A monoclinic structure fe 2 (moo 4 ) 3 Nanowire and its preparation method and application

A nanowire, a single technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of reduced battery area/volume energy density, decreased cycle life, increased battery internal resistance, etc. magnifying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

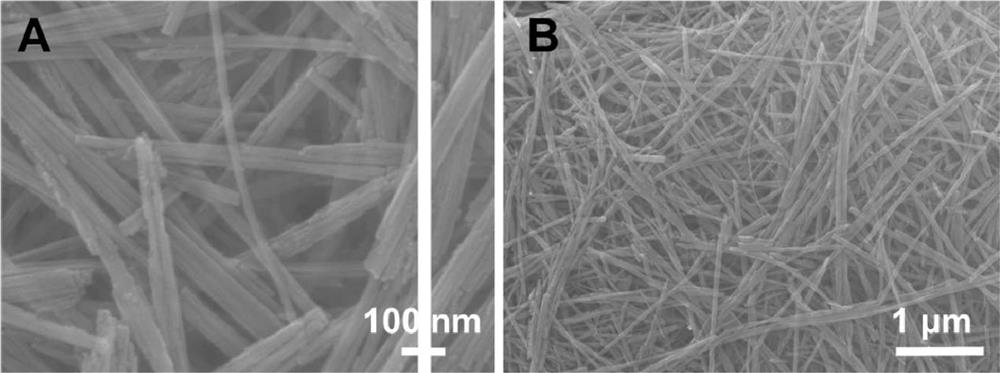

[0029] A monoclinic structure Fe disclosed in this embodiment 2 (MoO 4 ) 3 The preparation method of nanowires includes the following steps.

[0030] 1), put 0.5387 g ferric nitrate nonahydrate (Fe(NO 3 ) 3 ·9H 2 O) with 2 mL of nitric acid (HNO) 3) was dissolved in 20 mL of ultrapure water, mixed and stirred to obtain a clear and transparent solution.

[0031] 2), weigh 0.3530 g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, n Fe :n Mo =2:3) were dissolved in 20 mL of ultrapure water and stirred evenly to obtain a clear, colorless solution.

[0032] 3) Add the ferric nitrate nonahydrate solution obtained in step 1) into the ammonium molybdate solution obtained in step 2), and stir for 5 h to obtain a clear brown-yellow solution.

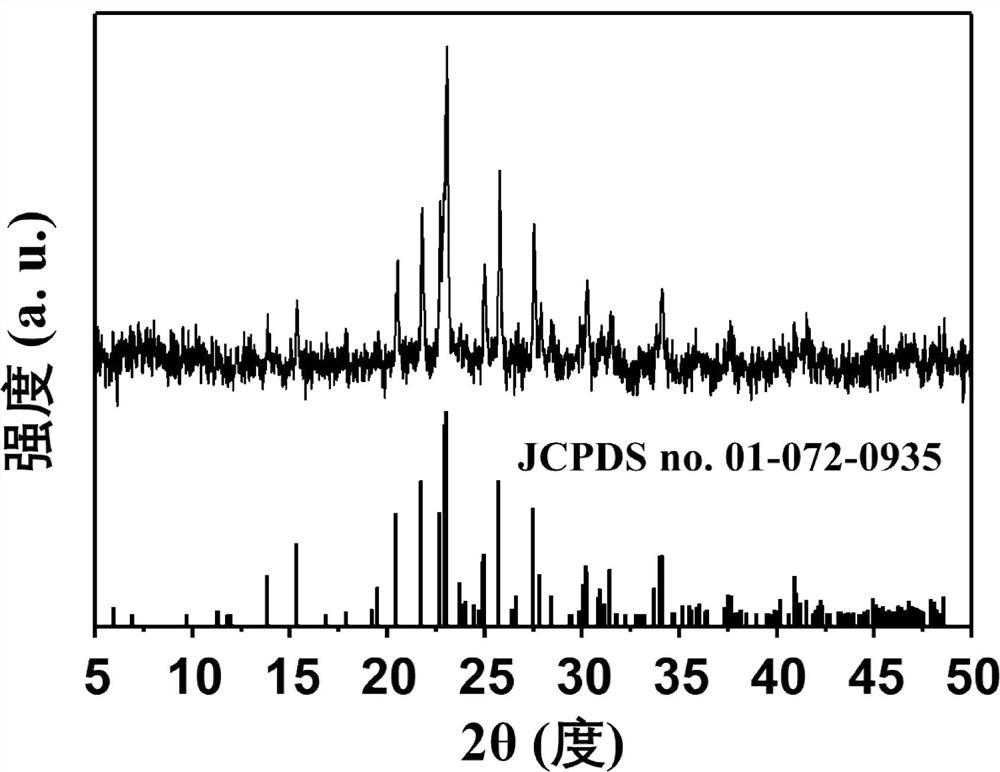

[0033] 4), put the precursor solution obtained in step 3) into a polytetrafluoroethylene reactor, conduct a hydrothermal reaction at 160 °C for 48 h, wash the hydrothermal product, and dry to obtain a yellow-green precurs...

Embodiment 2

[0043] A monoclinic structure Fe disclosed in this embodiment 2 (MoO 4 ) 3 The preparation method of the nanowire includes the following steps.

[0044] 1), 0.5387 g ferric nitrate nonahydrate ((Fe(NO 3 ) 3 9H 2 O) with 1 mL nitric acid (HNO 3 ) was dissolved in 20 mL of ultrapure water, mixed and stirred to obtain a clear and transparent solution.

[0045] 2), weigh 0.3530 g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, n Fe :n Mo =2:3) were dissolved in 20 mL of ultrapure water and stirred evenly to obtain a clear, colorless solution.

[0046] 3) Add the ferric nitrate nonahydrate solution obtained in step 1) into the ammonium molybdate solution obtained in step 2), and stir for 5 h to obtain a clear brown-yellow solution.

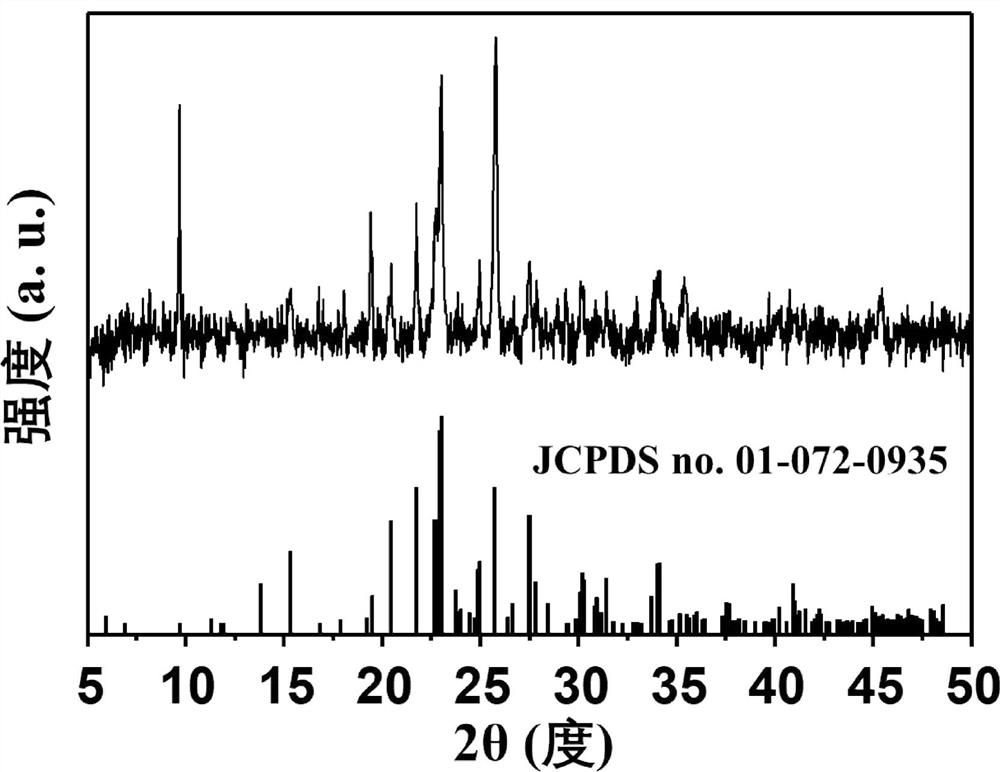

[0047] 4), put the precursor solution obtained in step 3) into a polytetrafluoroethylene reactor, conduct a hydrothermal reaction at 160 °C for 24 h, wash the hydrothermal product, and dry to obtain a yellow-green precursor p...

Embodiment 3

[0051] A monoclinic structure Fe disclosed in this embodiment 2 (MoO 4 ) 3 The preparation method of the nanowire includes the following steps.

[0052] 1), 0.5387 g ferric nitrate nonahydrate ((Fe(NO 3 ) 3 9H 2 O) with 3 mL nitric acid (HNO 3 ) was dissolved in 20 mL of ultrapure water, mixed and stirred to obtain a clear and transparent solution.

[0053] 2), weigh 0.3530 g ammonium molybdate tetrahydrate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, n Fe :n Mo =2:3) were dissolved in 20 mL of ultrapure water and stirred evenly to obtain a clear, colorless solution.

[0054] 3) Add the ferric nitrate nonahydrate solution obtained in step 1) into the ammonium molybdate solution obtained in step 2), and stir for 9 h to obtain a clear brown-yellow solution.

[0055]4), put the precursor solution obtained in step 3) into a polytetrafluoroethylene reaction kettle, perform a hydrothermal reaction at 140 °C for 48 h, wash the hydrothermal product, and dry to obtain a yellow-green prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com