High-temperature-resistant modified polyaspartic acid scale inhibitor as well as preparation method and use method thereof

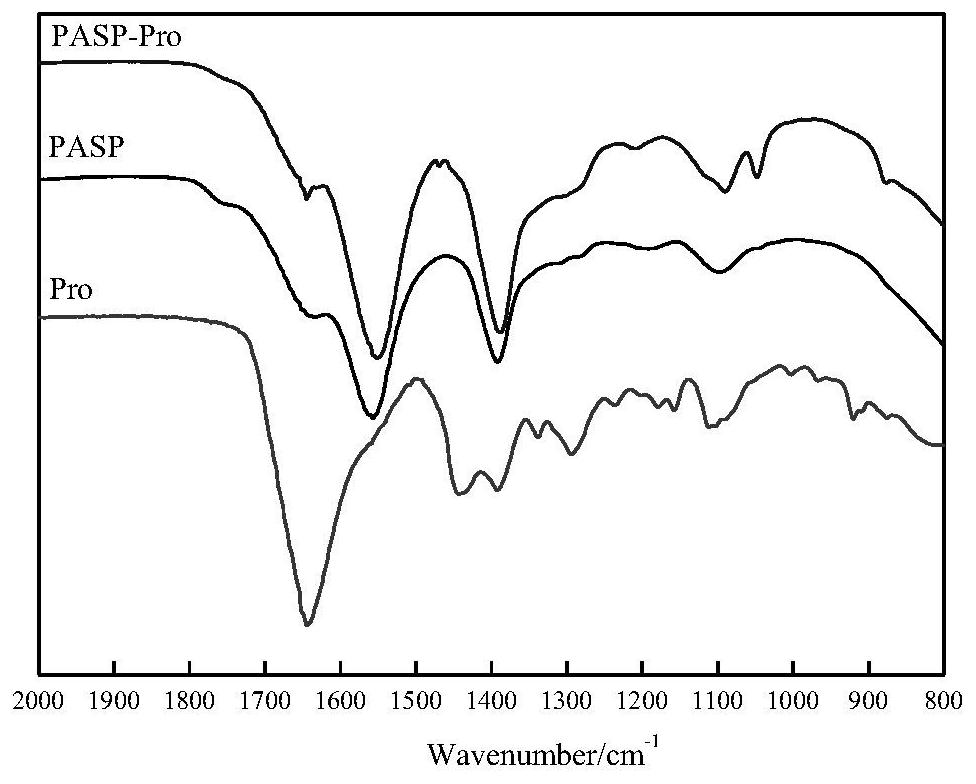

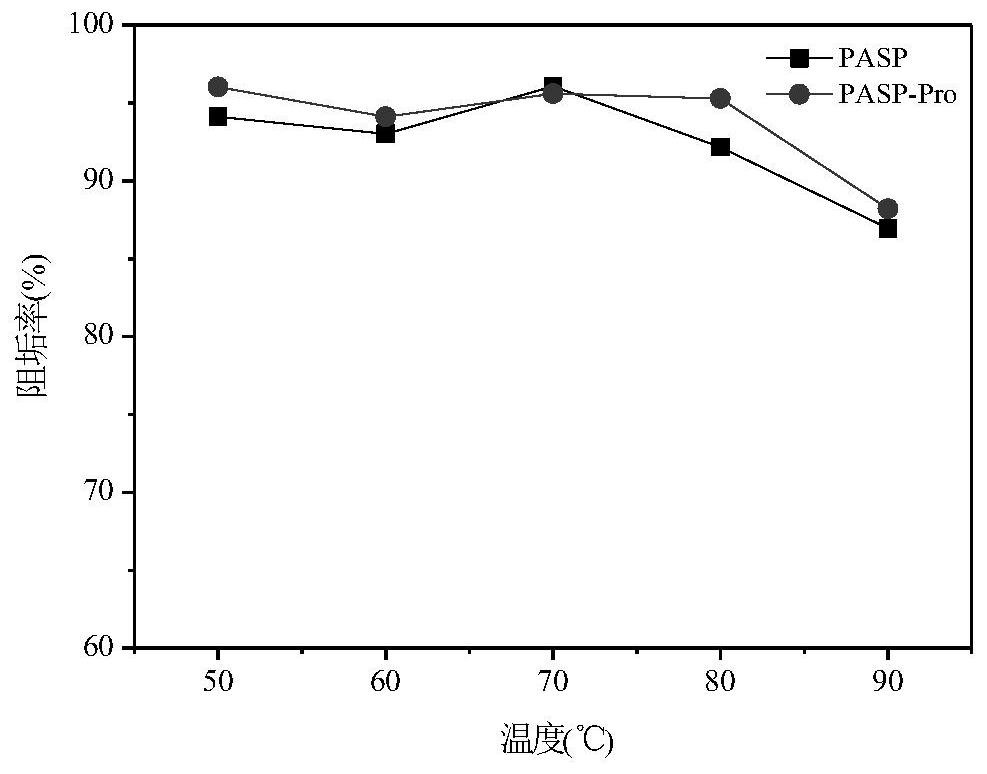

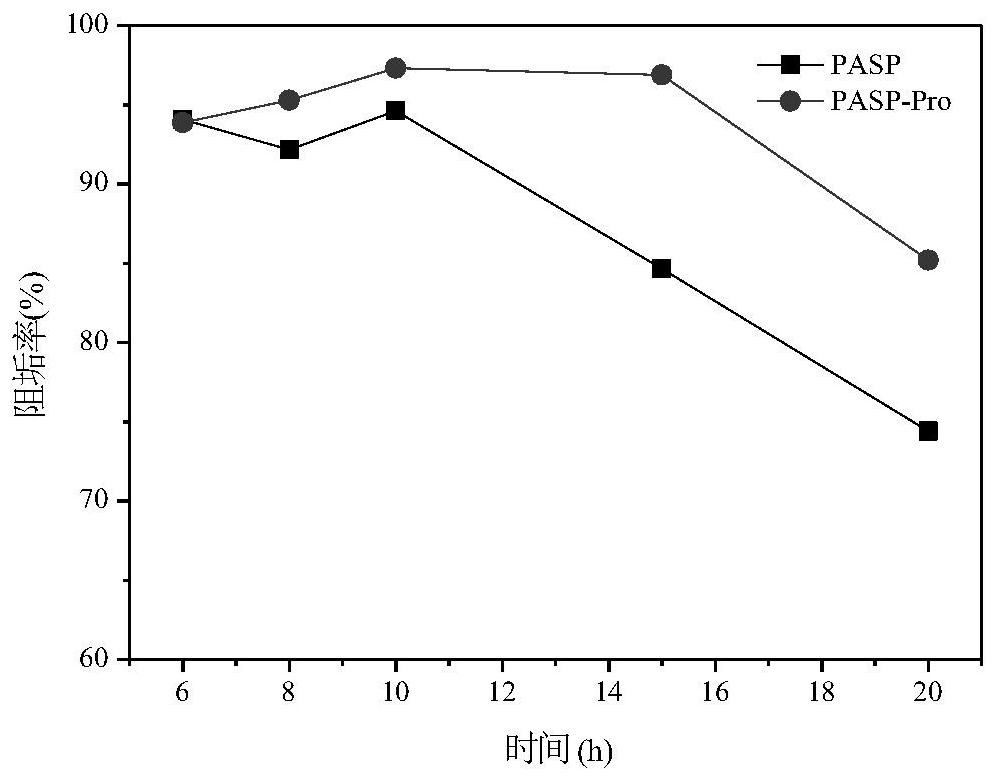

A polyaspartic acid, high temperature resistant technology, used in descaling and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as poor thermal stability, and achieve stable structure and high efficiency Scale inhibitory effect and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The method for preparing a high-temperature-resistant polyaspartic acid scale inhibitor by modifying and modifying a nitrogen-containing heterocyclic small molecule disclosed in the present invention comprises the following steps:

[0047] (A) Preparation of polysuccinimide (PSI) by maleic anhydride method

[0048] Add 20-30g of maleic anhydride solid and 20-30ml of deionized water into a 500ml three-necked flask with a condensing device, then stir magnetically, control the temperature of the oil bath at 80±5°C, and heat for 60-90min to completely dissolve the maleic anhydride .

[0049] Control the molar ratio of maleic anhydride and urea to be 1:0.5~1:0.7, add urea powder evenly to the homogeneous maleic anhydride solution obtained above, control the oil bath temperature to 80±5°C, and heat for 60~90min , so that maleic anhydride and ammonia donor urea fully generate ammonium hydrogen maleate through the ring-opening reaction.

[0050] Put cold water at 5°C into the...

Embodiment 1

[0057] Embodiment 1 (proline amide modified polyaspartic acid)

[0058] Step 1: Add 20g of maleic anhydride and 20ml of distilled water into a 250ml three-necked round-bottomed flask with a condensing device, and stir magnetically in an oil bath at 80°C for 1 hour to dissolve. Slowly add 9 g of urea powder into the solution, and stir magnetically for 1 h until the mixture is uniform. After the experiment started, turn on the condensed water at 5°C, raise the temperature of the oil bath to 160°C, add 2ml of sulfuric acid and phosphoric acid mixed acid with a volume ratio of 1:1, continue to heat up to 180°C, and continue to react for 3 hours, forming on the inner wall of the beaker Orange-red polysuccinimide solid (PSI).

[0059] Step 2: Take out and dry the orange-red polysuccinimide solid obtained in Step 1, add 20ml of N-N-dimethylformamide to dissolve into an orange-red solution, filter, and collect the filtrate with a sufficient amount of absolute ethanol. The pink flocc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com