Olefin isomerization method

A technology of isomerization and isomerization of olefins, applied in the field of isomerization of olefins and skeletal isomerization of post-ether normal olefins. Active olefins and other problems, to achieve the effect of inhibiting polymerization and coking, realizing long-term continuous production, and prolonging the life of a single pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Synthesis of sodium ZSM-35 molecular sieve

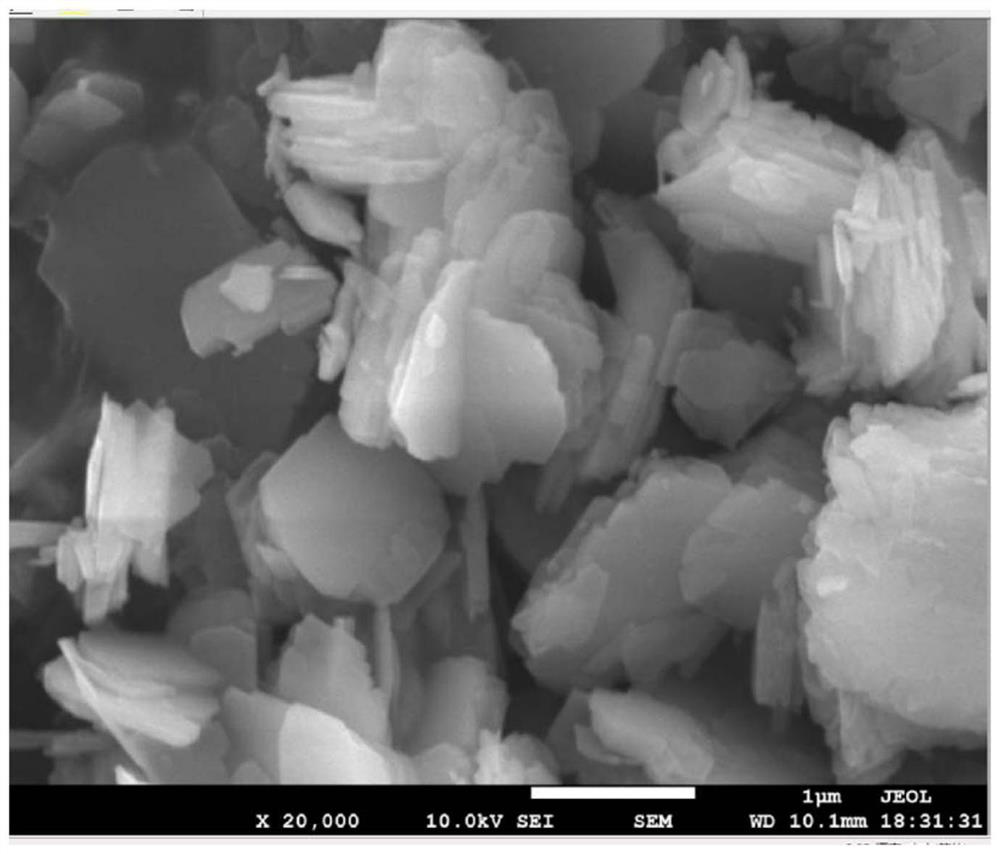

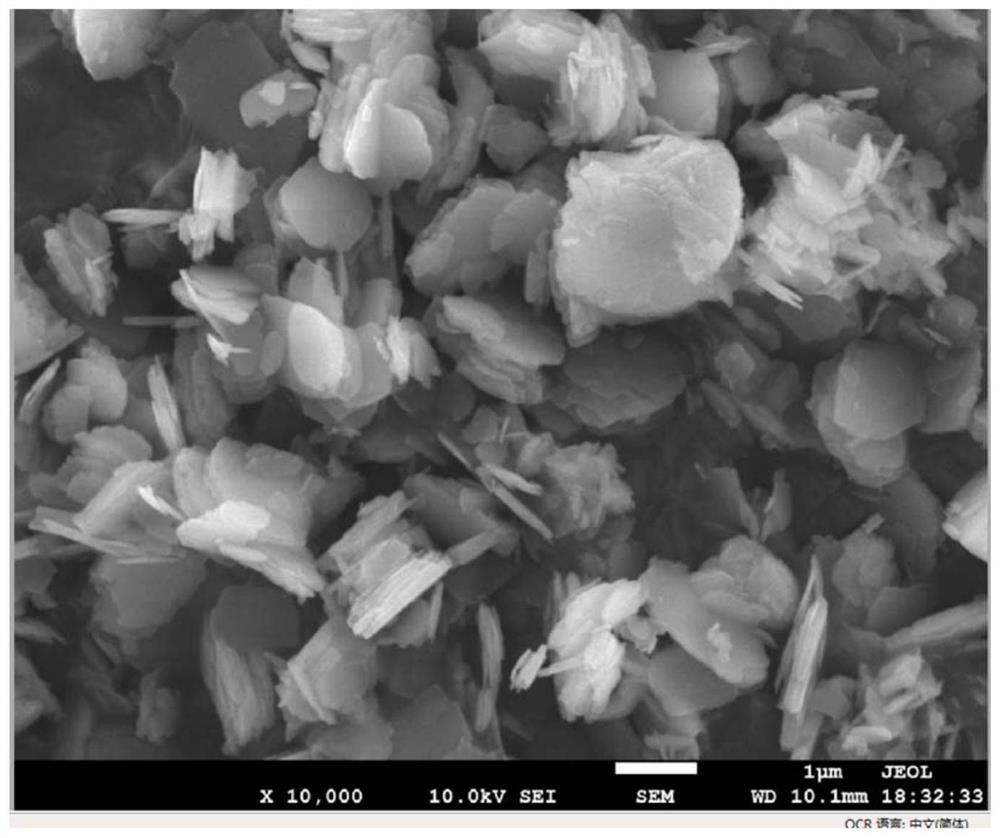

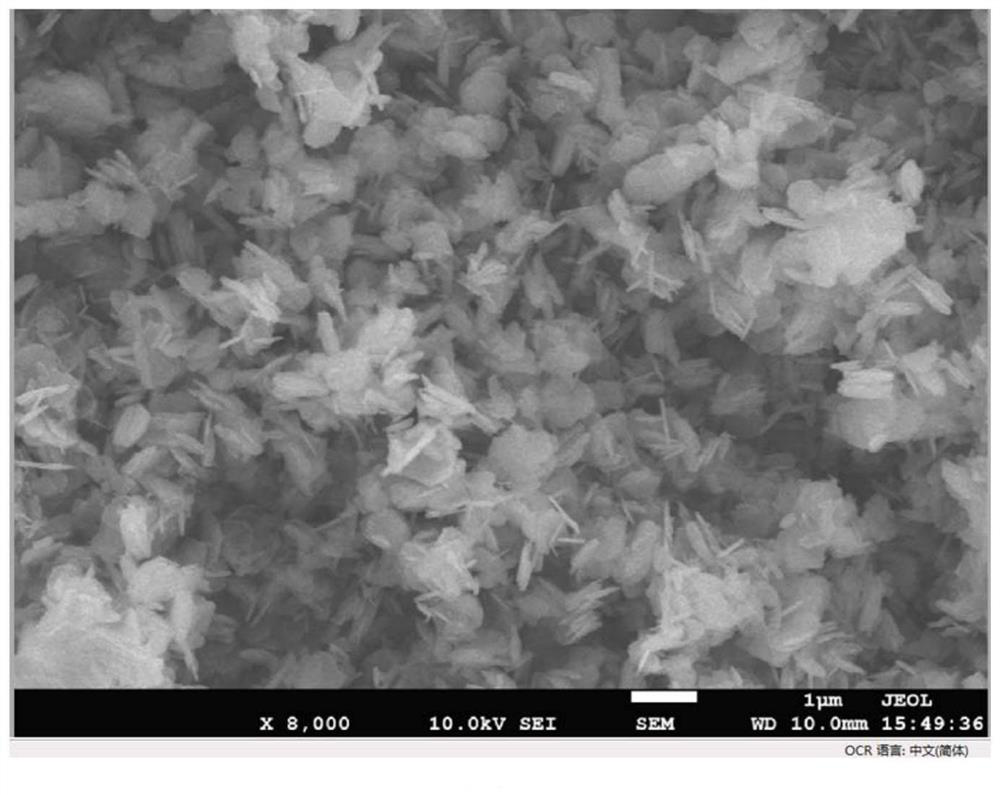

[0048] Using silica sol as the silicon source, aluminum sulfate as the aluminum source, and ethylenediamine as the template, the above-mentioned silicon source, aluminum source, template and concentration are mixed with an aqueous sodium hydroxide solution of 11.2mol / L, and the Al 2 o 3 : SiO 2 : Templating agent: H 2 The ratio of O is 1:29:9:500, and the hydrothermal synthesis reaction is carried out under the conditions of pH value of about 12, temperature of 170°C, and pressure of 0.6MPa. The reaction time is 60 hours. After the reaction, deionized Wash the filtrate with water until neutral, and dry the filter cake to obtain Na-type ZSM-35 molecular sieve with a silicon-aluminum ratio of 25. Observed under the scanning electron microscope, the Na-type ZSM-35 molecular sieve prepared under the above conditions has a nano-sheet structure, such as Figure 1 to Figure 3 shown; the measured specific surface area is 390m ...

Embodiment 2

[0057] 1. Synthesis of sodium ZSM-35 molecular sieve

[0058] Using silica sol as the silicon source, sodium aluminate as the aluminum source, and cyclohexylamine as the template agent, the above-mentioned silicon source, aluminum source, template agent and a concentration of 11.2mol / L sodium hydroxide aqueous solution are mixed, and the Al 2 o 3 : SiO 2 : Templating agent: H 2 The ratio of O is 1:36:12:500, and the hydrothermal synthesis reaction is carried out under the conditions of pH value of about 12, temperature of 160°C, and pressure of 0.6MPa. The reaction time is about 60h. After the reaction, deionized Wash the filtrate with water until neutral, and dry the filter cake to obtain Na-type ZSM-35 molecular sieve, which has a silicon-aluminum ratio of 30.

[0059] 2. Preparation of isomerization catalyst

[0060] Modification of γ-Al with Potassium Nitrate 2 o 3 , using equal volume impregnation, K 2 The O content is 2%, dried at 110°C for 8 hours, and calcined a...

Embodiment 3

[0067] 1. Preparation of isomerization catalyst

[0068] Modification of γ-Al with copper nitrate 2 o 3 , using equal volume impregnation, the content of copper oxide is 2%, drying at 110°C for 8 hours, and roasting at 540°C for 6 hours to obtain a modified catalyst carrier;

[0069] Mix the above-mentioned modified catalyst carrier with the sodium ZSM-35 molecular sieve prepared in Example 1 according to the mass ratio of 20:80, then add 3% aqueous solution of dilute nitric acid, kneading and extrusion molding, and dry at 110°C 8 hours, roasting at 540° C. for 6 hours to obtain a catalyst intermediate;

[0070] Configure 1mol / L NH 4 Cl solution, according to the mass ratio of catalyst intermediate product: ammonium chloride solution being 1: 10, refluxed for 6 hours under 85°C water bath, filtered, dried at about 95°C, and roasted at about 540°C to obtain the isomerization catalyst, record for ISO-UPC-3.

[0071] 3. Olefin isomerization method

[0072] Take 20g of isome...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com