Machine-made sand regulator for concrete

A sand conditioner and concrete technology, applied in the field of concrete processing, can solve the problems of uncontrollable gradation, inability to ensure long-term stability of slump, poor gradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Water reducers are made through the following steps:

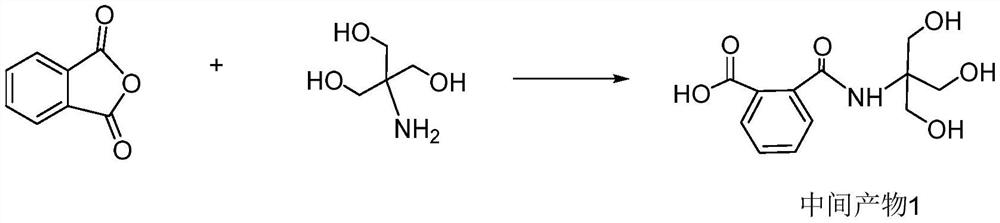

[0040]Step A: Add phthalic anhydride and trishydroxymethylaminomethane into a four-necked flask, then add ethanol to dissolve it completely, then place the four-necked flask in an oil bath and heat to 85°C, and reflux for 10h, then Cool down to room temperature, transfer the solution to a container, place in an oven and dry under vacuum at 35°C to obtain intermediate product 1, wherein the ratio of phthalic anhydride, trishydroxymethylaminomethane and ethanol is 0.1mol: 0.1mol: 150mL;

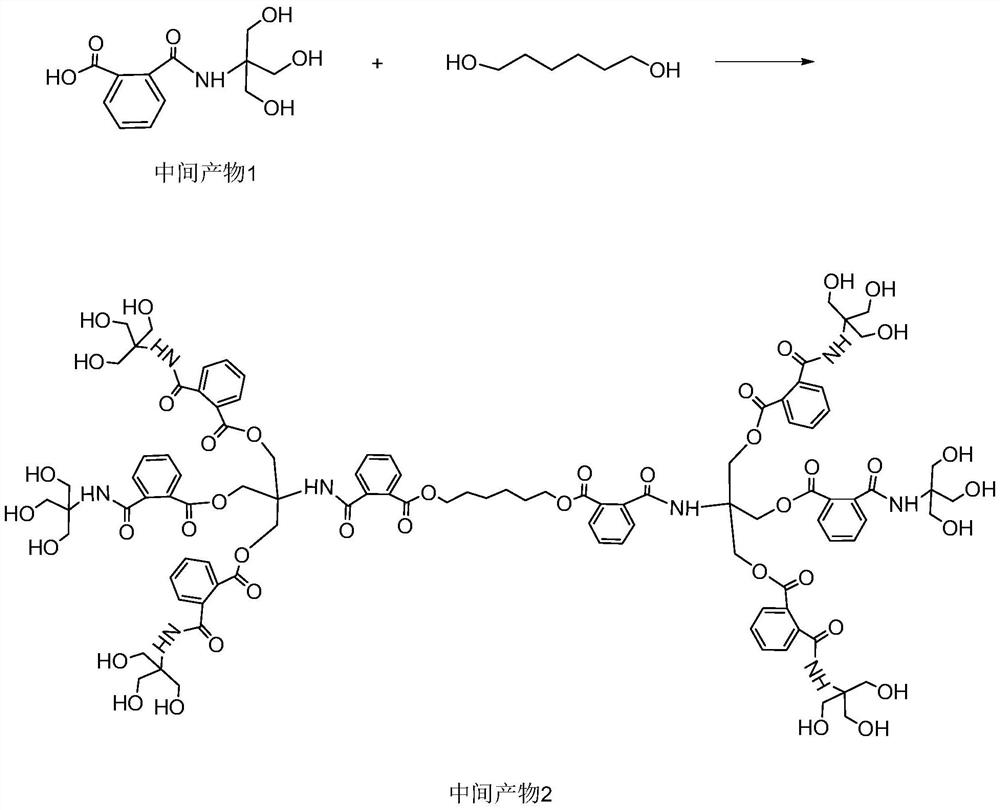

[0041] Step B: Add the intermediate product 1 and 1,2-hexanediol obtained in step A into a four-necked flask, mix well, slowly add concentrated sulfuric acid, and heat the temperature of the reaction system to 65 ° C, under nitrogen protection After reacting under stirring for 3 hours, the intermediate product 2 was finally obtained, wherein the mass ratio of the intermediate product 1, 1,2-hexanediol, and concentrated sulfuric acid...

Embodiment 2

[0045] Water reducers are made through the following steps:

[0046] Compared with embodiment 1:

[0047] The preparation steps are the same, the difference is:

[0048] In step A, the consumption ratio of phthalic anhydride, trishydroxymethylaminomethane and ethanol is 0.1mol:0.12mol:200mL;

[0049] In step B, the mass ratio of intermediate product 1, 1,2-hexanediol and concentrated sulfuric acid is 250:70:2.5;

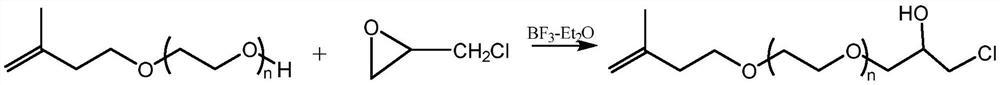

[0050] In step C, the addition mass ratio of prenol polyoxyethylene ether and epichlorohydrin is 120:5; Catalyst A is aluminum chloride; The molecular weight of prenol polyoxyethylene ether is 2400, and small monomer is Hydroxyethyl methacrylate phosphate;

[0051] The intermediate product 2 in step D, the reaction solution obtained in step C, ammonium persulfate and deionized water, solution A, and solution B are in a ratio of 10:60:0.05:80:90:45; solution A is acrylic acid, small single Solution B is a mixture of thioglycolic acid, ascorbic acid and deionized w...

Embodiment 3

[0053] Compared with embodiment 1:

[0054] The preparation steps are the same, the difference is:

[0055] In step A, the consumption ratio of phthalic anhydride, trishydroxymethylaminomethane and ethanol is 0.1mol:0.15mol:350mL;

[0056] In step B, the mass ratio of intermediate product 1, 1,2-hexanediol and concentrated sulfuric acid is 300:90:3;

[0057] In step C, the addition mass ratio of prenol polyoxyethylene ether and epichlorohydrin is 130:7; Catalyst A is ferric chloride; The molecular weight of prenol polyoxyethylene ether is 3600, small monomer It is a mixture of sodium methacrylate and hydroxyethyl methacrylate phosphate in a mass ratio of 1:1;

[0058] The intermediate product 2 in step D, the reaction solution obtained in step C, ammonium persulfate and deionized water, solution A, and solution B are in a ratio of 15:70:0.08:90:100:50; solution A is acrylic acid, small single Solution B is a mixture of thioglycolic acid, ascorbic acid and deionized water at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com