Boric acid derivative modified binder and lithium ion battery containing same

A binder and copolymer technology, applied in the direction of ester copolymer binders, adhesives, battery electrodes, etc., can solve the problems of poor bonding performance of binders, achieve low-temperature performance improvement, improve cycle performance, and expansion rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] [Preparation method of copolymer]

[0079] The present invention also provides the preparation method of above-mentioned copolymer, promptly prepares by the method for emulsion polymerization, and described method comprises the following steps:

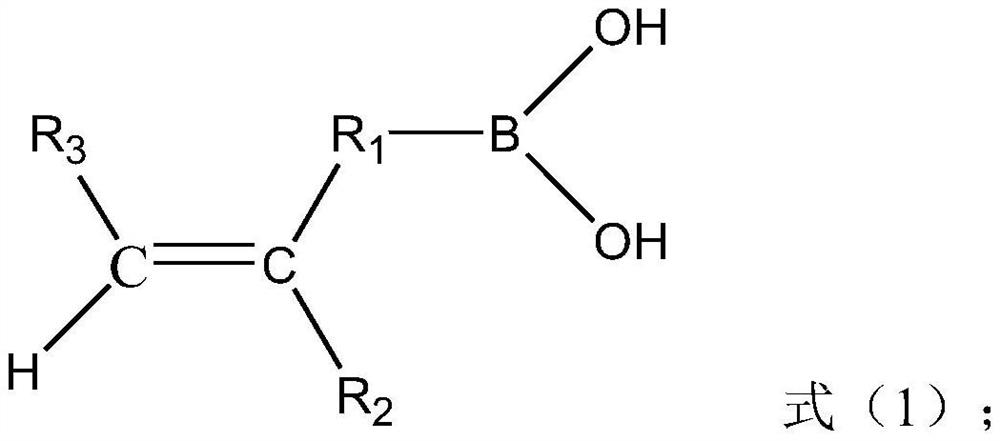

[0080] The comonomer represented by the formula (1) is mixed with a matrix monomer and optionally a functional monomer, passed through an inert gas, and reacted to prepare the copolymer.

[0081] Wherein, the definitions of comonomer, matrix monomer and functional monomer represented by formula (1) are as mentioned above.

[0082] In a preferred solution, the inert gas is one of high-purity nitrogen and high-purity argon.

[0083] In a preferred embodiment, the reaction temperature is 30-120° C., and the reaction time is 5-24 hours.

[0084] In a preferred solution, depending on the difference of the matrix monomer and optionally the functional monomer, an auxiliary agent may also be added during the reaction. Exemplarily, t...

Embodiment 1

[0128]Add 30 parts (parts by mass, same below) of styrene, 70 parts of butadiene, 0.4 parts of acrylic acid, 0.1 part of divinylbenzene, and 2 parts of p-vinylbenzeneboronic acid (shown in formula 1-1) to the reaction kettle in sequence , 200 parts of water, 4.5 parts of sodium stearate, 0.5 part of molecular weight modifier dodecanethiol, nitrogen protection, stirring at 300 rpm, and heating up to 65°C. After continuing to stir for 20 minutes, add 0.31 parts of potassium persulfate, keep warm at 60°C, condense, continue to stir at 300rpm, and react for 7h. After the reaction is over, adjust the pH value with ammonia water, filter the gel therein with 200 mesh gauze, and obtain the Styrene-butadiene rubber emulsion binder modified by vinylbenzeneboronic acid, the glass transition temperature of the emulsion binder is 16°C, the average particle size is 168nm, the PDI is 0.06, the viscosity is 10-50mPa·s, and the solid content It is 40-42wt%, pH=6.5-7.5.

[0129] Disperse the p...

Embodiment 2

[0133] Add 33 parts of styrene, 67 parts of butadiene, 0.15 parts of divinylbenzene, 3 parts of boric acid derivatives shown in formula 1-3, 155 parts of water, 2 parts of acrylamide, 6 parts of stearin in the reaction kettle Na2SO4, 0.6 parts of molecular weight regulator dodecanethiol, nitrogen protection, stirring at 300 rpm, and heating up to 60°C. After continuing to stir for 20 minutes, add 0.3 parts of ammonium persulfate, keep warm at 65°C, condense, continue to stir at 300 rpm, and react for 6 hours. After the reaction is completed, adjust the pH with ammonia water, and filter the gel in it with 200-mesh gauze to obtain carboboric acid Derivative modified styrene-butadiene rubber emulsion binder, the glass transition temperature of the emulsion binder is 20°C, the average particle size of the emulsion binder is 165nm, the PDI is 0.036, and the viscosity is 15-50mPa· s, solid content is 39-41wt%, pH=7-8.

[0134] The process flow of the method for making the lithium-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com