Acid preparation composition for improving production performance of meat pigeons and preparation method and application of acid preparation composition

A technology of production performance and composition, applied in the application, animal feed, animal feed, etc., can solve the problems of human health hazards, treatment failure, increased drug resistance, etc., to increase the survival rate, vigorous qi and blood, and reduce harmful bacteria. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

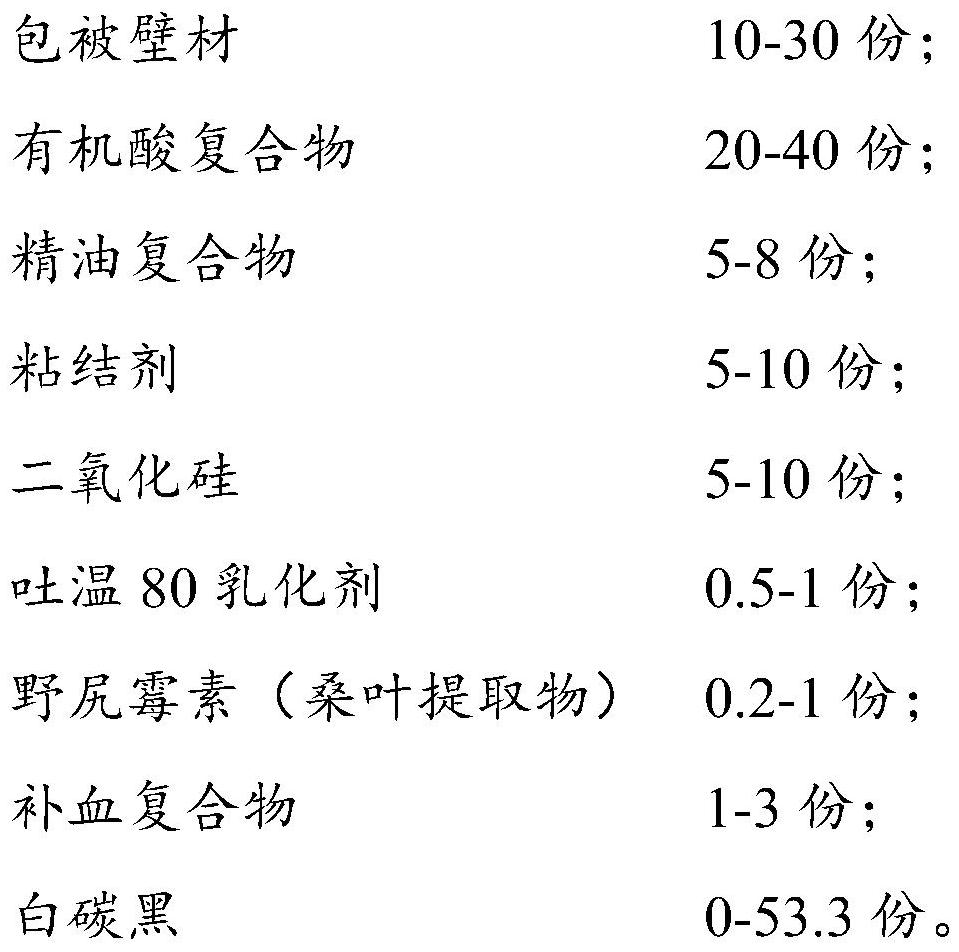

[0052] The acid preparation composition for improving the production performance of meat pigeons in this embodiment includes 10% of coating wall material, 5% of binding agent, 0.5% of Tween 80 emulsifier, 5% of silicon dioxide, 20% of organic acid compound, essential oil Compound 5%, Nojirimycin (mulberry leaf extract) 0.2%, blood enriching compound 1%, and white carbon black as the balance.

[0053] In this embodiment, the coated wall material is ethyl cellulose and / or polyacrylic resin No. IV, hydrogenated palm oil and / or chitosan; the binding agent is microcrystalline cellulose and / or cornstarch, β-cyclogluter Alcohol and / or maltodextrin.

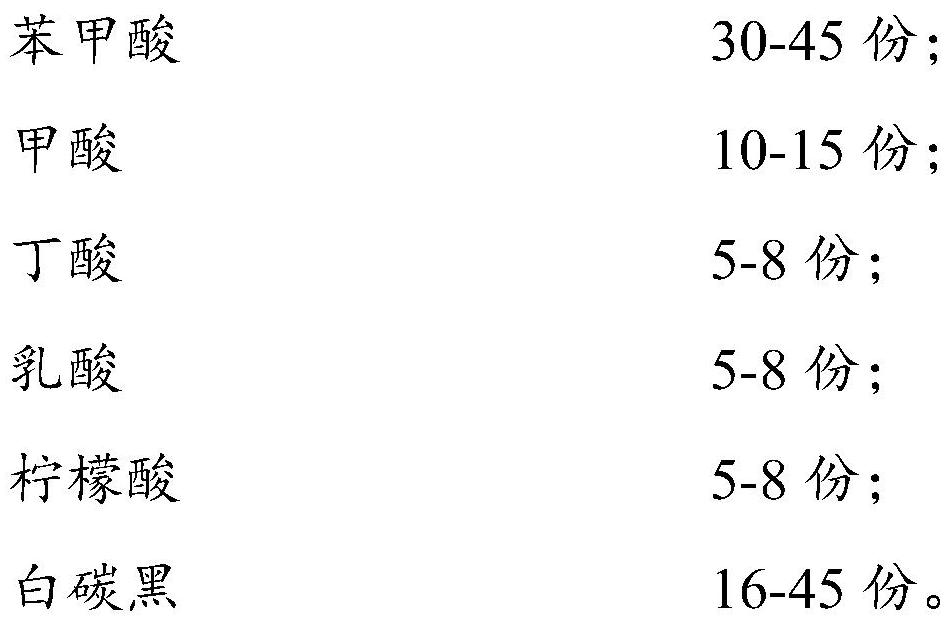

[0054] Further, the organic acid complex is composed of 30% benzoic acid, 10% formic acid, 5% butyric acid, 5% lactic acid, 5% citric acid and the rest white carbon black.

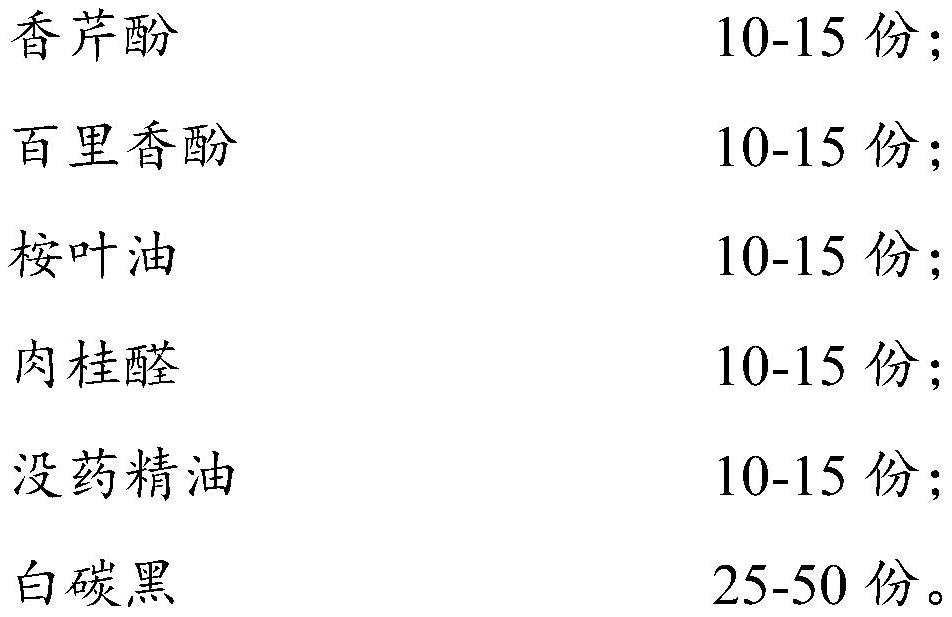

[0055] Further, the essential oil compound is composed of 10% carvacrol, 10% thymol, 10% eucalyptus oil, 10% cinnamaldehyde, 10% myrrh essential oil and white carbo...

Embodiment 2

[0070] The acid preparation composition for improving the production performance of meat pigeons in this embodiment includes 20% of coating wall material, 7.5% of binding agent, 0.75% of Tween 80 emulsifier, 7.5% of silicon dioxide, 30% of organic acid compound, essential oil Compound 6.5%, Nojirimycin (Mulberry Leaf Extract) 0.6%, Blood Enriching Compound 2%, and the balance white carbon black.

[0071] In this embodiment, the coated wall material is ethyl cellulose and / or polyacrylic resin No. IV, hydrogenated palm oil and / or chitosan; the binding agent is microcrystalline cellulose and / or cornstarch, β-cyclogluter Alcohol and / or maltodextrin.

[0072] Further, the organic acid complex is composed of 37.5% benzoic acid, 12.5% formic acid, 6.5% butyric acid, 6.5% lactic acid, 6.5% citric acid and white carbon black as the balance.

[0073] Further, the essential oil compound is composed of 12.5% carvacrol, 12.5% thymol, 12.5% eucalyptus oil, 12.5% cinnamaldehyde, 1...

Embodiment 3

[0088] The acid preparation composition for improving the production performance of meat pigeons in this embodiment includes 30% of coating wall material, 10% of binding agent, 1% of Tween 80 emulsifier, 10% of silicon dioxide, 40% of organic acid compound, essential oil Compound 8%, Nojirimycin (mulberry leaf extract) 1%, blood enriching compound 3%, and white carbon black as the balance.

[0089] In this embodiment, the coated wall material is ethyl cellulose and / or polyacrylic resin No. IV, hydrogenated palm oil and / or chitosan; the binding agent is microcrystalline cellulose and / or cornstarch, β-cyclogluter Alcohol and / or maltodextrin.

[0090] Further, the organic acid complex is composed of 45% benzoic acid, 15% formic acid, 8% butyric acid, 8% lactic acid, 8% citric acid and the rest white carbon black.

[0091] Further, the essential oil compound consists of 15% carvacrol, 15% thymol carvacrol, 15% eucalyptus oil carvacrol, 15% cinnamon aldehyde carvacrol, 15% myrrh e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com