Architectural decoration coating with good flame retardance and preparation method thereof

A technology for architectural decoration and flame retardancy, which is applied in the field of architectural decorative coatings with good flame retardancy and their preparation, and can solve the problems affecting the performance and service life of architectural decorative coatings, poor flame retardant performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

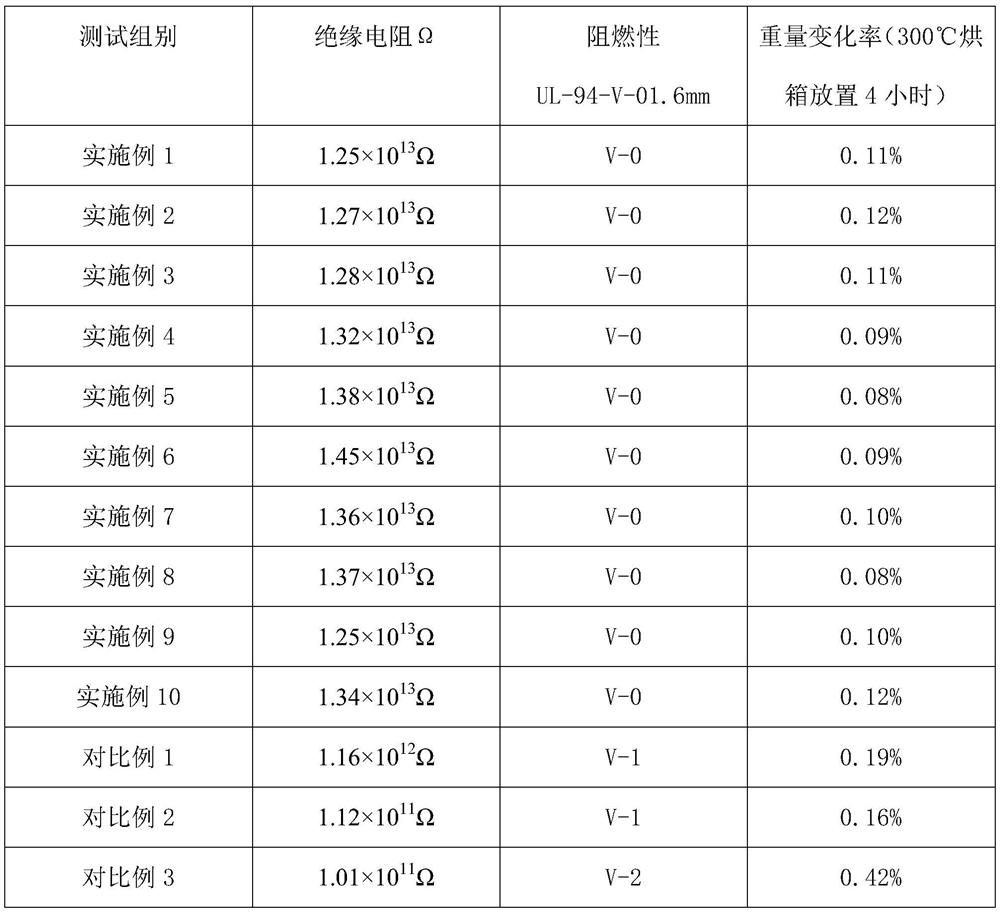

Examples

Embodiment 1

[0024] Take 45 parts of emulsion base, 4 parts of ethylene glycol, 1 part of sodium polyacrylate, 3 parts of tributyl phosphate, 2 parts of hydroxyethyl cellulose, 0.5 parts of titanium dioxide, 0.3 parts of talc, 0.5 parts of perlite, 3 parts of whipping agent, 0.3 part of lecithin, 0.1 part of terpineol, 6 parts of pigment are mixed and stirred, and described emulsion base material is pure acrylic emulsion, obtains the first mixture, for subsequent use, wherein mixing mixer speed is 650rpm, stirring time 25 minutes; add 6 parts of lauryl methacrylate, 7 parts of high-impact polystyrene, 0.8 parts of antistatic agent, and 2 parts of flame retardant into the first mixture obtained by mixing and stir again to obtain the second mixture , Standby, the flame retardant is red phosphorus and dendritic organic montmorillonite, the organic montmorillonite uses hexachlorocyclotriphosphazene as the nucleus through the Michael addition reaction of ethylenediamine and methyl acrylate to sy...

Embodiment 2

[0026] Take 48 parts of emulsion base material, 6 parts of ethylene glycol, 2 parts of sodium polyacrylate, 5 parts of tributyl phosphate, 3 parts of hydroxyethyl cellulose, 0.7 parts of titanium dioxide, 0.4 parts of talc powder, 0.7 parts of perlite, 4 parts of foaming agent, 0.5 part of lecithin, 0.2 part of terpineol, and 7 parts of pigment are mixed and stirred to obtain the first mixture, and for subsequent use, the emulsion base material is styrene-acrylic emulsion, wherein the speed of the mixing mixer is 660rpm, and the stirring time 27 minutes; add 7 parts of lauryl methacrylate, 8 parts of high-impact polystyrene, 1 part of antistatic agent, and 3 parts of flame retardant into the first mixture obtained by mixing and stir again to obtain the second mixture , for standby, the flame retardant is red phosphorus and dendritic organic montmorillonite, and the organic montmorillonite uses hexachlorocyclotriphosphazene as the core through the Michael addition reaction of et...

Embodiment 3

[0028] Take 55 parts of emulsion base, 8 parts of ethylene glycol, 3 parts of sodium polyacrylate, 7 parts of tributyl phosphate, 4 parts of hydroxyethyl cellulose, 0.8 parts of titanium dioxide, 0.5 parts of talc, 1 part of perlite, 5 parts of foaming agent, 0.7 part of lecithin, 0.3 part of terpineol, and 8 parts of pigment are mixed and stirred to obtain the first mixture. 29 minutes; add 8 parts of lauryl methacrylate, 10 parts of high-impact polystyrene, 1.2 parts of antistatic agent, and 4 parts of flame retardant into the first mixture obtained by mixing and stir again to obtain the second mixture , for standby, the flame retardant is red phosphorus and dendritic organic montmorillonite, and the organic montmorillonite uses hexachlorocyclotriphosphazene as the core through the Michael addition reaction of ethylenediamine and methyl acrylate to synthesize phosphorus-containing Nitrogen dendritic polymer, and carry out organic modification by methacryloyloxyethyltrimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com