Carbon-doped nickel phosphide composite antibacterial material as well as preparation method and application thereof

A compound antibacterial and phosphorus-doped technology, applied in the field of antibacterial materials, can solve the problems of poor biocompatibility, high cost, and low antibacterial efficiency, and achieve the effect of simple preparation method, low cost, and high antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

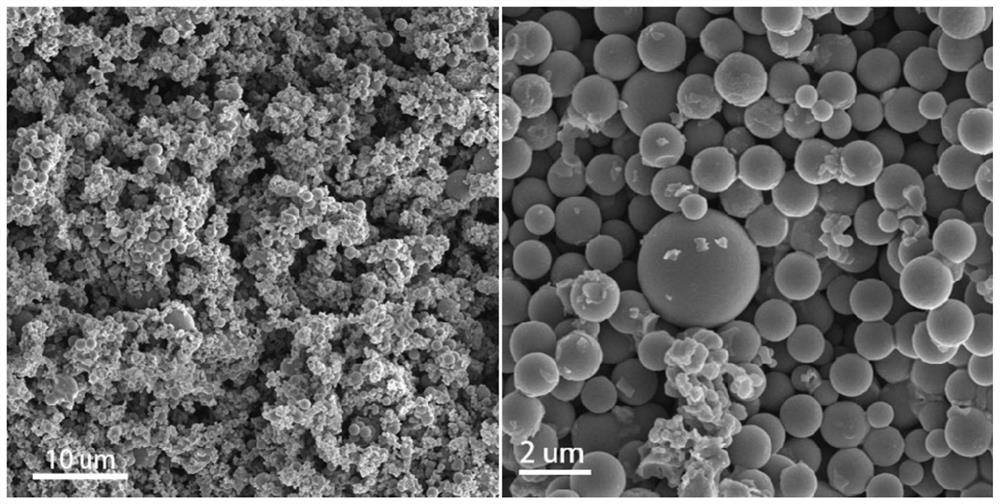

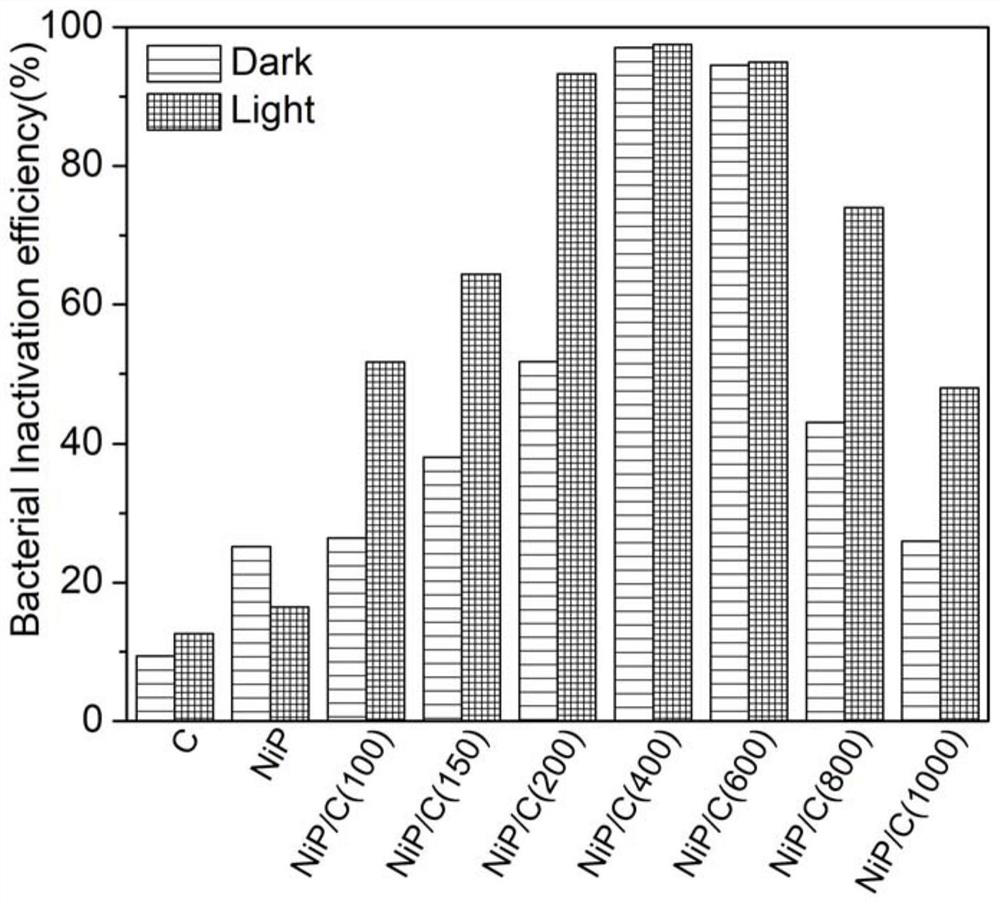

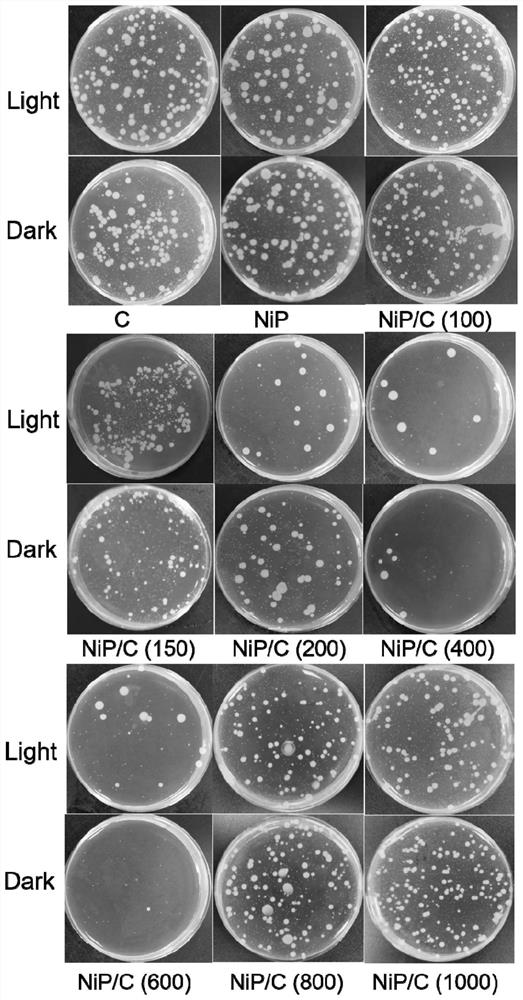

Image

Examples

preparation example Construction

[0027] A preparation method of a composite antibacterial material of carbon-doped nickel phosphide, comprising the following steps:

[0028] (1) Add nano-carbon spheres, nickel nitrate hexahydrate, urea and water into a beaker, stir for 0.5-2 h to obtain a uniform mixture;

[0029] In the mixed solution, the concentration of carbon nanospheres is 1-10 g / L, the concentration of nickel nitrate hexahydrate is 0.01-1.00 mol / L, and the concentration of urea is 0.01-1.00 mol / L;

[0030] (2) Add the above mixed solution into the reactor, then place the reactor in an oven, and conduct a hydrothermal reaction at 100-180 °C for 8-20 h;

[0031] (3) Centrifuge the mixed solution obtained from the above hydrothermal reaction, collect the product, wash it with distilled water and ethanol in sequence, and dry it at 55-65 °C for 10-14 h to obtain a black solid powder;

[0032] (4) Put the above solid powder and sodium hypophosphite on both ends of the porcelain boat, place the porcelain boa...

Embodiment 1

[0036] A preparation method of a composite antibacterial material of carbon-doped nickel phosphide, comprising the following steps:

[0037] (1) Add 0.2 g nanocarbon spheres, 0.2 g Ni(NO 3 ) 2 •6H 2 O and 0.125 g of urea were added to 50 mL of water and stirred for 2 h, and stirred evenly to obtain a mixed solution;

[0038] (2) Transfer the above mixed solution to a 50 mL reaction kettle, and then place the reaction kettle in an oven at 160 ◦ Reaction at C for 10 h;

[0039] (3) Centrifuge the solution obtained after the reaction, collect the product, wash it with distilled water and ethanol in sequence, and obtain the sample after vacuum drying;

[0040] (4) Phosphate the above sample and 100 mg of sodium hypophosphite in a tube furnace with nitrogen gas (nitrogen flow rate 80 mL / min), at 300 ◦ Calcined at C for 2 h, the carbon-doped nickel phosphide composite antibacterial material was obtained.

Embodiment 2

[0042] A preparation method of a composite antibacterial material of carbon-doped nickel phosphide, comprising the following steps:

[0043] (1) Mix 0.15 g nanocarbon spheres, 0.2 g Ni(NO 3 ) 2 •6H 2 O and 0.125 g of urea were added to 50 mL of water and stirred for 2 h, and stirred evenly to obtain a mixed solution;

[0044] (2) Transfer the above mixed solution to a 50 mL reaction kettle, then put the reaction kettle in an oven, at 100 ◦ Reaction at C for 20 h;

[0045] (3) Centrifuge the solution obtained after the reaction, collect the product, wash it with distilled water and ethanol in sequence, and obtain the sample after vacuum drying;

[0046] (4) Phosphate the above sample and 100 mg of sodium hypophosphite in a tube furnace with nitrogen gas (nitrogen flow rate 80 mL / min), at 280 ◦ Calcined at C for 2.2 h, the carbon-doped nickel phosphide composite antibacterial material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com