Nd 2 o 3 The content is 0.5% by weight; the Nd 2 o 3 Evenly doped molybdenum alloy powder is evenly loaded into the soft rubber sleeve with high-quality carbon steel as the rigid mandrel. When loading the material, it must be beaten evenly with a pestle and tightly sealed with iron wires. Cold isostatic pressing under 350MPa pressure for 5 minutes to obtain the shape More regular Nd 2 o 3 Doped molybdenum alloy annular compact; place the single REO-doped molybdenum alloy annular compact in a medium-frequency induction heating resistance furnace, supplemented by high-temperature-resistant high-purity ceramic particles with high sphericity as the sintering pad to minimize the ring Friction between the billet and the contact surface, sintering at 1800°C for 4 hours in a high-purity hydrogen atmosphere with a dew point of -50°C, to obt...

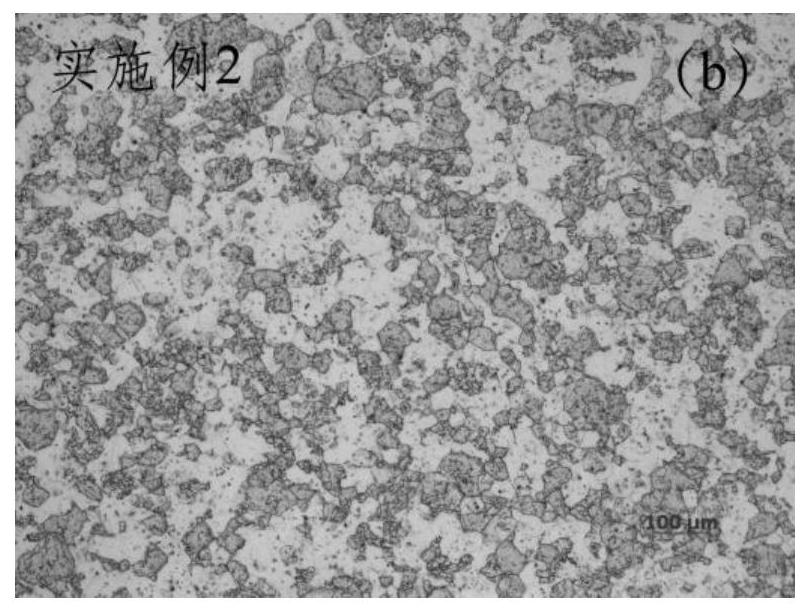

Embodiment 2

[0052] Using the 4.0μm medium particle size molybdenum powder highly purified by hydrometallurgy as raw material, the Mo content is 99.99% by weight, the impurity C / O is 50ppm / 500ppm, and the K / W is 20ppm / 50ppm respectively; the high-purity molybdenum powder Evenly put it into the soft rubber sleeve with ordinary carbon steel as the rigid mandrel. When loading, it must be pounded evenly and tightly sealed with iron wires. Cold isostatic pressing under 250MPa pressure for 20 minutes to obtain a molybdenum ring with a relatively regular shape. The molybdenum annular compact is placed in a high-temperature tungsten wire mesh resistance heating furnace, supplemented by high-temperature-resistant high-purity ceramic particles with a high degree of sphericity as a sintering pad to minimize the friction between the ring blank and the contact surface. Sintering at a high temperature of 1900°C for 8 hours in a high-purity hydrogen atmosphere with a dew point of -60°C to obtain a pure mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com