A high temperature resistant modified polyaspartic acid scale inhibitor and its preparation method and use method

A polyaspartic acid, high temperature resistant technology, used in descaling and water softening, chemical instruments and methods, geothermal power generation, etc., can solve problems such as poor thermal stability, and achieve stable structure, mild synthesis conditions, and reaction. The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

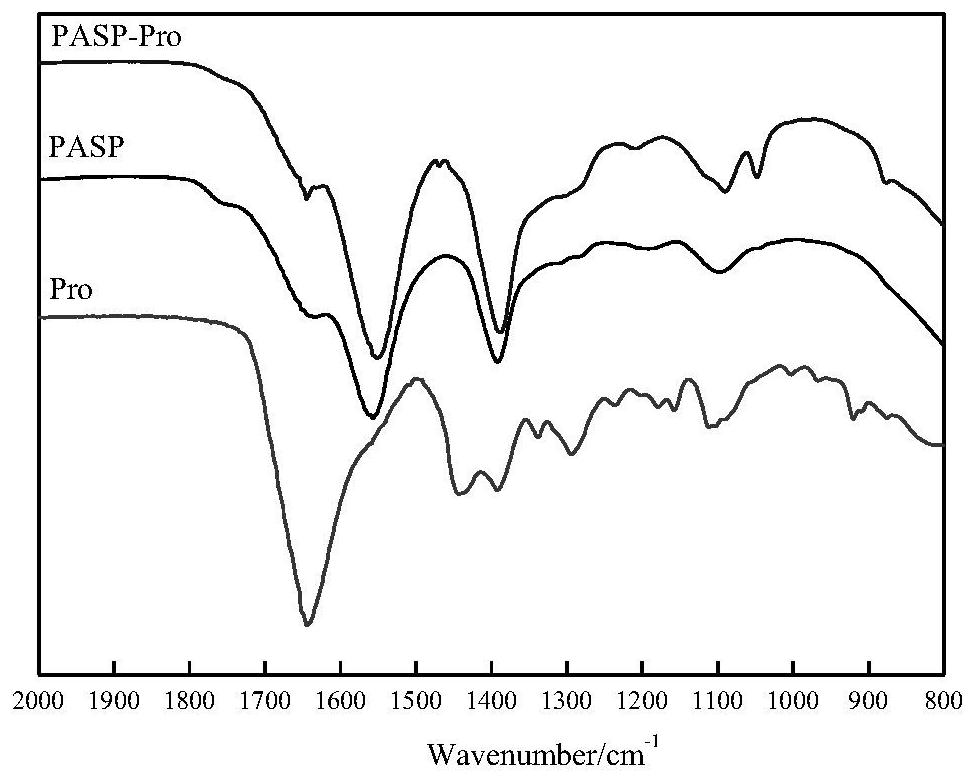

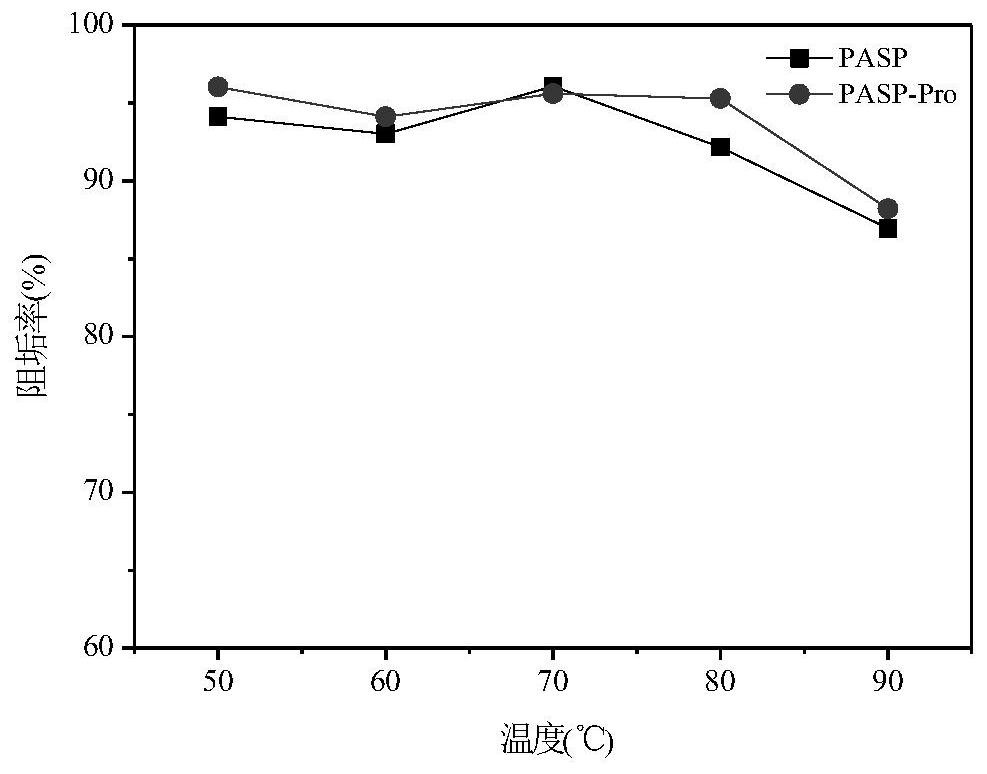

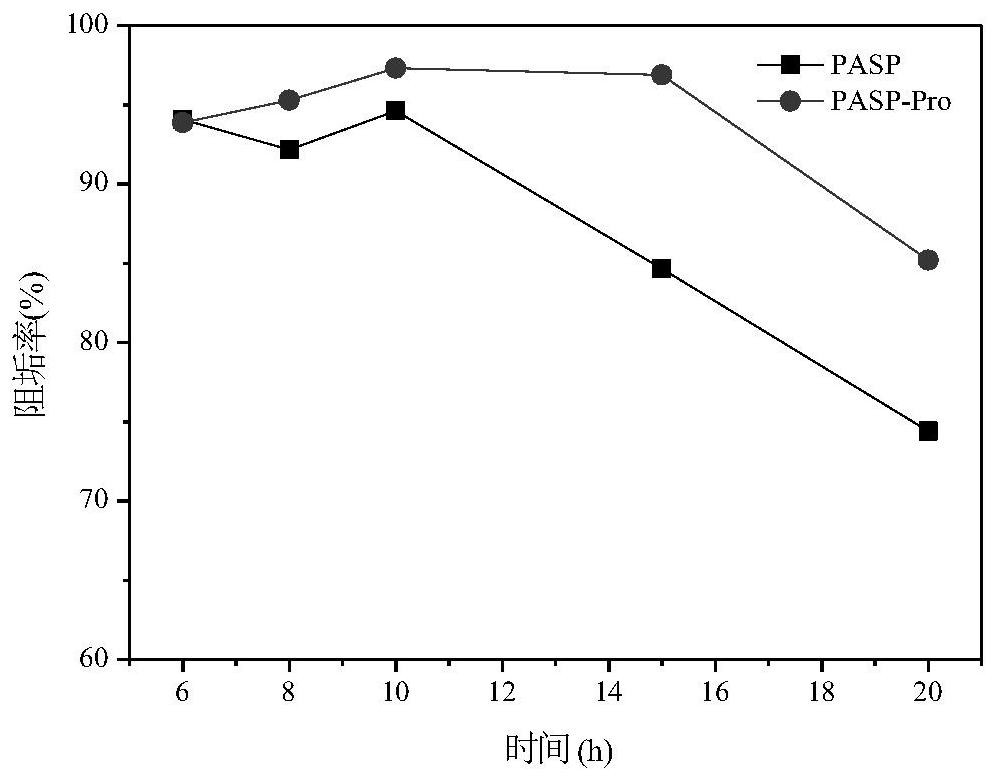

Method used

Image

Examples

preparation example Construction

[0046] The method for preparing a high-temperature-resistant polyaspartic acid scale inhibitor by modifying and modifying a nitrogen-containing heterocyclic small molecule disclosed in the present invention comprises the following steps:

[0047] (A) Preparation of polysuccinimide (PSI) by maleic anhydride method

[0048] Add 20-30g of maleic anhydride solid and 20-30ml of deionized water into a 500ml three-necked flask with a condensing device, then stir magnetically, control the temperature of the oil bath at 80±5°C, and heat for 60-90min to completely dissolve the maleic anhydride .

[0049] Control the molar ratio of maleic anhydride and urea to be 1:0.5~1:0.7, add urea powder evenly to the homogeneous maleic anhydride solution obtained above, control the oil bath temperature to 80±5°C, and heat for 60~90min , so that maleic anhydride and ammonia donor urea fully generate ammonium hydrogen maleate through the ring-opening reaction.

[0050] Put cold water at 5°C into the...

Embodiment 1

[0057] Embodiment 1 (proline amide modified polyaspartic acid)

[0058] Step 1: Add 20g of maleic anhydride and 20ml of distilled water into a 250ml three-necked round-bottomed flask with a condensing device, and stir magnetically in an oil bath at 80°C for 1 hour to dissolve. Slowly add 9 g of urea powder into the solution, and stir magnetically for 1 h until the mixture is uniform. After the experiment started, turn on the condensed water at 5°C, raise the temperature of the oil bath to 160°C, add 2ml of sulfuric acid and phosphoric acid mixed acid with a volume ratio of 1:1, continue to heat up to 180°C, and continue to react for 3 hours, forming on the inner wall of the beaker Orange-red polysuccinimide solid (PSI).

[0059] Step 2: Take out and dry the orange-red polysuccinimide solid obtained in Step 1, add 20ml of N-N-dimethylformamide to dissolve into an orange-red solution, filter, and collect the filtrate with a sufficient amount of absolute ethanol. The pink flocc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com