Method and device for separating lysozyme from egg white

A separation device and separation method technology, applied in the direction of sterilization methods, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems of low yield, difficult large-scale production, limited purity, etc., and achieve improved Yield and purity, reduced operating costs, and the effect of reducing adsorption pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

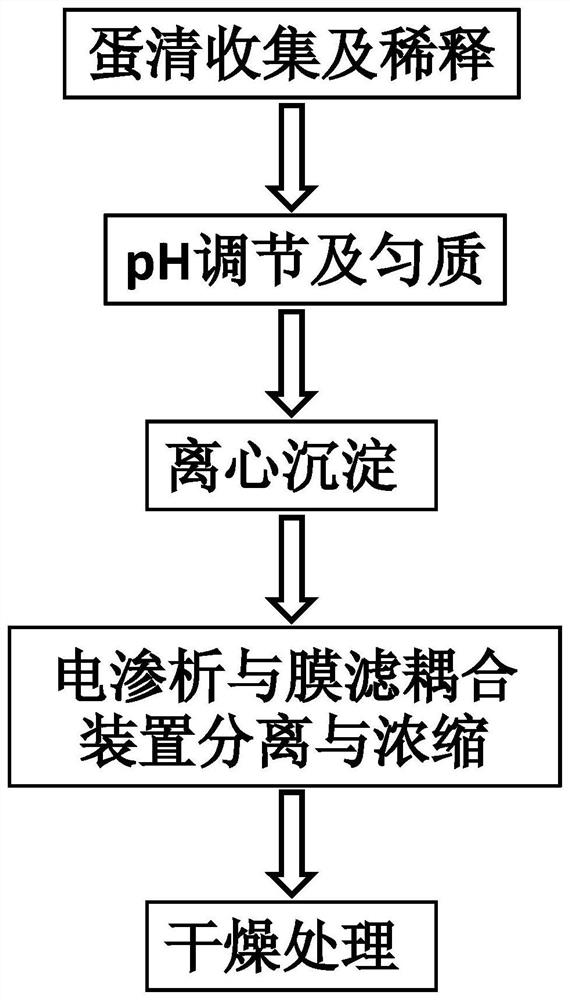

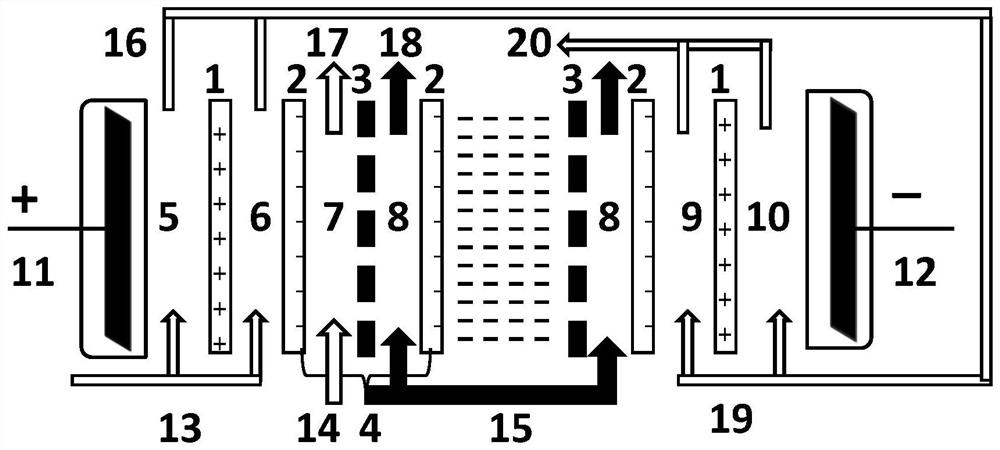

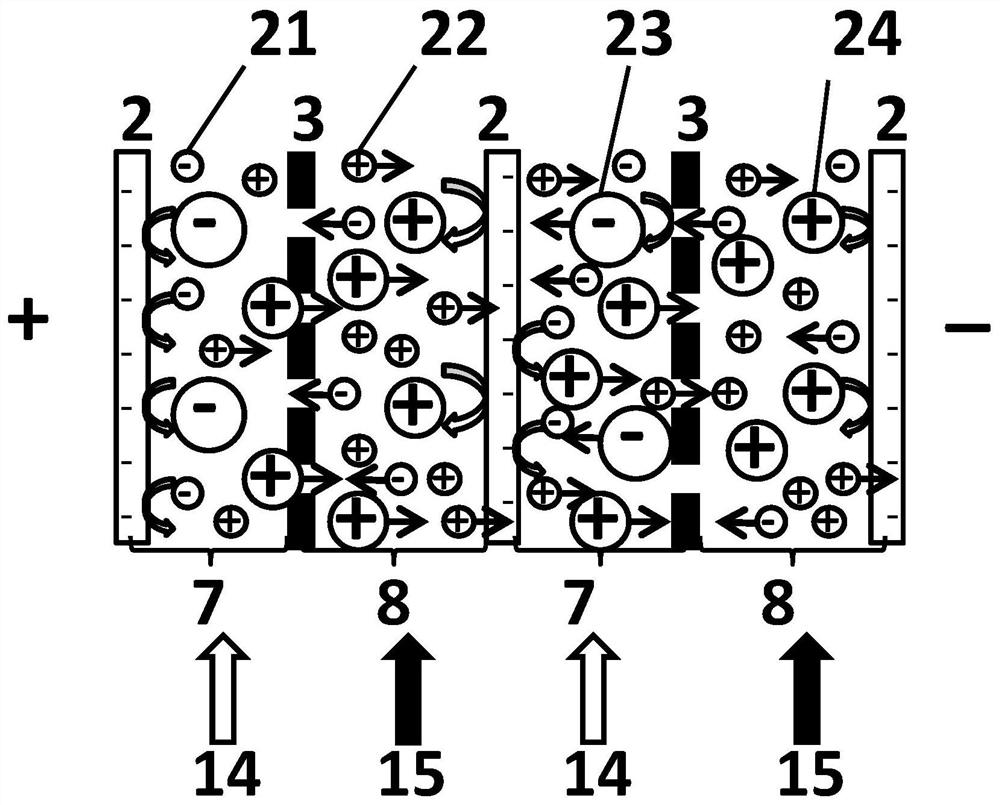

[0055] In this embodiment, fresh eggs are washed and shelled, egg whites and egg yolks are separated by an egg separator, and the egg whites are collected. Take 100 mL of fresh egg white, add 900 mL of phosphate buffer containing 0.9% NaCl to dilute the fresh egg white, adjust the pH to 8.0 with 1.0 M HCl and NaOH, and slowly magnetically stir for 30 min. Then the evenly stirred egg white-phosphate buffer solution was refrigerated and centrifuged at 4°C at a speed of 9000r / min for 15 minutes to remove macromolecular viscous proteins and other impurity precipitates to obtain the supernatant, namely the egg white dilution. The egg white dilution enters a lysozyme separation device in egg white that is inherently coupled by membrane filtration and electrodialysis to further separate and concentrate the lysozyme in it, and vacuum freeze-dry the obtained lysozyme concentrate to obtain a white The powder is the finished lysozyme. The obtained lysozyme was detected by sodium dodecyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com