Preparation method and application of nano-chain structure array

A nano-chain and micro-nano structure technology is applied in the field of preparation of nano-chain structure arrays, which can solve the problems of unsuitability for large-scale manufacturing of metal nano-structure arrays, limited local field enhancement effect, and expensive equipment, etc. Plasmonic effect, expanded application and industrialization prospects, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

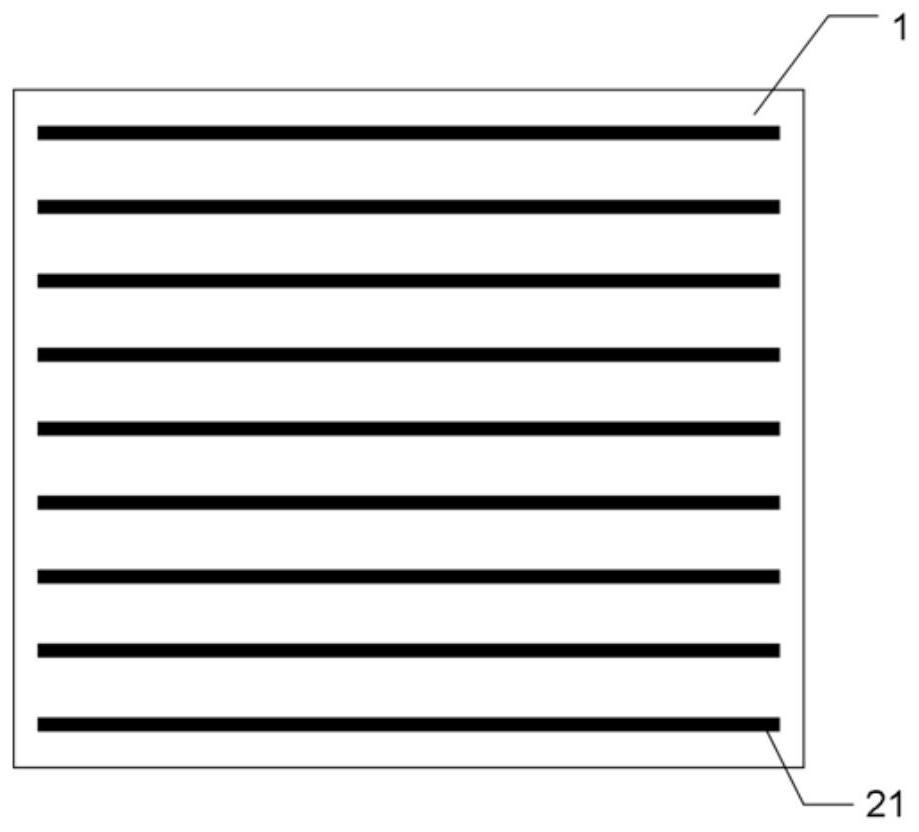

[0032] A photoresist layer with an array of striped hollow structures is prepared by wet etching:

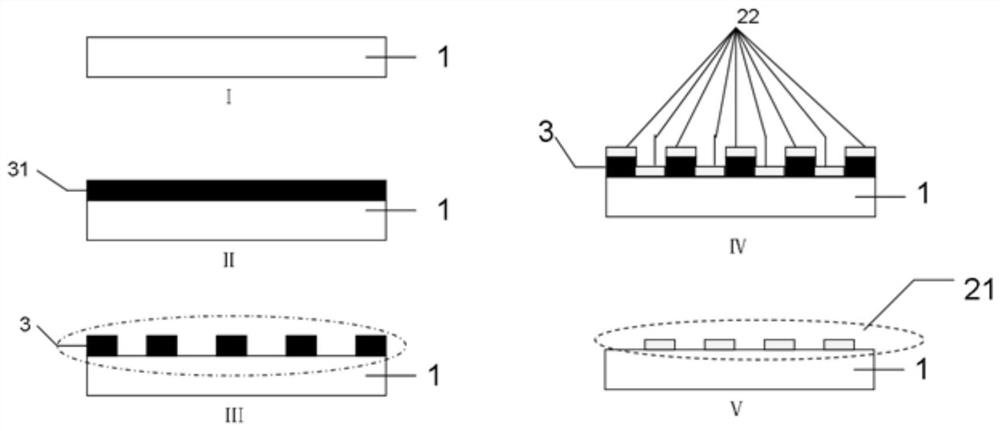

[0033] First, substrate 1, such as glass or conductive glass or silicon wafer, is thoroughly cleaned by detergents such as acetone, isopropanol, etc., to remove impurity ions (such as Figure 3-I );

[0034] Then spin-coat one deck positive photoresist film 31 (such as Figure 3-Ⅱ ), the thickness of the photoresist film is more than 200nm, after drying, a mask plate with a two-dimensional striped micro-nano structure array pattern is used for exposure, after exposure, post-baking and development are carried out, so that strips with strips are obtained on the surface of the substrate 1 The photoresist layer 3 of the hollow structure array (such as Figure 3-Ⅲ), the exposure process is to copy the pattern in the mask plate to the photoresist film 31.

[0035] In the above process, if the photoresist that is spin-coated is a positive photoresist, then the micro-nano structure a...

Embodiment 2

[0038] Preparation of strip-shaped hollow gold nanoarrays on the surface of the substrate:

[0039] The whole sample of the substrate 1 with the photoresist layer 3 of the strip-shaped hollow structure array in Example 1 is transferred to the thermal evaporation coating chamber, and the side with the photoresist layer 3 faces the evaporation source; the evaporation source material is selected For gold, the distance between the overall sample and the evaporation source is about 45cm, and the air in the thermal evaporation coating chamber is extracted to reduce the air pressure to 10 -4 Pascal; by heating the evaporation source, the evaporation material gold is converted into gold vapor and attached to the sample surface with a relatively low temperature (that is, there is gold on the substrate of the hollowed out area and the surface of the photoresist layer), and the deposition rate is 0.1nm / s, forming a layer of gold nanofilm 22 (such as Figure 3-Ⅳ );

[0040] Then the ab...

Embodiment 3

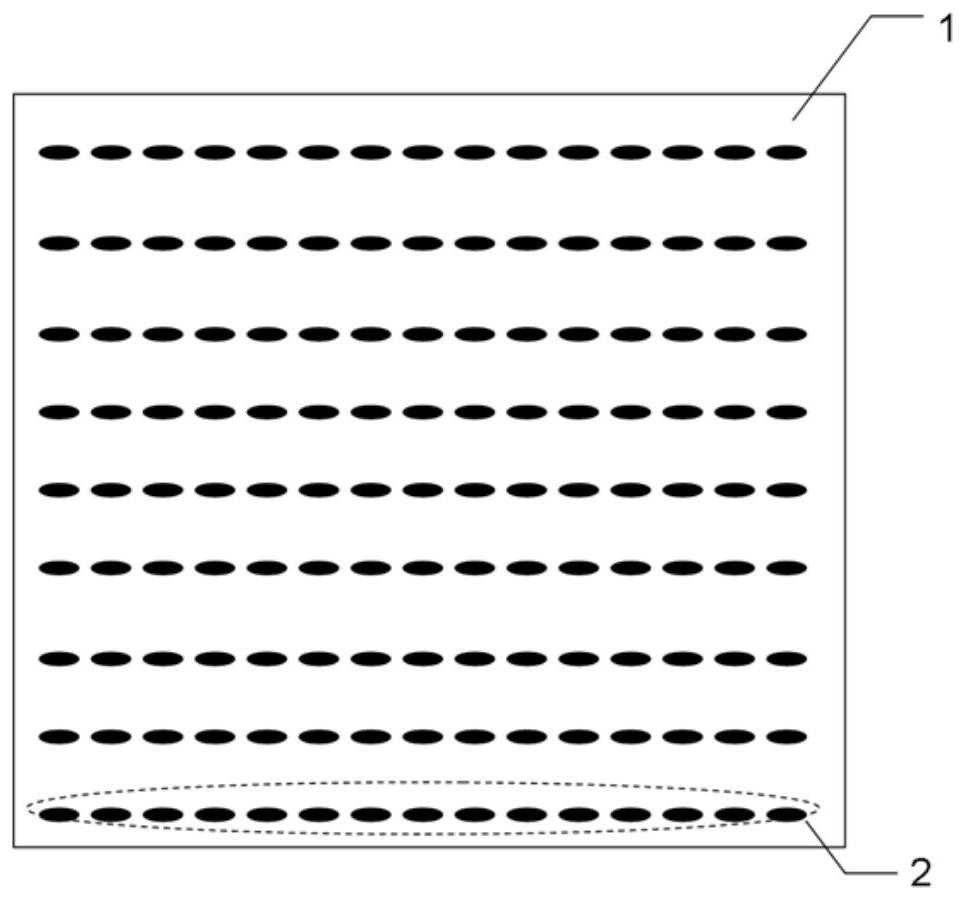

[0042] Preparation of nanochain structure arrays composed of gold nanoparticles as basic units:

[0043] Put the whole sample that has obtained the strip-shaped hollow gold nanoarray 21 on the surface of the substrate 1 through Example 2 into the annealing furnace (before putting into the annealing furnace, use a nitrogen gun to purge the sample several times to ensure that no dust is deposited on the sample. substrate), the vacuum degree of the annealing furnace was evacuated to 1×10 -2 Then, flow nitrogen gas into it, maintain normal pressure, heat the temperature in the furnace evenly to 450°C within 15 minutes by gradually heating, and keep it warm for 1 hour. After the heating, continue to flow nitrogen gas and cool it to room temperature. After completion, the annealing furnace was opened to remove the sample. The material is heated through the principle of relatively low melting point of nanomaterials in the annealing process, and then the surface tension of the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com