Preparation method and application of multi-layer graphene oxide modified microbial carrier

A microbial carrier, fossil technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of reducing the adhesion speed and amount of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

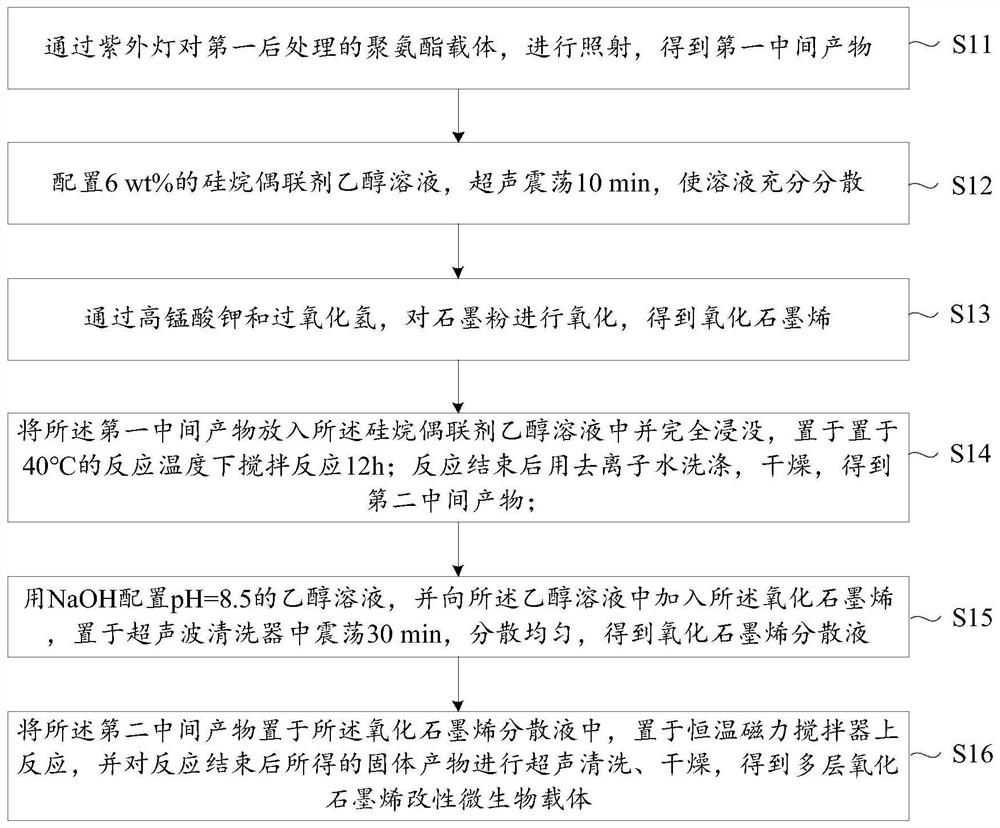

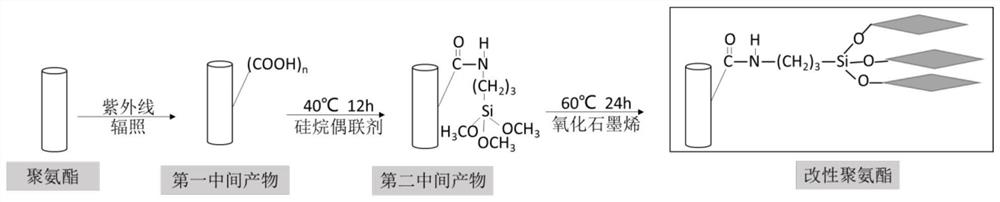

[0051] In a first aspect, the invention provides a method for preparing a multilayer graphene oxide modified microbial carrier, such as figure 1 As shown, the method specifically includes the following steps:

[0052] Step 1 (S11), irradiating the first post-treated polyurethane carrier with an ultraviolet lamp to obtain a first intermediate product.

[0053] In this embodiment, the polyurethane carrier after the first post-treatment is clean and dry. During specific implementation, the clean and dry polyurethane carrier is spread under the ultraviolet lamp and irradiated for 30-60 minutes. During the irradiation process of the ultraviolet lamp, the amide bond in the polyurethane is broken, and the carboxylic acid group is formed to obtain the first intermediate product.

[0054] Optionally, in step 1 of this embodiment, the first post-processing includes:

[0055] Put the polyurethane sponge in an ultrasonic cleaner to vibrate and wash for 30-40 minutes, and then wash it wi...

Embodiment 1

[0070] Embodiment 1 (preparation of multilayer graphene oxide modified microbial carrier)

[0071] (1) Cut the polyurethane carrier into a sphere with a diameter of about 1 cm, put it into an ultrasonic cleaner and shake and wash it for 30 minutes, wash it with deionized water, and dry it in an oven to obtain a clean polyurethane carrier;

[0072] (2) Spread the clean and dry polyurethane carrier under the ultraviolet lamp and irradiate it for 60 minutes, the amide bond in the polyurethane is broken, forming a carboxylic acid group, and obtaining the first intermediate product;

[0073] (3) Prepare 6wt% ethanol solution of silane coupling agent KH550 (γ-aminopropyltriethoxysilane, APTES), and oscillate ultrasonically for 10 minutes to fully disperse the solution;

[0074] (4) Preparation of graphene oxide: Add 1.5g of graphite powder to 200mL of 9:1 sulfuric acid / phosphoric acid mixed solution, stir evenly and place in an ice-water bath; slowly add 9.0g of potassium permangana...

Embodiment 2

[0079] Embodiment 2 (immobilization of microorganisms)

[0080] The graphene oxide-modified polyurethane carrier prepared in Example 1 was used to conduct a biofilm-hanging test. The biological immobilization carrier was first soaked with nutrient solution, placed in a 500mL glass conical flask, and 200mL of nutrient solution was added to the bottle. Inoculate high-efficiency microbial preparations owned by Peking University with independent intellectual property rights, and add at 4g / L. Cultured in a constant temperature shaker, the temperature was set at 30°C.

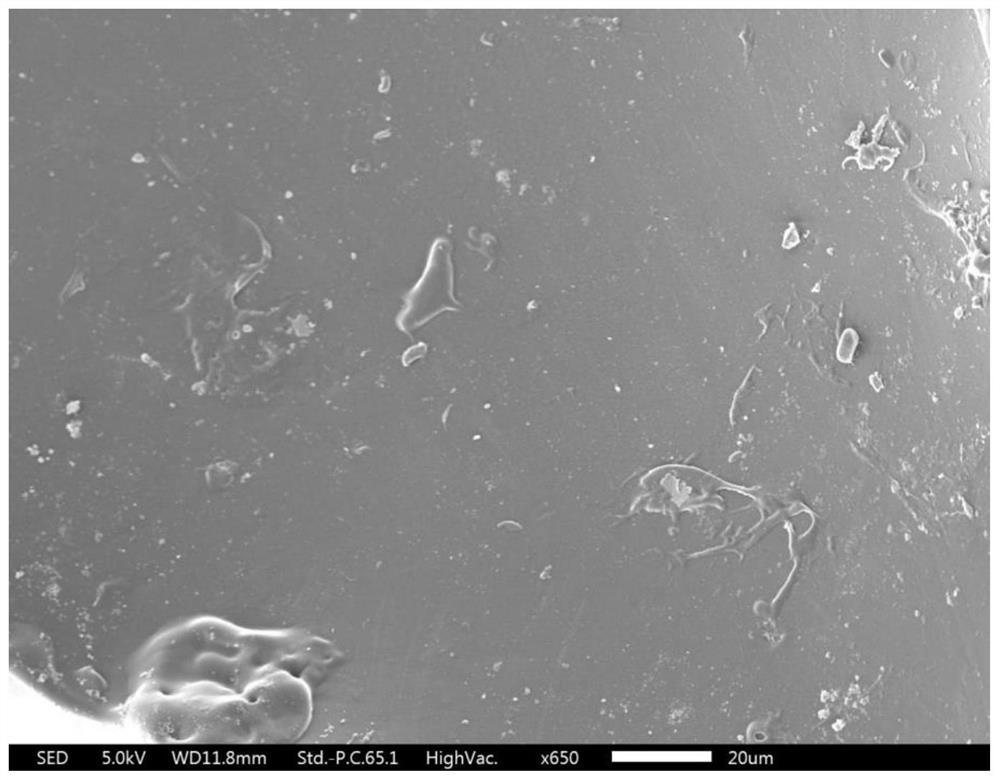

[0081] On the 21st day of culture, Figure 5 Shows the SEM picture of the unmodified polyurethane carrier carrying out the film hanging culture test, Image 6 Shown is the SEM picture of the multilayer graphene oxide modified microbial carrier prepared in Embodiment 1 after the film-hanging culture test. like Figure 5 and 6 As shown, compared with the unmodified polyurethane carrier control, when cultured to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com