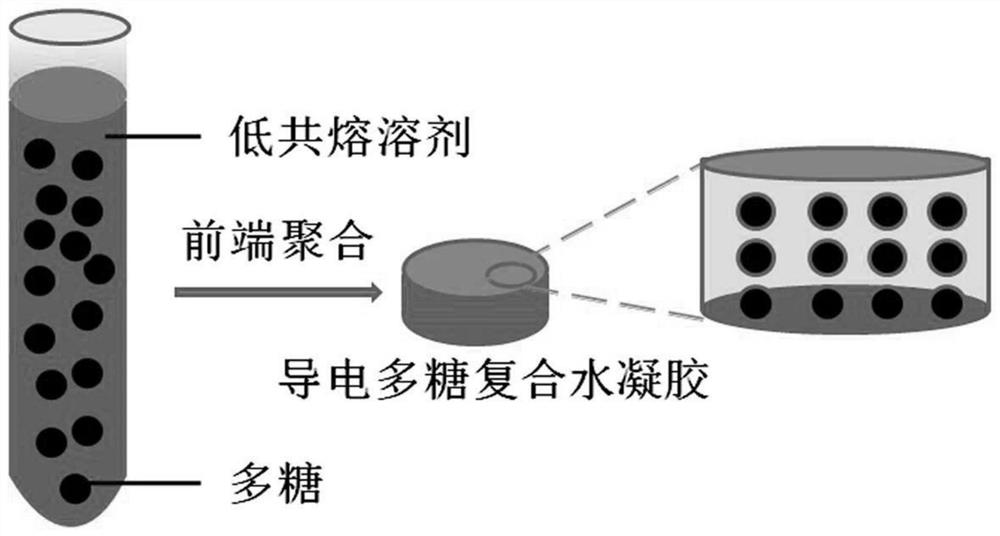

Method for preparing conductive polysaccharide compound hydrogel by adopting front-end polymerization of polysaccharide eutectic solvent mixture solution

A technology of deep eutectic solvent and mixture solution, which is applied in the field of preparation of functional polymer materials, and can solve the problems of using toxic organic solvents, long preparation time, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

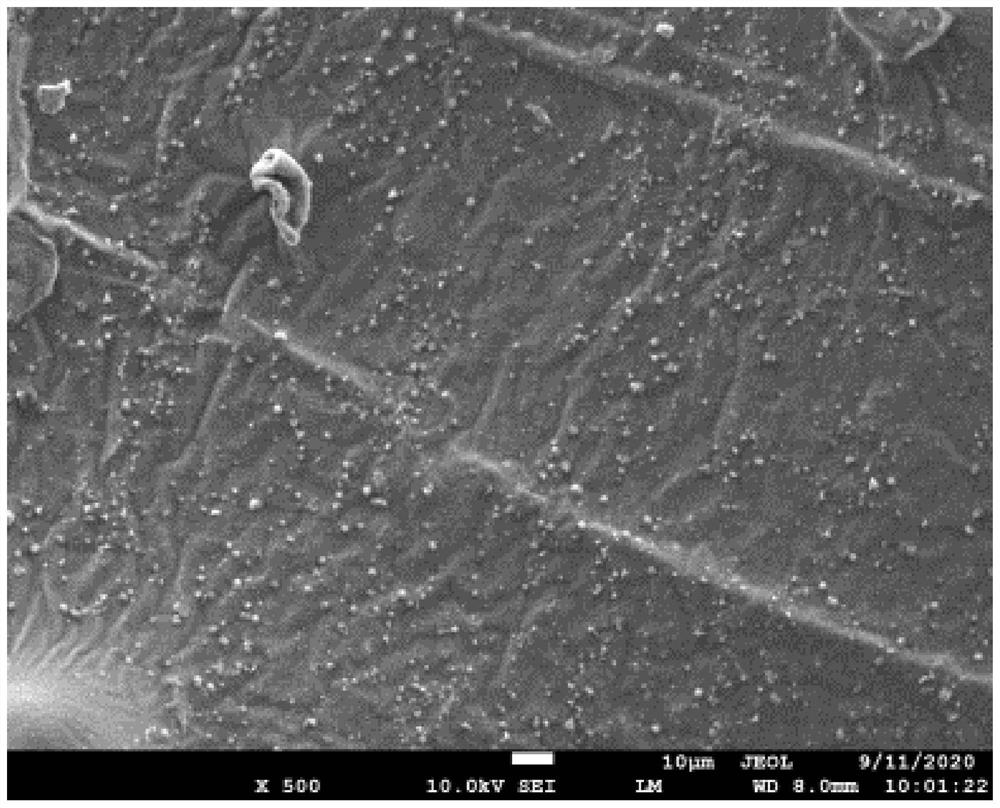

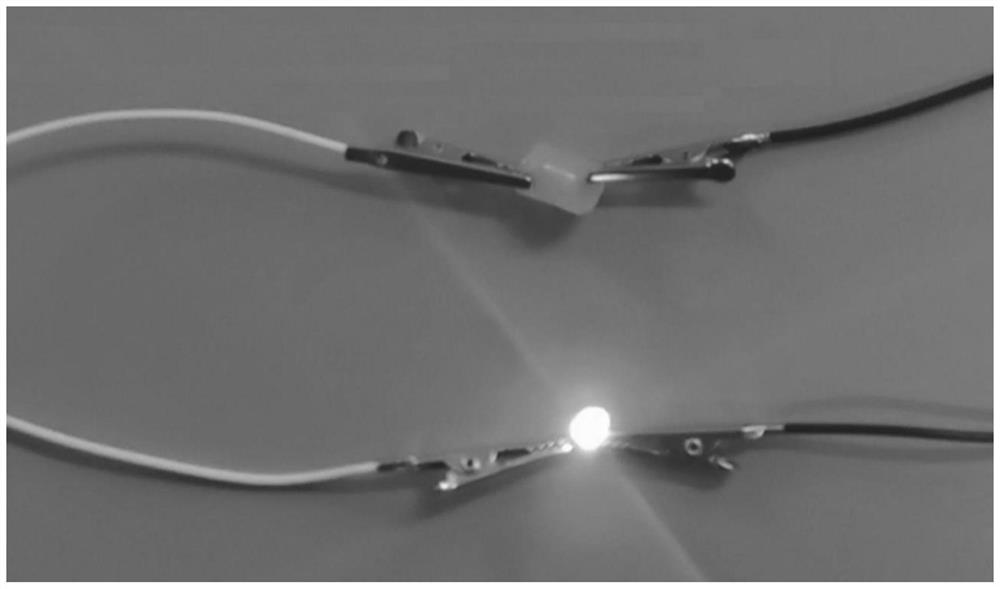

Embodiment 1

[0035] Weigh 7.2 grams of acrylic acid, 12 grams of urea and 14 grams of choline chloride, mix and stir at 85° C. until a transparent and clear liquid is formed to obtain a deep eutectic solvent. Then disperse 0.72 gram of guar gum in the above deep eutectic solvent to obtain mixed solution 1, then add 0.216 gram of divinylstyrene and 0.144 gram of ammonium persulfate to dissolve and form mixed solution 2, then pour mixed solution 2 into the test tube , Use an electric soldering iron to heat the upper end of the test tube to initiate the reaction. After the thermal initiation reaction begins, remove the heat source until all the raw materials in the test tube are converted into polymer gels. After measurement, the movement speed of the front end: 2.3 cm / min. Response time: 4.3 minutes. The composite hydrogel shows light red color, conductivity: 9.26×10 -3 mS / cm, compressive strength: 6.69MPa.

Embodiment 2

[0037] Weigh 8.6 grams of methacrylic acid, 19.2 grams of citric acid and 14 grams of choline chloride, mix and stir at 85° C. until a transparent and clear liquid is formed to obtain a deep eutectic solvent. Then disperse 1.29 grams of starch in the above deep eutectic solvent to obtain mixed solution 1, then add 0.258 grams of N,N'-methylenebisacrylamide and 0.172 grams of potassium persulfate to dissolve to form mixed solution 2, and then mix mixed solution 2 Pour it into a test tube, and use an electric soldering iron to heat the upper end of the test tube to initiate the reaction. After the thermal initiation reaction begins, remove the heat source until all the raw materials in the test tube are converted into polymer gels. After measurement, the movement speed of the front end: 2.2 cm / min. Reaction time: 4.5 minutes. The composite hydrogel shows reddish brown, conductivity: 1.29×10-2 mS / cm, compressive strength: 9.68MPa. .

Embodiment 3

[0039] Weigh 7.1 g of acrylamide, 9.2 g of glycerin and 33.9 g of tetrabutylphosphonium bromide, mix and stir at 85° C. until a transparent and clear liquid is formed to obtain the acrylic deep eutectic solvent. Then 1.42 gram of chitosan is dispersed in above deep eutectic solvent to obtain mixed solution 1, then add 0.071 gram of polyethylene glycol dimethacrylate and 0.0426 gram of azobisisobutyronitrile to dissolve and form mixed solution 2, then Pour the mixed solution 2 into the test tube, heat the upper end of the test tube with an electric soldering iron to initiate the reaction, and remove the heat source after the thermal initiation reaction starts until all the raw materials in the test tube are converted into polymer gels. After measurement, the speed of front end movement: 1.7 cm / min. Response time: 5.9 minutes. The composite hydrogel shows light yellow color, conductivity: 1.23×10 -2 mS / cm, compressive strength: 11.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com