A kind of koh-modified southeast sedum hydrothermal carbon preparation method and its application

A hydrothermal carbon, modification technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., to achieve the effects of low leaching toxicity, improved efficiency, and stable metal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

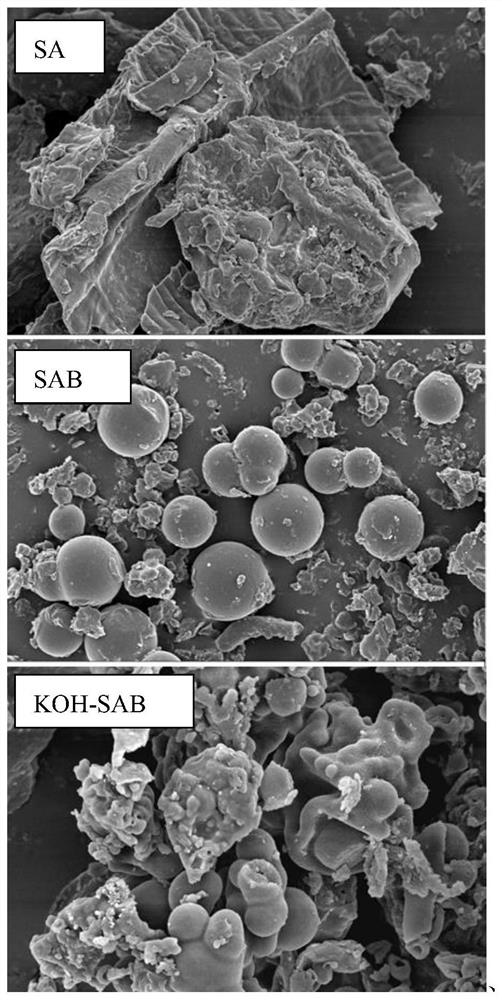

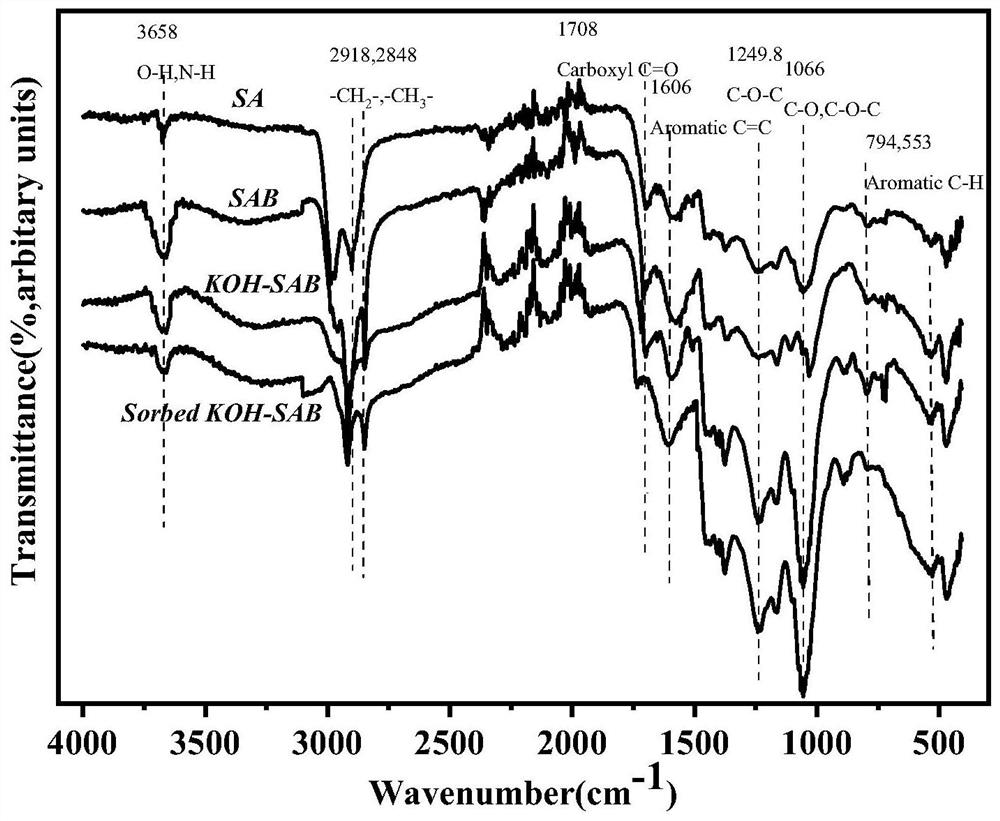

[0052] A method for preparing KOH-modified Southeast Sedum hydrothermal charcoal. The first step is to prepare hydrothermal charcoal with low toxicity. After cleaning the biomass material, the biomass material is dried to constant quality, and the dried biomass is dried. The material is pulverized into powder, mixed with deionized water in a tetrafluoroethylene reactor, put into a muffle furnace, heated at a preset temperature, cooled to room temperature, taken out, ground and sieved to obtain hydrothermal charcoal. The method specifically includes the following steps:

[0053] The plant collected from the lead-zinc mining area was washed with water to remove some dirt and other impurities on it, the roots were cut off, the water on the surface of the plant was dried, and then slightly cut with scissors, and dried in an oven at 60°C To constant weight, then use a plant grinder to pulverize into powder, pulverize the particle size to 1-2mm, seal it and store it in a desiccator ...

Embodiment 2

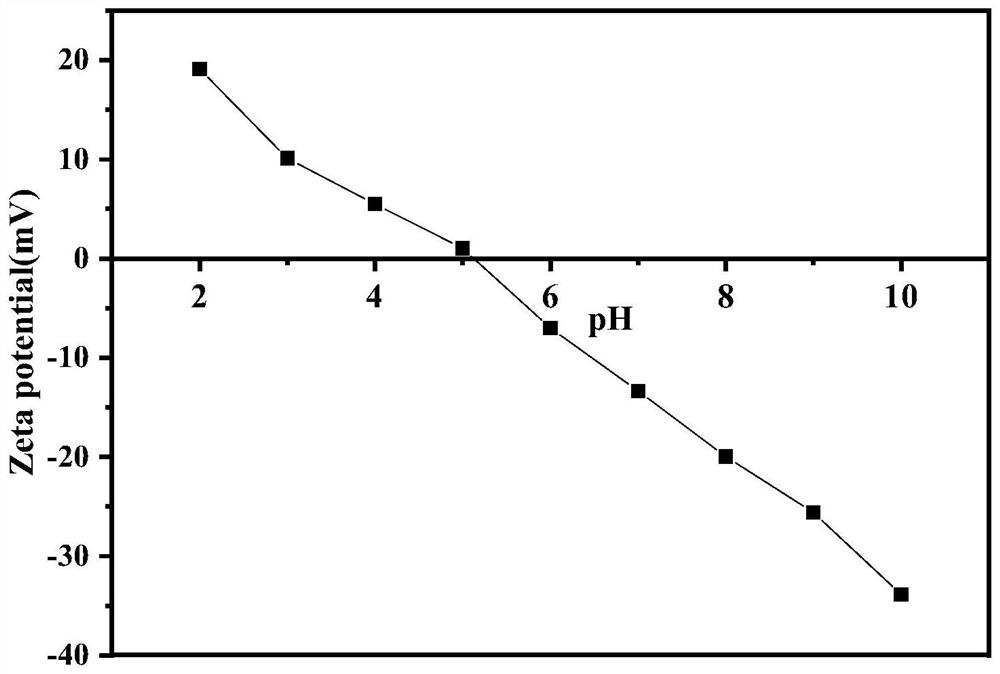

[0103] The difference between this embodiment and the first embodiment is that a KOH-SAB material adsorbs Cd-containing 2+ Application in wastewater, during adsorption, the wastewater is treated to make its pH concentration 6; before wastewater treatment, the Cd in wastewater is treated 2+ The ion concentration was detected according to Cd 2+ The ion concentration to determine the amount of the material added, the amount of the material added per liter of wastewater and the amount of Cd per liter of wastewater 2+ The ratio of the content of ions is 40:1.

Embodiment 3

[0105] The difference between this embodiment and the first embodiment is that a KOH-SAB material adsorbs Cd-containing 2+ Application in wastewater, during adsorption, the wastewater is treated to make its pH concentration 5; before wastewater treatment, the Cd in wastewater is treated 2+ The ion concentration was detected according to Cd 2+ The ion concentration to determine the amount of the material added, the amount of the material added per liter of wastewater and the amount of Cd per liter of wastewater 2+ The ratio of the content of ions is 45:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com