Heavy metal wastewater adsorbent

A technology for adsorbents and heavy metals, applied in the fields of alkali metal compounds, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as complex operation process, high operating cost, secondary pollution, etc., and achieve analytical High efficiency, good magnetic response, and the effect of solving the problem of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Heavy metal wastewater adsorbents include dextran-based adsorbents, and the dextran-based adsorbents are specifically prepared through the following procedures:

[0055] Step 1, the FeCl 3 ·6H 2 O and sodium acetate were dissolved in ethylene glycol, polyethylene glycol was added and stirred vigorously until completely dissolved, then reacted at 200°C for 5 hours, cooled to room temperature, separated repeatedly with a magnet, washed 3 times with absolute ethanol, and dried to obtain Magnetic Fe 3 o 4 Nanoparticles; FeCl 3 ·6H 2 The consumption ratio of O, sodium acetate, ethylene glycol and polyethylene glycol is 1mmol: 3.2mmol: 8mL: 0.11mmol;

[0056] Step 2, the magnetic Fe 3 o 4 Ultrasonic dispersion of nanoparticles in silane coupling agent G570 ethanol solution, after stirring for 12 hours, repeated separation with magnet, washing with absolute ethanol for 3 times, drying to obtain modified magnetic Fe 3 o 4 Nanoparticles; Magnetic Fe 3 o 4 The dosage r...

Embodiment 2

[0059] Heavy metal wastewater adsorbents include dextran-based adsorbents, and the dextran-based adsorbents are specifically prepared through the following procedures:

[0060] Step 1, the FeCl 3 ·6H 2 Dissolve O and sodium acetate in ethylene glycol, add polyethylene glycol and stir vigorously until completely dissolved, then react at 220°C for 3 hours, cool to room temperature, separate repeatedly with a magnet, wash twice with absolute ethanol, and dry to obtain Magnetic Fe 3 o 4 Nanoparticles; FeCl 3 ·6H 2 The consumption ratio of O, sodium acetate, ethylene glycol and polyethylene glycol is 1mmol: 3.5mmol: 10mL: 0.12mmol;

[0061] Step 2, the magnetic Fe 3 o 4 Ultrasonic dispersion of nanoparticles in the silane coupling agent G570 ethanol solution, after stirring for 10 hours, repeated separation with a magnet, washing with absolute ethanol twice, drying to obtain the modified magnetic Fe 3 o 4 Nanoparticles; Magnetic Fe 3 o 4 The dosage ratio of nanoparticles...

Embodiment 3

[0064] Heavy metal wastewater adsorbents include dextran-based adsorbents, and the dextran-based adsorbents are specifically prepared through the following procedures:

[0065] Operation 1, with embodiment 1;

[0066] Step 2, the vinyl silane coupling agent is prepared by the following method: add absolute ethanol to L-allylglycine and silane coupling agent KH560, react in an oil bath at 120°C for 6 hours under the protection of nitrogen, distill under reduced pressure, and collect The target fraction is dried to obtain a vinyl silane coupling agent; all the other are the same as in Example 1;

[0067] Operation 3 is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

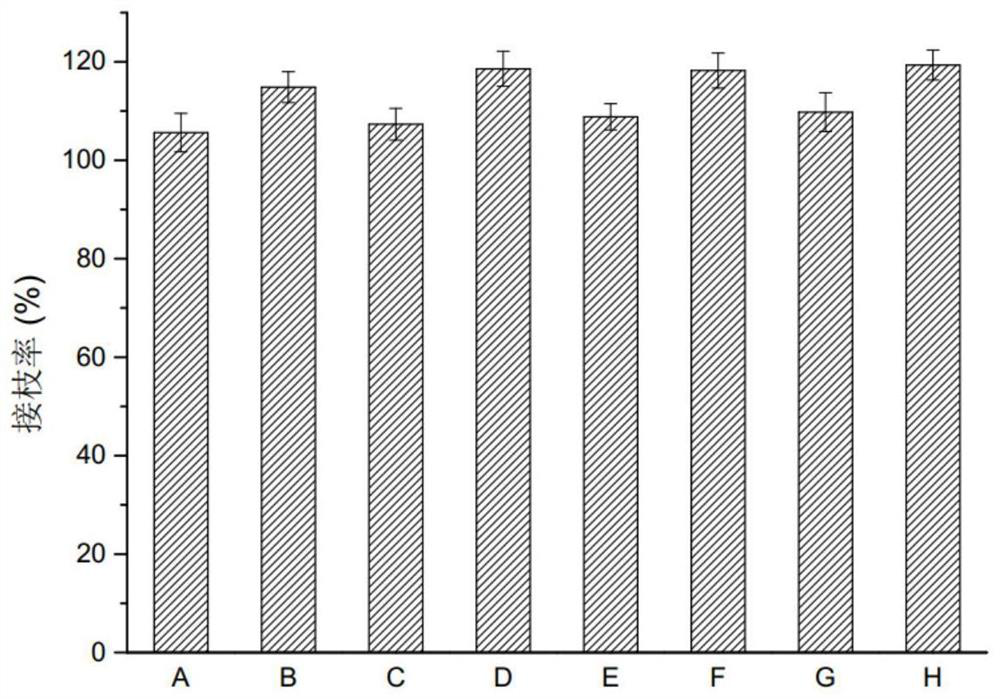

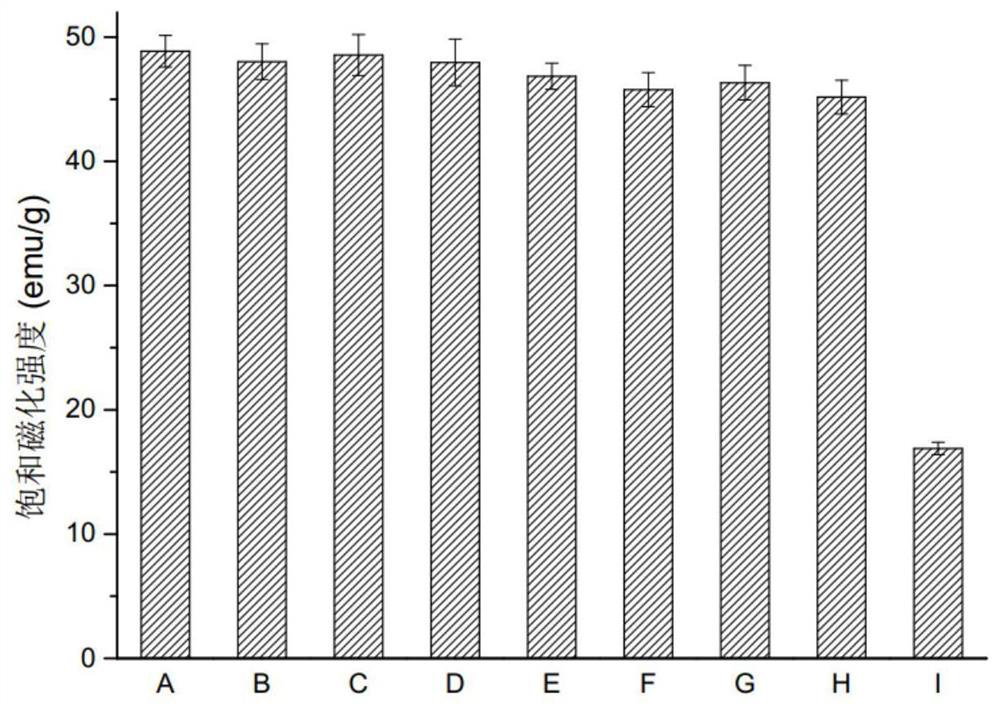

| degree of grafting | aaaaa | aaaaa |

| grafting efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com