A salt-resistant fracturing fluid thickener and preparation method thereof

A fracturing fluid thickener and salt-type technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problem of high market price of betaine salt-resistant monomer, which is not suitable for large-scale promotion and application, Tolerate the problems of high salinity and limited improvement, achieve the effect of shortening the preparation time, avoiding steric hindrance between groups, and good temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

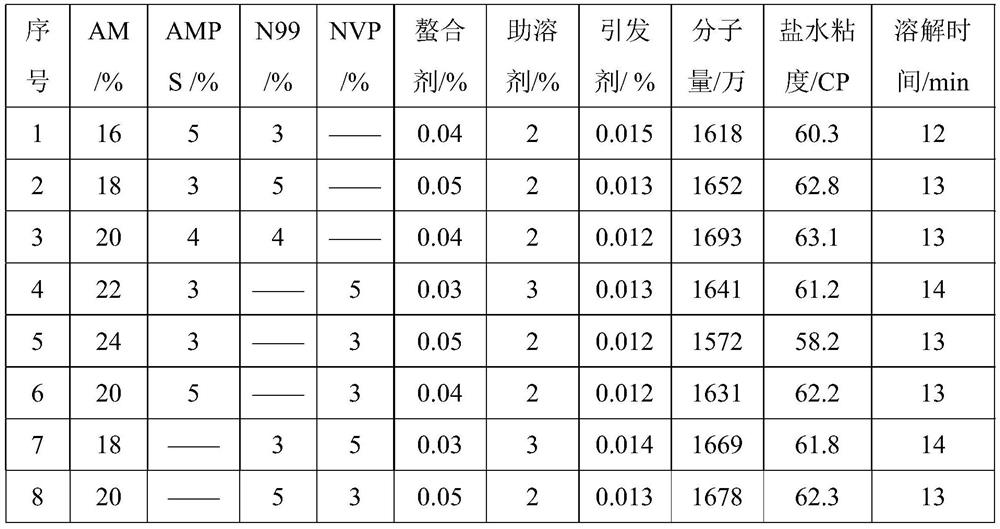

Examples

preparation example Construction

[0027] The invention provides a preparation method of a salt-resistant fracturing fluid thickener, comprising the following steps:

[0028] Step 1. Add the salt-resistant monomer, acrylamide, chelating agent, co-solvent, initiator and deionized water into the container for mixing and dissolving, and adjust the pH of the solution to 6.5-7.5;

[0029] Step 2. Open the nitrogen valve to vent nitrogen and remove oxygen for 20-30 minutes;

[0030] Step 3. Turn on the polymerization lamp, put the solution under the ultraviolet light for 50-80 minutes, and light polymerization;

[0031] Step 4. Take out the rubber block, send the rubber block product to a granulator for granulation, and send it to a fluidized bed for drying after granulation. After drying, send it to a pulverizer for crushing, and then sieve according to the particle size requirements. After packaging Then send it to the finished product warehouse for storage.

[0032] In the present invention, by selecting monomer...

Embodiment 1

[0049] Add 19% acrylamide, 4% N-vinylpyrrolidone and 4% AMPS to a 1L beaker, add 0.04% EDTA solution, neutralize with 32% caustic soda to pH = 7.5, add 2% co-solvent (co-solvent is nano Cellulose) and 0.01% initiator solution (2,2'- azobisisobutylamidine dihydrochloride and azobisisopropylimidazoline hydrochloride 1:1), add water to a total weight of 600g, After completely dissolving, pass nitrogen for 20 minutes, irradiate under ultraviolet light for 60 minutes, take out the rubber block and granulate, dry and pulverize at 50° C. to obtain a 0.5% solution in compound brine (4.9% sodium chloride and 0.1% calcium chloride) with a molecular weight of 16.13 million A product with a viscosity of 59.3 cp and a dissolution time of 14 minutes.

Embodiment 2

[0051] Add 20% acrylamide, 4% N,N-dimethylacrylamide and 4% AMPS into a 1L beaker, add 0.03% EDTA solution, neutralize with 32% caustic soda to pH = 7.5, add 2% co-solvent ( The cosolvent is nanocellulose) and 0.015% initiator solution (4,4'-azobis(4-cyanovaleric acid) and azodiisopropylimidazoline hydrochloride 1:1), replenishing water to total The weight is 600g, after completely dissolving, pass nitrogen for 20min, irradiate under ultraviolet light for 70min, take out the rubber block and granulate, dry and pulverize at 50°C, obtain molecular weight 16.59 million, compound brine (4.9% sodium chloride and 0.1% calcium chloride) A product with a 0.5% solution viscosity of 61.7cp and a dissolution time of 13 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com