A pretreatment method of raw material oil for the preparation of spinnable mesophase pitch and high-performance pitch-based carbon fiber

A technology of pitch-based carbon fiber and mesophase pitch, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, processing tar pitch/petroleum pitch/natural pitch by selective extraction, and processing tar pitch/petroleum pitch/natural pitch by chemical method It can solve the problems such as the lack of control of the saturation rate of aromatics and olefins, the single pretreatment process, and the complex composition, so as to achieve the effect of low content of heteroatoms and solid impurities, single structure and narrow molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

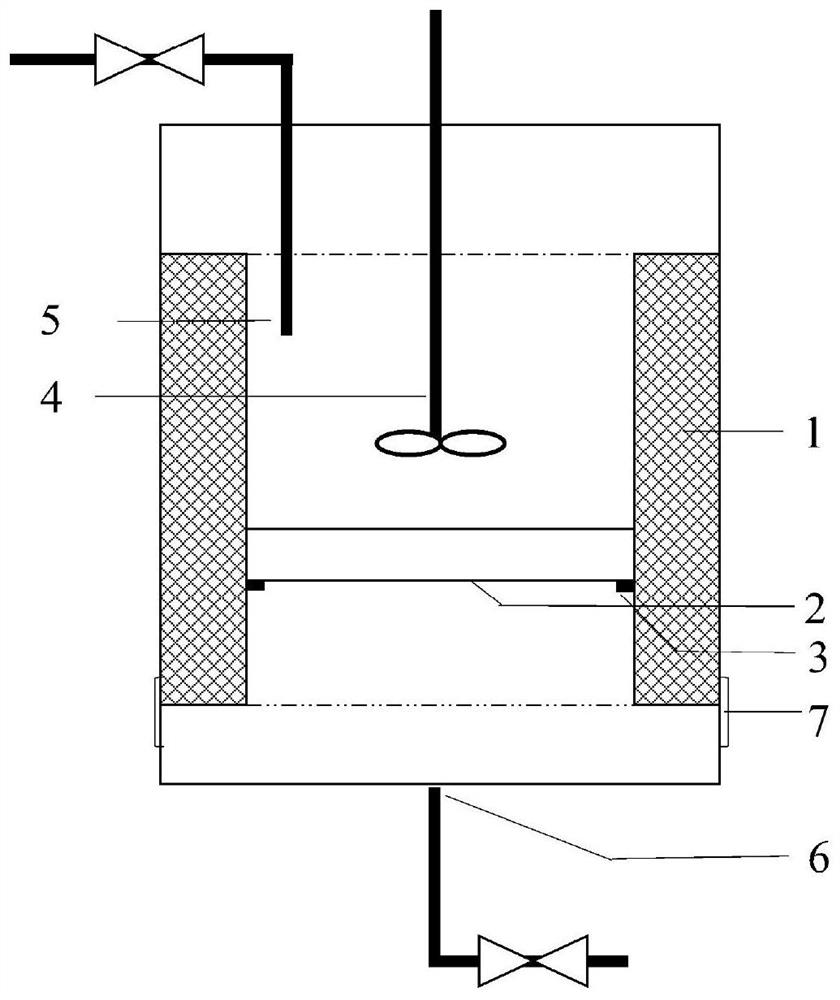

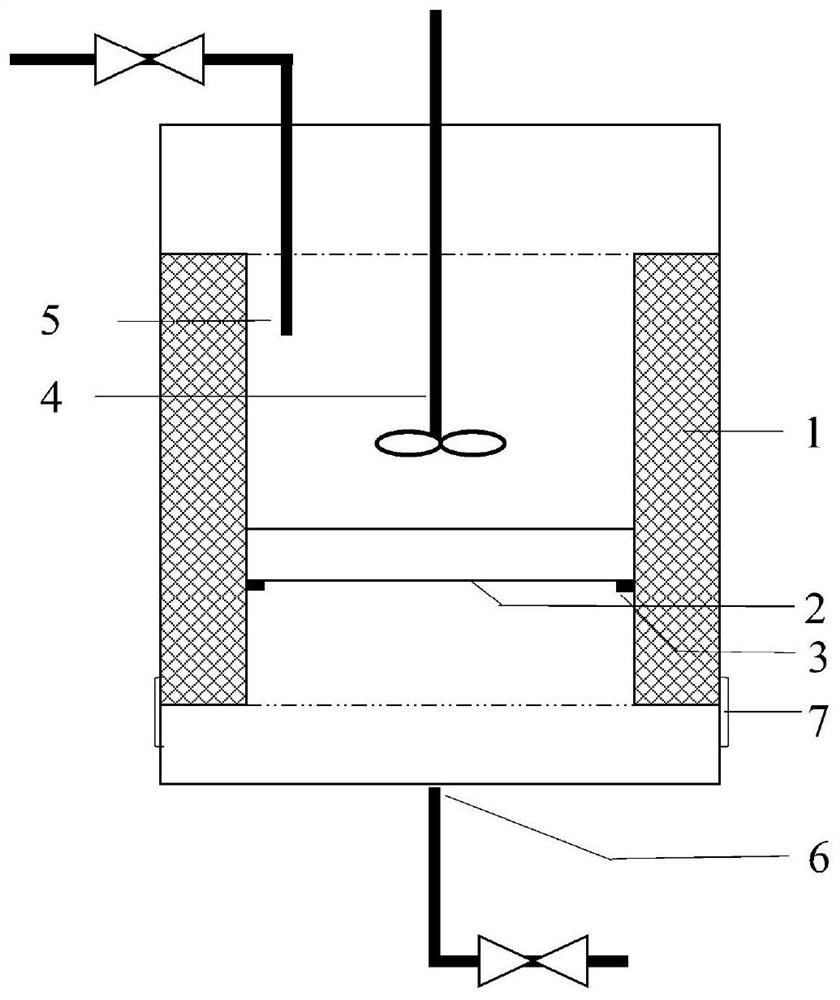

[0029] Under the condition of absolute pressure of 5KPa, 3000g of coal tar was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C, and the mixed component of aromatic-rich distillate oil and extractant furfural (mixing volume ratio 3:1) was obtained by pipeline pump ) by 0.5m 3 The flow rate of / h is sent to the ultrasonic thermal filtration coupling extraction system, the power of the ultrasonic generator is adjusted to 700W, the temperature of the mixed material is 70°C, and a ceramic membrane with a pore size of 20nm is used as the filter medium, and then the filtrate is left to settle and the agent oil Separation to obtain refined raw material oil.

[0030] Add a glass wool pad at the bottom of the gel column, add polystyrene gel, and add a glass wool pad at the top, wet the gel column with 50ml of tetrahydrofuran, mix 100ml of tetrahydrofuran with 300g of the above-mentioned ultrasonic thermal filtration coupling extraction syst...

Embodiment 2

[0032] Under the condition of an absolute pressure of 5KPa, 3000g of ethylene tar was subjected to vacuum precision fractionation to obtain aromatic-rich distillate oil above 300°C, and the mixed composition of aromatic-rich distillate oil and extractant N,N-dimethylformamide was obtained by pipeline pump points (volume ratio 1:3) to 0.6m 3 The flow rate of / h is sent to the ultrasonic thermal filtration coupling extraction system, the power of the ultrasonic generator is adjusted to 700W, the temperature of the mixed material is 70°C, and a ceramic membrane with a pore size of 40nm is used as the filter medium, and then the filtrate is subjected to static sedimentation and solvent oil Separation to obtain refined raw material oil.

[0033] Add a glass wool pad at the bottom of the gel column, add polystyrene gel, and add a glass wool pad at the top, wet the gel column with 50ml of tetrahydrofuran, mix 100ml of tetrahydrofuran with 300g of the above-mentioned ultrasonic therma...

Embodiment 3

[0035] Same as Example 1, the difference is: add hydrogen donating agent decahydronaphthalene to the premixed component of raw material oil and extractant, the consumption of hydrogen donating agent is 3% of raw material oil quality, set the temperature of polycondensation reaction to 440 ℃, The reaction pressure is 4MPa, and the reaction time is 9h, and the softening point is 260°C, the mesophase content is 99.3%, and the mesophase pitch with good spinning performance is obtained.

[0036] The mesophase pitch obtained by the above process is melt-spun under the conditions of spinning pressure 0.6MPa, spinning speed 300m / min, and spinning temperature 310°C, and then pre-oxidized and carbonized to obtain the tensile modulus of the pitch-based carbon fiber It is 410GPa, and the tensile strength is 1.9GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com