Polycarboxylate superplasticizer as well as preparation method and application thereof

A technology of water reducing agent and polycarboxylic acid, applied in the field of building materials, can solve problems such as poor compatibility, achieve good dispersion ability and adaptability, improve working environment and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

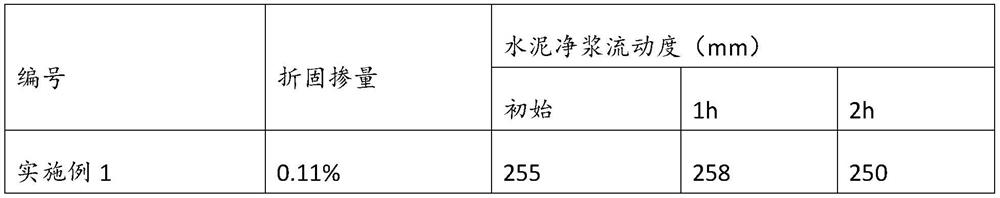

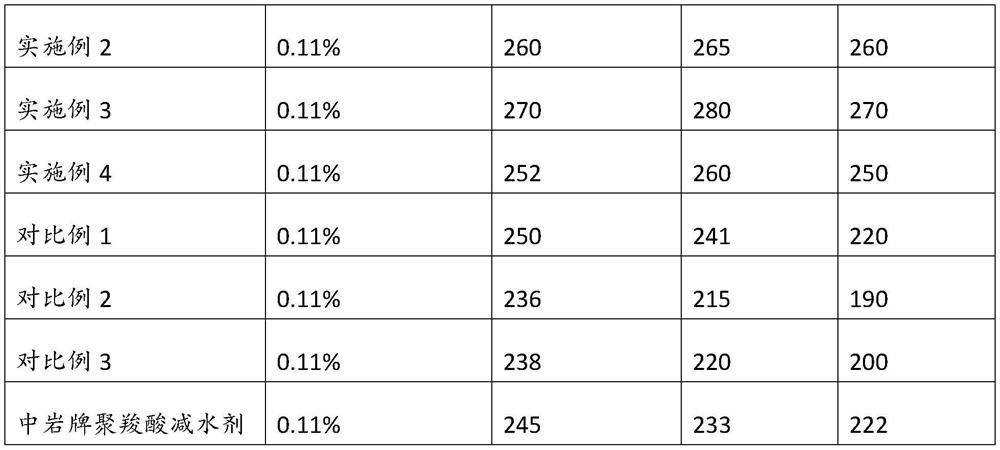

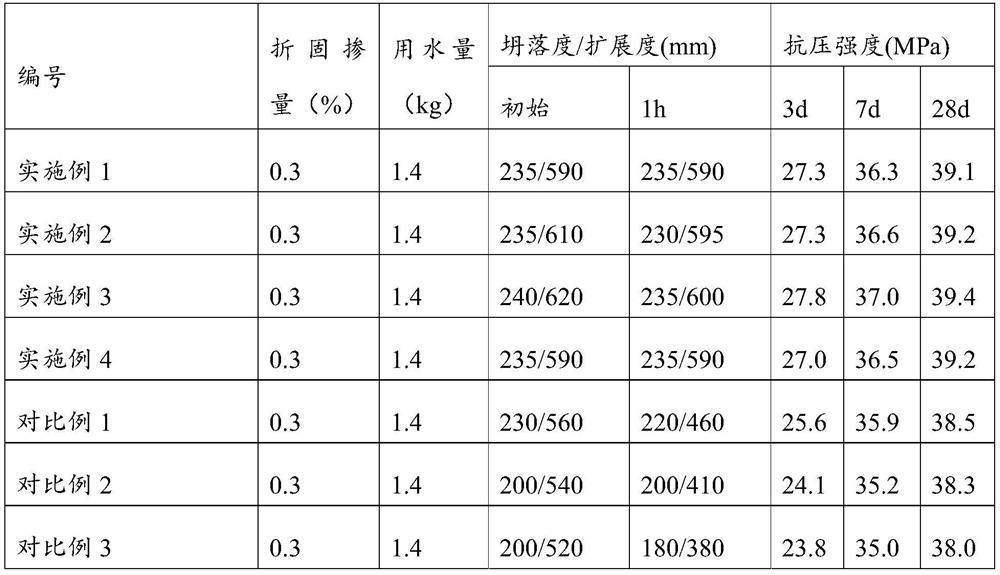

Examples

Embodiment 1

[0094] This embodiment prepared a polycarboxylate water reducer, the specific process is:

[0095] S1. Add nano-silica, hydroxyethyl acrylate and coupling agent to deionized water at a molar ratio of 1:1:1. After uniform dispersion, stir and react at 100°C for 3.5h, cool to room temperature, and then filter , washing and vacuum drying to obtain ester-modified silica;

[0096] S2. Mix 0.33g E51, 36.25g deionized water and 1.23g mercaptoethanol to prepare an aqueous solution, which is recorded as material A;

[0097] S3. Mix 30 g of acrylic acid, 15 g of the ester-modified silicon dioxide obtained in step S1, and 10 g of deionized water to prepare an aqueous solution, which is recorded as material B;

[0098] S4. 365g ethylene glycol monovinyl polyethylene glycol ether and 258g deionized water are added in the reactor, after stirring for 5 minutes, add 1g ferrous sulfate solution (mass fraction is 1%), add 2.37g after 5 minutes Hydrogen peroxide (mass fraction is 27.5%), add m...

Embodiment 2

[0101] This embodiment prepared a polycarboxylate water reducer, the difference between the specific process and Example 1 is:

[0102] (1) In step S2, the mass of mercaptoethanol is 1.13g.

Embodiment 3

[0104] This embodiment prepared a polycarboxylate water reducer, the difference between the specific process and Example 1 is:

[0105] (1) In step S1, the small ester molecule is hydroxypropyl acrylate instead of hydroxyethyl acrylate;

[0106] (2) In step S3, the mass of acrylic acid is 32g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com