Patterned bacterial cellulose composite membrane with biological activity as well as preparation and application thereof

A technology of bacterial cellulose film and bacterial cellulose, which can be used in viscous dressings, bandages, dressings, etc., and can solve the problems of scar formation and uncontrolled collagen of fibroblasts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Pattern design and preparation of polydimethylsiloxane PDMS template in the present invention, comprise the following steps:

[0051] (1) Use AutoCAD drawing software to design a uniform stripe groove pattern with a width of 10 μm, or a stripe groove pattern with a width of 10 μm and 5 μm alternately arranged. The designed pattern is photolithographically etched on the silicon wafer, and then the surface is silanized by perfluorosilane to enhance the inertia of the surface of the patterned template and prolong the service life;

[0052] (2) Fully mix the two liquids of polydimethylsiloxane (PDMS) and curing agent according to the mass ratio of 10:1, remove the air bubbles, and obtain a transparent viscous liquid; pour the PDMS with the air bubbles removed on the patterned light On the engraving template, the thickness is 3mm, and the air bubbles are further removed by vacuuming;

[0053] (3) Put the template in an oven to completely cure the PDMS, then carefully peel o...

Embodiment 2

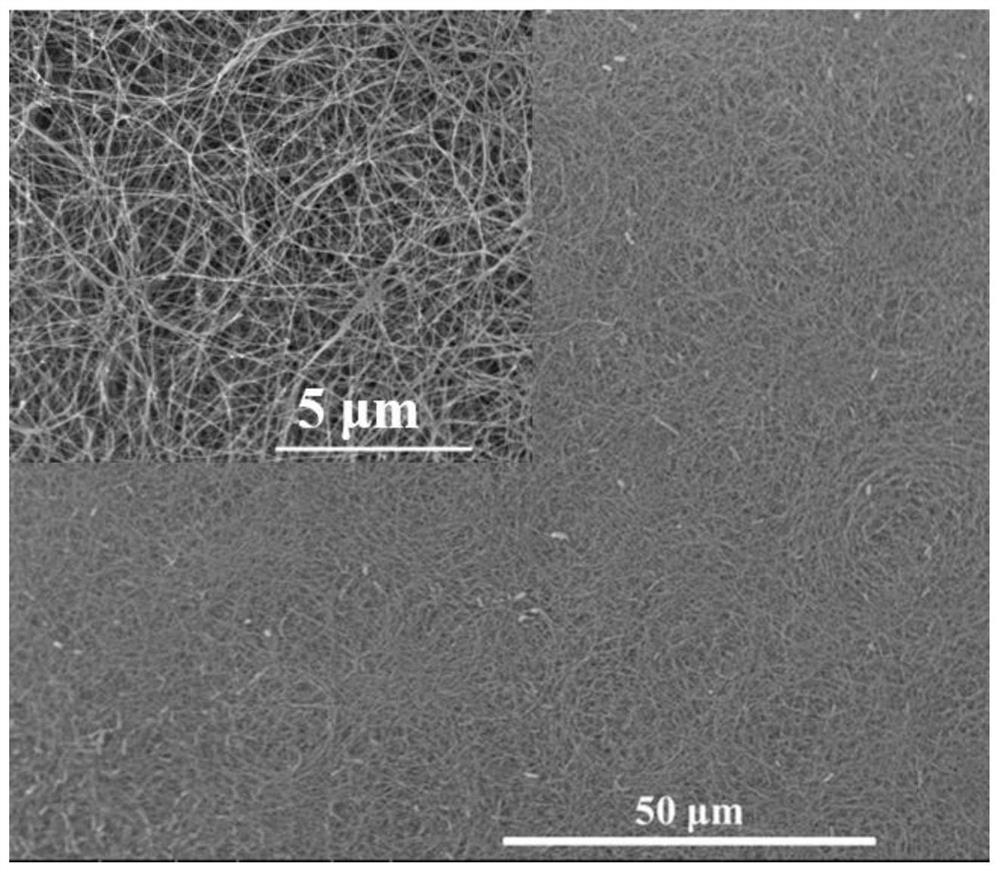

[0056] This embodiment provides a method for preparing a patterned BC membrane, specifically: preparing Hestrin&Schramm medium, and the components and ratios are: citric acid (0.15%, w / v), disodium phosphate (0.27%, w / v), yeast extract (0.5%, w / v), peptone (0.5%, w / v) and glucose (2%, w / v). Dissolve each component in deionized water, inoculate Acetobacter xylinum in the sterilized medium after high temperature sterilization, place the PDMS template with a stripe width of 10 μm upside down in the medium, and incubate at 30°C Cultured for 7 days. Afterwards, boil with 1M NaOH solution to remove residual bacteria in the BC membrane, and then wash with deionized water several times until the pH is neutral. Figure 5 It is the FESEM image of the prepared mBC film, from which it can be seen that the mBC is oriented and arranged as a relatively dense and neatly arranged fiber groove structure.

Embodiment 3

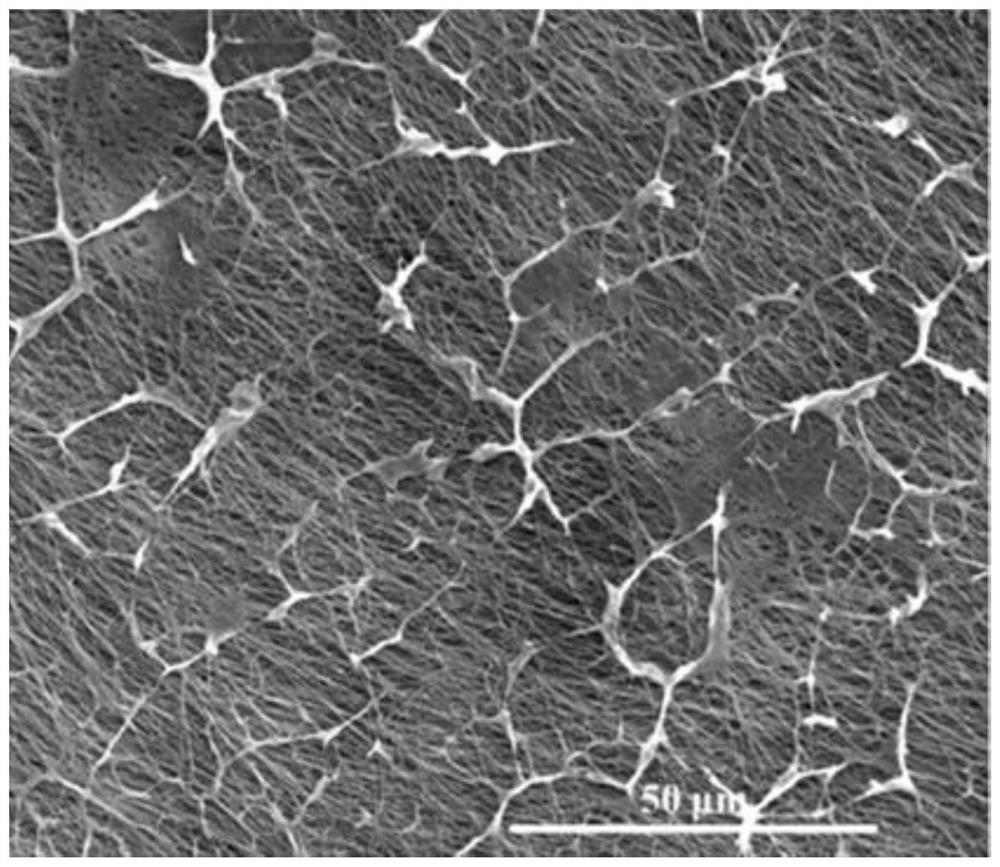

[0058] Prepare Hestrin&Schramm medium, each component and proportion are: citric acid (0.15%, w / v), disodium phosphate (0.27%, w / v), yeast extract (0.5%, w / v), peptone (0.5% , w / v) and glucose (2%, w / v). Each component was dissolved in deionized water, and after high-temperature sterilization, Acetobacter xylinum was inoculated in the sterilized medium, and the striped groove PDMS template with a width of 10 μm and 5 μm was placed upside down in the medium. Cultured in a 30°C incubator for 7 days. Afterwards, boil with 1M NaOH solution to remove the remaining bacteria in the BC film, and then wash it with deionized water for several times until its pH is neutral, and then obtain a film with different widths of staggered fiber groove structures.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com