Method for regulating and controlling activity of vanadium phosphorus oxide catalyst and application thereof

A vanadium phosphorus oxide, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

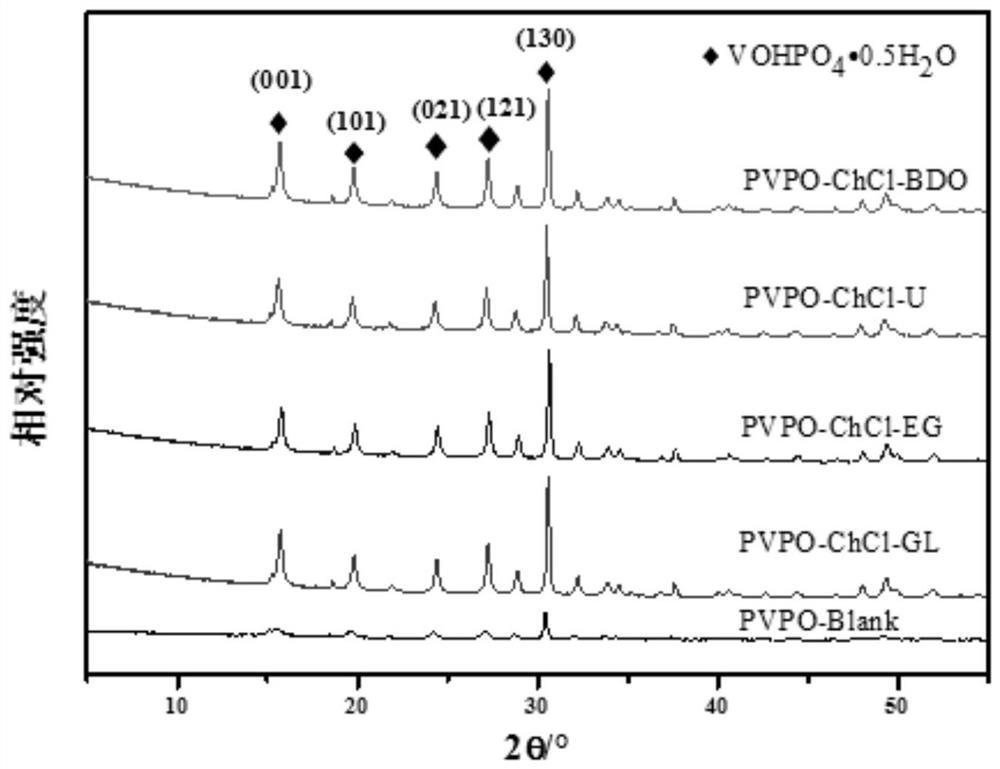

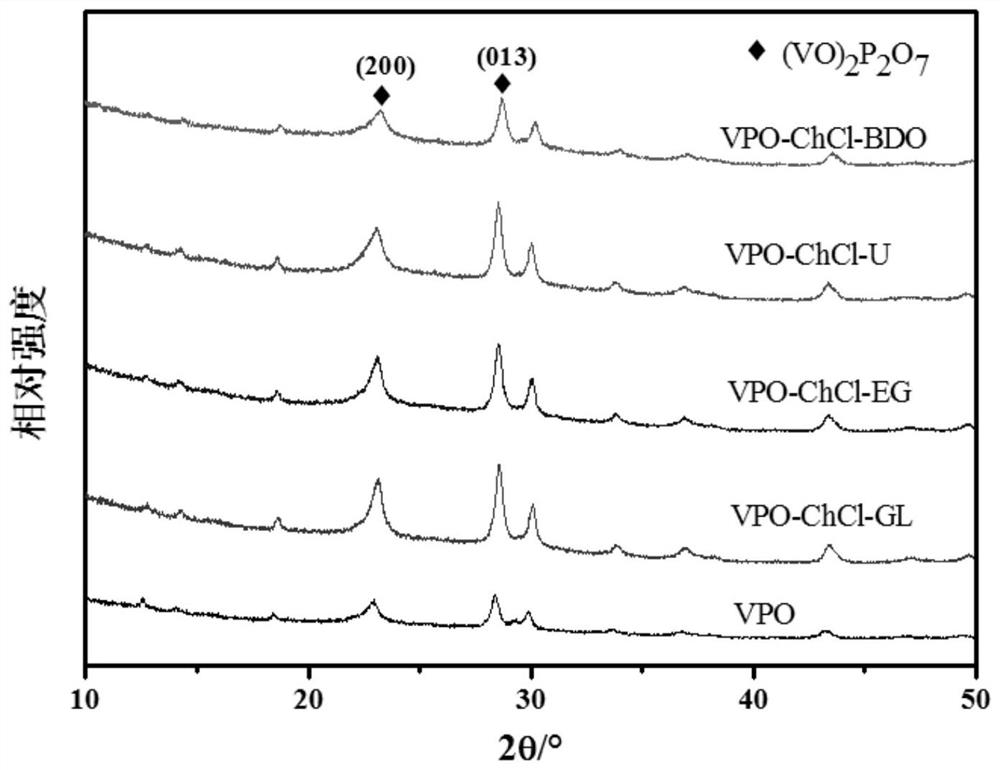

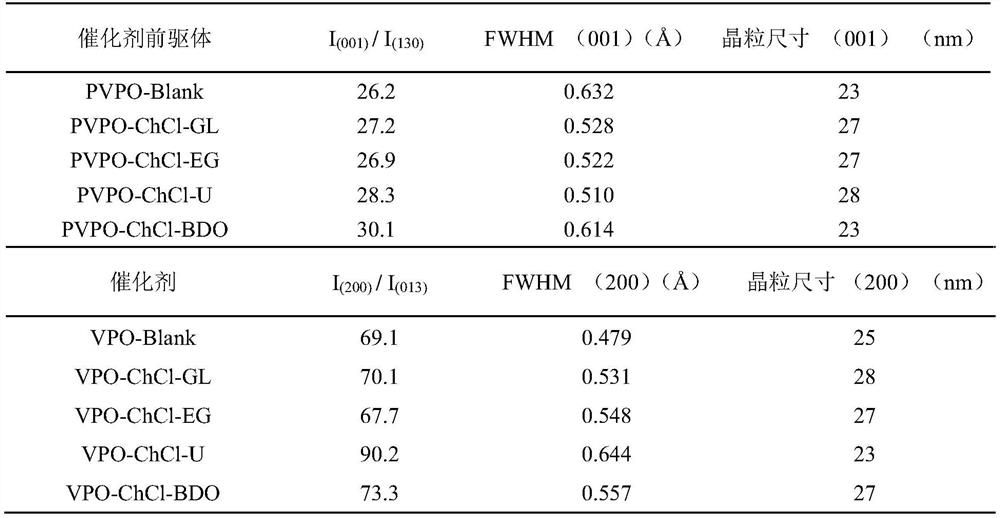

[0025] Preparation of Vanadium Phosphate Precursor

[0026] Weigh 20g V 2 o 5 Mix with benzyl alcohol and isobutanol, raise the temperature to 135°C and heat to reflux for 3 hours under mechanical stirring, then cool down to 75°C, add 16mL of phosphoric acid with a mass fraction of 85wt%, then raise the temperature to 135°C, and heat to reflux under continuous stirring After 16 hours, the product was filtered and dried to obtain a vanadium phosphorus oxide precursor (PVPO-Blank).

[0027] Preparation of deep eutectic solvents

[0028] Choline chloride was mixed with urea at a molar ratio of 1:2, heated to 80°C, and then stirred at 80°C for 3h until a clear solution was obtained and a deep eutectic solvent was obtained.

[0029] In the ball mill tank, mix the vanadium phosphorus oxide precursor with the choline chloride urea deep eutectic solvent according to the mass ratio of 50:1, add the balls according to the ball powder mass ratio of 1:1, then use the ball mill for 6 ho...

Embodiment 2

[0032] Preparation of Vanadium Phosphate Precursor

[0033] Weigh 20g V 2 o 5 Mix with benzyl alcohol and isobutanol, raise the temperature to 135°C and heat to reflux for 3 hours under mechanical stirring, then cool down to 75°C, add 16mL of phosphoric acid with a mass fraction of 85wt%, then raise the temperature to 135°C, and heat to reflux under continuous stirring After 16 hours, the product was filtered and dried to obtain a vanadium phosphorus oxide precursor (PVPO-Blank).

[0034] Preparation of deep eutectic solvents

[0035] Choline chloride was mixed with ethylene glycol at a molar ratio of 1:2, heated to 80°C, and then stirred at 80°C for 3h until a clear solution was obtained and a deep eutectic solvent was obtained.

[0036] In the ball mill tank, mix the vanadium phosphorus oxide precursor with the choline chloride ethylene glycol deep eutectic solvent at a mass ratio of 50:1, add balls at a ball powder mass ratio of 1:1, and then use a ball mill to mill for ...

Embodiment 3

[0039] Preparation of Vanadium Phosphate Precursor

[0040] Weigh 20g V 2 o 5 Mix with benzyl alcohol and isobutanol, raise the temperature to 135°C and heat to reflux for 3 hours under the action of mechanical stirring, then cool down to 75°C, add 16mL of phosphoric acid with a mass fraction of 85wt%, and then raise the temperature to 135°C, under continuous stirring Heating to reflux for 16 hours, filtering the product, and drying to obtain a vanadium phosphorus oxide precursor (PVPO-Blank).

[0041] Preparation of deep eutectic solvents

[0042] Choline chloride was mixed with butanediol at a molar ratio of 1:2, heated to 80°C, and then stirred at 80°C for 3h until a clear solution was obtained and a deep eutectic solvent was obtained.

[0043] In the ball mill tank, mix the vanadium phosphorus oxide precursor with the choline chloride butanediol deep eutectic solvent according to the mass ratio of 50:1, add balls according to the ball powder mass ratio of 1:1, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com