High-performance iron-doped nickel- or cobalt-based amorphous oxyhydroxide catalyst prepared by room temperature method, and research thereof on high-efficiency hydrogen production by electrolyzing water

A catalyst and amorphous technology, applied in the field of preparing high-performance iron-doped nickel or cobalt-based amorphous oxyhydroxide catalysts at room temperature and its high-efficiency electrolysis of water to produce hydrogen, can solve the problem of cobalt-based materials with insufficient oxygen evolution activity Improvement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

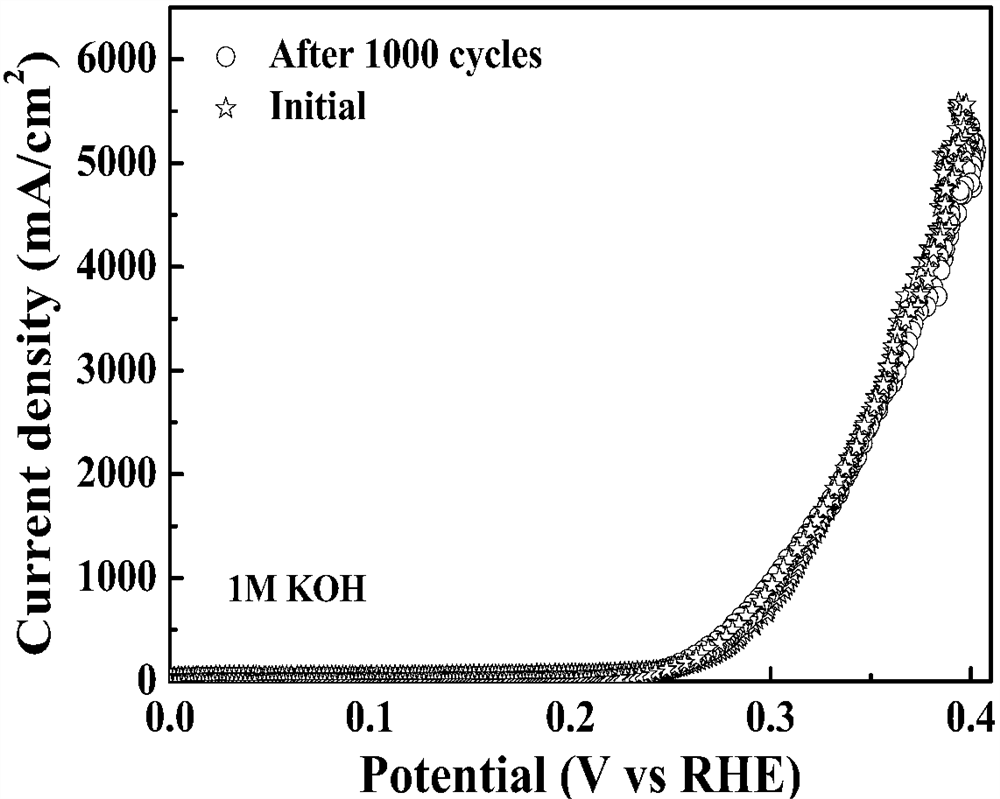

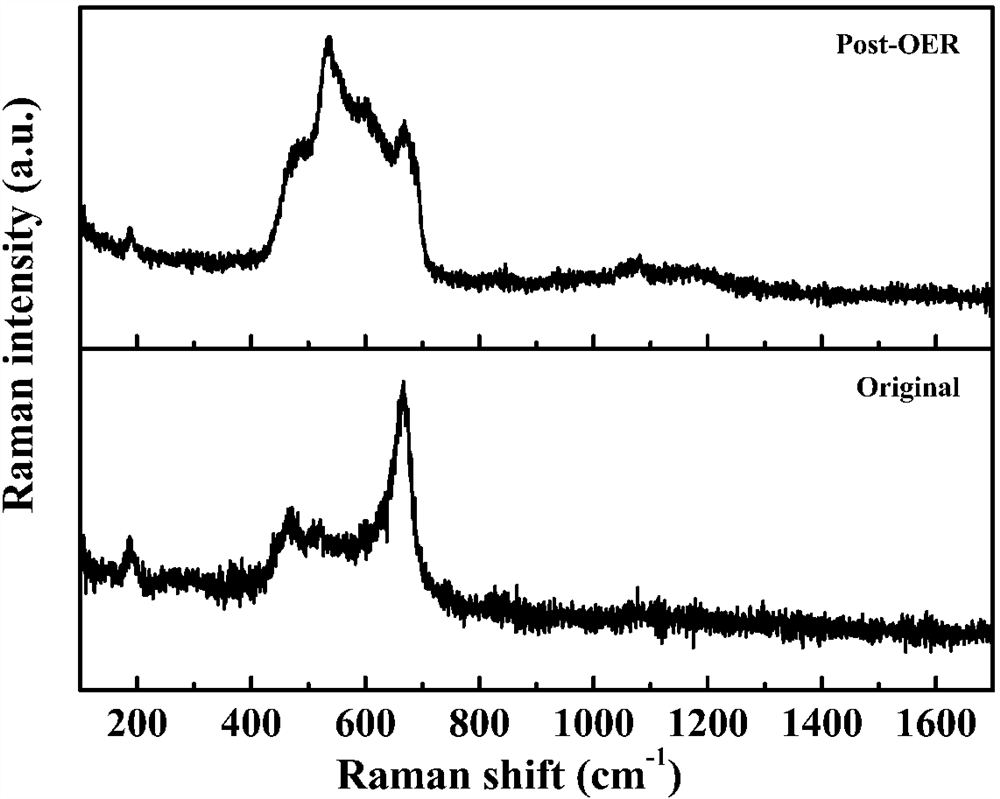

[0024] Example 1 Preparation of amorphous FeOOH / M-OOH nanosheet array and electrochemical test of oxygen evolution performance in 1 M KOH environment.

[0025] Step 1: Prepare the precursor of amorphous (oxyhydroxide) oxide, the method is as follows, the ratio of substrate liquid is 0.755 gFeCl 3 ·6H 2 O was fully dissolved in 5 ml of ethanol, ultrasonicated at a certain temperature for a certain period of time, and then the foam substrate cut out in step 1 was soaked in the substrate solution for a period of time to obtain a catalyst with high oxygen evolution electrolysis performance.

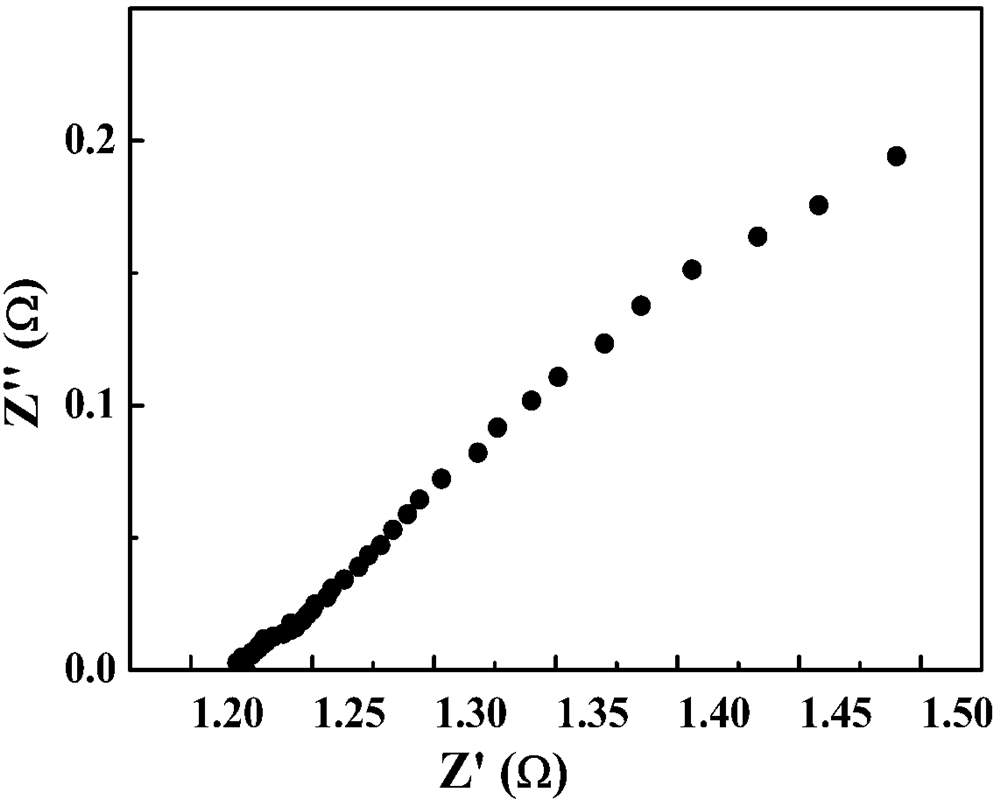

[0026]Electrocatalytic oxygen evolution performance chemical testing device GAMRY Reference 3000 electrochemical workstation, a well-known American brand, adopts a standard three-electrode system for testing. Among them, the three-electrode system has amorphous FeOOH / CoOOH as the working electrode, the Hg / HgO electrode imported by Gamry manufacturer as the reference electrode, platinum wire ...

Embodiment 2

[0027] Example 2 Preparation of amorphous FeOOH / M-OOH nanosheet arrays at different concentrations of corrosive agents and application of electrochemical tests for oxygen evolution performance in 1 M KOH electrolyte environment.

[0028] Step 1: Prepare the precursor of amorphous (oxyhydroxide) oxide. The method is as follows, and the ratio of different concentrations of substrate liquid: 0.755 g, 0.5 g, 0.25 g FeCl 3 ·6H 2 O is fully dissolved in 5 ml ethanol, and ultrasonically mixed for a period of time under heating conditions to obtain a corrosion substrate, and then the foam substrate cut in step 1 is soaked in the corrosion substrate solution for a period of time to obtain a high oxygen evolution Catalyst with electrolytic water performance.

[0029] Electrocatalytic oxygen evolution performance chemical testing device GAMRY Reference 3000 electrochemical workstation, a well-known American brand, adopts a standard three-electrode system for testing. The three-electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com