Method for removing free fatty acid in grease by enzyme catalysis

A free fatty acid removal technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of reducing enzyme catalytic activity and stability, increasing the cost of decolorization treatment, loss of active components of oil, etc., to achieve neutral oil loss Small size, good economy and environmental protection, and the effect of improving the oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

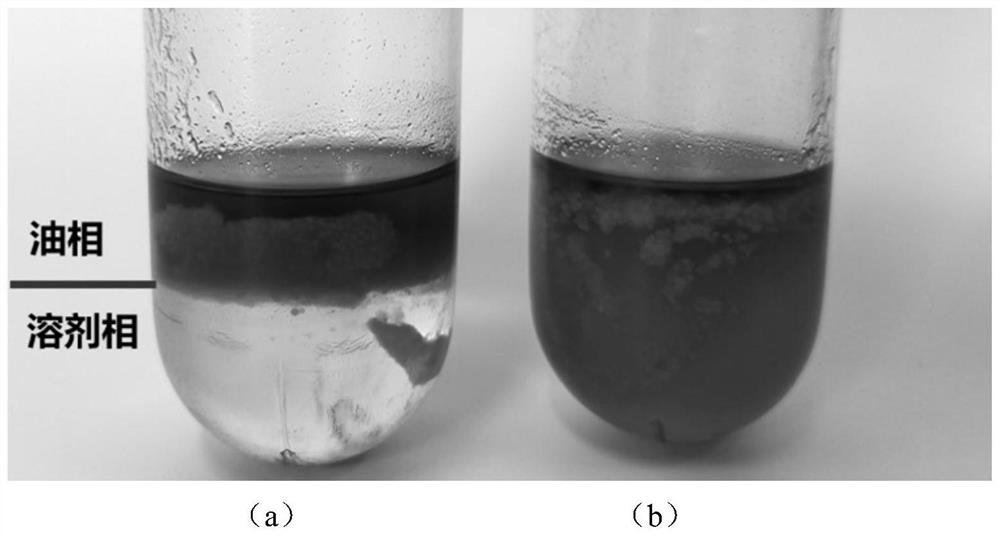

Method used

Image

Examples

Embodiment 1

[0030] Weigh 100 g of choline chloride / glycerol natural deep eutectic solvent with a molar ratio of 1:3 and add it to the reactor, add 100 g of rice bran crude oil, soybean crude oil and rapeseed crude oil to the above prepared Add 10g of Lipozyme TL IM lipase to the solvent, stir the mixture in a water bath at 30°C for 3 hours, centrifuge and take the upper layer of oil for acid value analysis, the acid value of rice bran crude oil is 2.47mg KOH / g, the deacidification rate is 92.78%, and the neutral oil The yield is 97.23%, the measured acid value of soybean crude oil is 0.28mg KOH / g, the deacidification rate is 89.86%, the yield of neutral oil is 98.17%, the measured acid value of rapeseed crude oil is 0.26mg KOH / g, the deacidification rate is 90.91 %, neutral oil yield 96.34%. The deacidification efficiency of the system with continuous recovery of 10 batches of solvent oil and lipase in the lower layer did not decrease significantly.

Embodiment 2

[0032] Weigh 100g of choline chloride / n-butanol natural deep eutectic solvent with a molar ratio of 1:2 and add it to the reactor, and add 50g of rice bran crude oil, soybean crude oil and rapeseed crude oil to the above-mentioned Add 10g Lipozyme RM IM lipase to the prepared solvent, stir the mixture in a water bath at 40°C for 1 hour, centrifuge and take the upper layer of oil for acid value analysis, the acid value of rice bran crude oil is 2.78 mg KOH / g, and the deacidification rate is 91.87%. The yield of neutral oil is 96.27%, the measured acid value of soybean crude oil is 0.27mg KOH / g, the deacidification rate is 90.22%, the yield of neutral oil is 94.23%, the measured acid value of rapeseed crude oil is 0.31mg KOH / g, and the deacidification rate is 90.22%. The yield was 89.16%, and the yield of neutral oil was 80.32%. The deacidification efficiency of the system with continuous recovery of 10 batches of solvent oil and lipase in the lower layer did not decrease signif...

Embodiment 3

[0034] Weigh 100 g of choline chloride / tert-butanol natural deep eutectic solvent with a molar ratio of 1:1 and add it to the reactor, and add 200 g of rice bran crude oil, soybean crude oil and rapeseed crude oil to the above-mentioned Add 10g of Novozyme 435 lipase to the prepared solvent, stir the mixture in a water bath at 50°C for 0.5h, centrifuge and take the upper layer of oil for acid value analysis, the acid value of rice bran crude oil is 4.45mg KOH / g, and the deacidification rate is 86.99%. The yield of neutral oil is 93.16%, the measured acid value of soybean crude oil is 0.24mg KOH / g, the deacidification rate is 91.30%, the yield of neutral oil is 95.31%, the measured acid value of rapeseed crude oil is 0.26mg KOH / g, and the deacidification rate is 91.30%. The yield is 90.91%, and the yield of neutral oil is 95.42%. The deacidification efficiency of the 8-batch system of continuous recovery of lower solvent oil and lipase did not decrease significantly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com