Orientation material based on magnetic nanofibers as well as preparation method and application of orientation material

A technology of magnetic nano and oriented materials, applied in biochemical equipment and methods, fiber chemical characteristics, pharmaceutical formulations, etc., can solve the problems that oriented nanofibers do not have orientation structure design, cannot be flexibly adjusted and realized, etc. , to achieve low cell adhesion, good biocompatibility, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The magnetic nanofibers are prepared by electrostatic spinning method, including the following steps:

[0072] S1, prepare silk fibroin solution

[0073] (1) Silk degumm: Weigh 25.44g ~ 60G no water NA 2 CO 3 After dissolving in 12L, it is less than the boiling deionized water. After it is dissolved, 30 g to 60 g of a silk or silkworm cocoons are placed in which 15 to 120 min, after removal, the silkwater obtained by deionized water has been washed repeatedly after dehydration. No smooth and greasy feel, put it in a fume hood to dry overnight.

[0074] The above degreased method can also be used in urea delatizing, alkaline protease deprint, neutral soap delay, and tartaric acid degumctate.

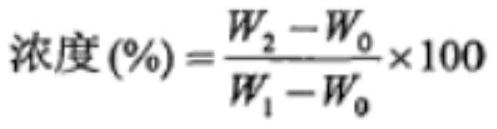

[0075] (2) Silkin protein dissolution: 20 ml of 9 ~ 9.5 mol / L of the lithium bromide solution, rapidly dissolved on the magnetic agitator, then use the filter machine to filter 2 ~ 3 times, the delayed silk is immersed, with tin foil paper The sealing is carried out, and the dissolve...

Embodiment 2

[0118] Electrostatic spinning method is used to prepare magnetic nanofibers, including the following steps:

[0119] S1-S2 is the same as in Example 1, and the step S3 of Example 1 is omitted.

[0120] In S4, a 1% chloride solution was added to the silk fibroin solution, and the mixture was mixed and dissolved in 50% to 70% PEG-400 solution, formulated into a spinning liquid. The mass ratio between the ferrous chloride and silk venein protein is 1: 50 to 200.

[0121] The composite nanofibers are obtained by electrostatic spinning by electrostatic spinning, and the nanofibers are 0.06% h. 2 O 2 Soak the stirring in the solution, add 3 mol / L sodium hydroxide solution to adjust the pH to 11 to 13, warmed to 55 ° C, adjust the stirring speed of 60 rpm, and stop heating after stirring for 3 h, to obtain magnetin compound nanofibers. Dispersion, placing a beaker in an ultrasonic cleaning machine After 5 min, after 20 min, these magnetic nanofibers gathered at the bottom of the beaker...

Embodiment 3

[0125] Electrostatic spinning method is three-step preparation of magnetic nanofibers, including the following steps:

[0126] S1-S3 is the same as in Example 1.

[0127] Different from one step, the magnetic nanoparticles prepared in step S3 are not added in S4.

[0128] The electrospun nanofibers formed in S5 were incubated in a suspension containing magnetic nanoparticles (10 ~ 50% V: V) for more than 3 hours, so as to adsorb the silk fibers and magnetic nanoparticles by electrostatic adsorption. The interaction, the chemical crosslinking is sufficiently bonded, and then centrifuged with a 25000 r / min at high speed centrifuge, and the centrifugal washing was repeated three times to obtain a magnetin-composite nanofiber.

[0129] S6-S9 is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com