Solar cell silicon wafer cleaning agent and solar cell silicon wafer cleaning method

A cleaning agent technology for solar cells and silicon wafers, which is applied in the direction of chemical instruments and methods, detergent compositions, detergent compounding agents, etc., and can solve the problem of large thinning of silicon wafers, harsh cleaning liquid use conditions, and non-compliance with environmental protection requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

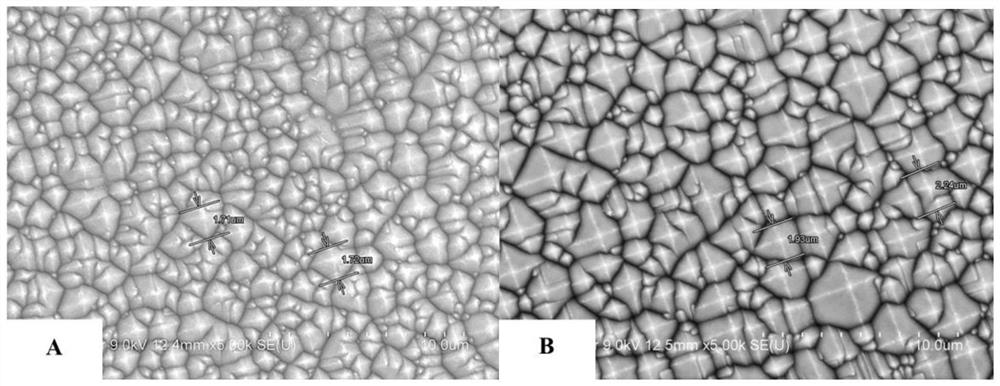

Examples

Embodiment 1

[0039] 1. Prepare solar cell cleaning solution:

[0040] Take a 5L PP measuring cup, add 4.5L deionized water, then add 2g fatty alcohol polyoxyethylene ether, 3g sodium pyrophosphate, 5g sodium acetate, 0.5g protease, 1.5g lipase, 0.8g cellulase, 2.5g ethyl alcohol Diaminetetraacetic acid and 5g of diethyltriaminepentaacetic acid were stirred evenly to prepare a cleaning agent; 250L of deionized water was added to the pre-cleaning tank, 2.5kg of sodium hydroxide was added to dissolve, and the temperature was raised to 45°C. Take 2.5L of the cleaning agent prepared above and add it to the cleaning tank to obtain the cleaning solution.

[0041] 2. Surface cleaning of silicon wafers for solar cells

[0042] Add 400pcs (pieces) of silicon wafers into the cleaning solution for cleaning for 5 minutes, then put them into the deionized water tank for rinsing, and replenish the cleaning solution. After each cleaning batch, add 30ml of cleaning agent, and the cycle of rehydration is c...

Embodiment 2

[0046] 1. Prepare solar cell cleaning solution:

[0047] Take a 5LPP measuring cup, add 4.5L deionized water, then add 1.0g fatty alcohol polyoxyethylene ether, 1.5g polyoxypropylene polyoxyethylene block copolymer, 10g sodium acetate, 1.0g lipase, 0.8g cellulase, 1.2g of amylase and 20g of diethyltriaminepentaacetic acid were mixed evenly to make a cleaning agent; 250L of deionized water was added to the pre-cleaning tank, 2.5kg of sodium hydroxide was added to dissolve, and the temperature was raised to 50°C. Add 2.5L of the cleaning agent prepared above into the cleaning tank to obtain the cleaning solution.

[0048] 2. Surface cleaning of silicon wafers for solar cells

[0049] Add 400pcs of silicon wafers into the cleaning solution for cleaning for 5 minutes, then put them in deionized water for rinsing, and then replenish the cleaning solution, add 30ml of cleaning agent after each cleaning batch, and complete each batch by circulating the rehydration. Silicon wafer cl...

Embodiment 3

[0053] 1. Prepare solar cell cleaning solution:

[0054] Take a 5L PP measuring cup, add 4.5L deionized water, then add 1.4g fatty alcohol polyoxyethylene ether, 30g sodium pyrophosphate, 50g sodium acetate, 0.3g protease, 0.5g lipase, 0.3g cellulase, 15g ethyl alcohol Diaminetetraacetic acid and 15g of diethyltriaminepentaacetic acid were stirred evenly to prepare a cleaning agent; 250L of deionized water was added to the pre-cleaning tank, 2.5kg of sodium hydroxide was added to dissolve, and the temperature was raised to 45°C. Take 2.5L of the cleaning agent prepared above and add it to the cleaning tank to obtain the cleaning solution.

[0055] 2. Surface cleaning of silicon wafers for solar cells

[0056] Add 400pcs (pieces) of silicon wafers into the cleaning solution for cleaning for 5 minutes, then put them into the deionized water tank for rinsing, and replenish the cleaning solution. After each cleaning batch, add 30ml of cleaning agent, and the cycle of rehydration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com