Titanium-doped high-nickel ternary lithium ion battery positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in the field of titanium-doped high-nickel ternary lithium-ion battery positive electrode materials and its preparation, can solve problems such as uneven mixing of raw materials, and achieve stoichiometric ratios that can be accurately controlled and reproducible Good, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

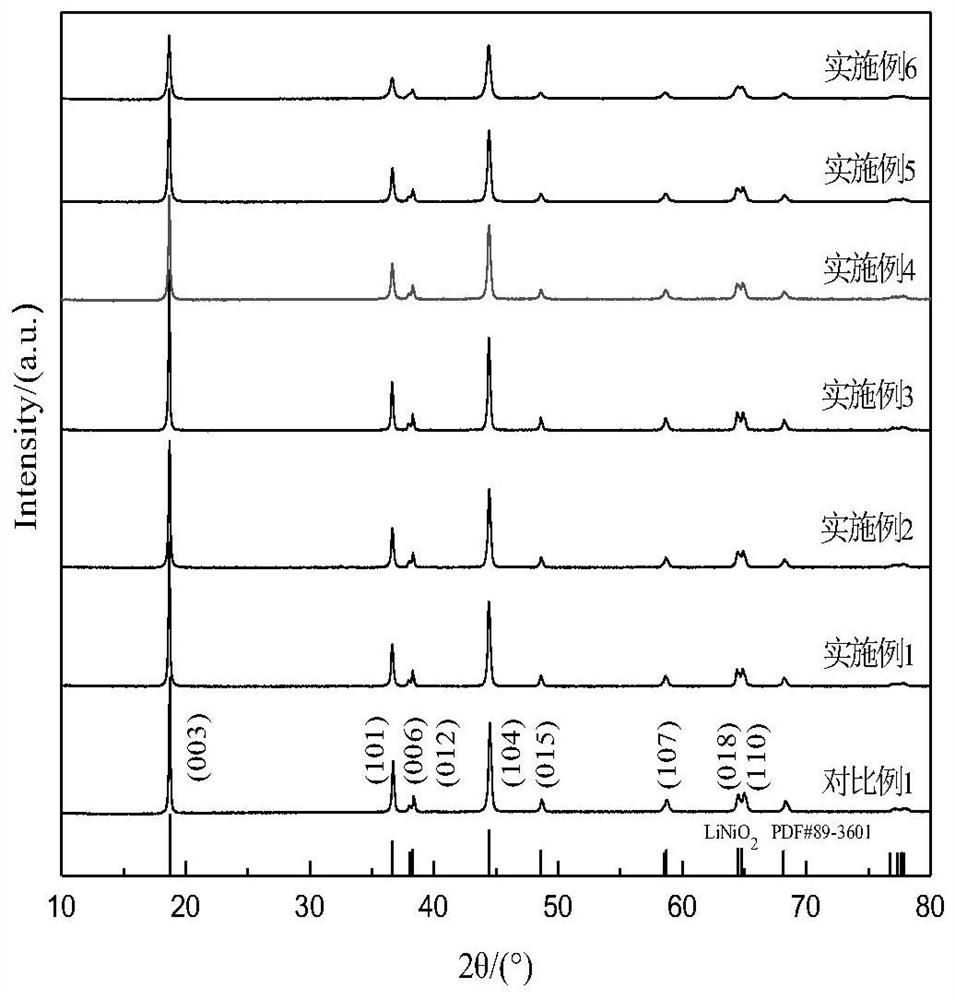

[0029] A preparation method of a titanium-doped high-nickel ternary lithium-ion battery positive electrode material, comprising the steps of: dissolving aluminum salt in absolute ethanol and stirring to obtain solution 1, and then mixing nickel-cobalt binary precursor Ni 0.928 co 0.072 (OH) 2 Add the powder to solution 1 and stir evenly, then add titanium salt, stir evenly to obtain slurry 1; prepare solution 2, the volume ratio of deionized water and absolute ethanol in solution 2 is 1:2, add solution 2 to slurry 1, and stir Obtain the mixed slurry 2 uniformly, heat the mixed slurry 2 to 50°C-70°C and stir for 1-2h, age at room temperature, filter, and dry to obtain the ternary precursor; take the ternary precursor and LiOH·H 2 O is evenly mixed, where n(Li):n(Ni+Co+Al)=1.05:1, and is calcined in stages in an atmosphere furnace filled with oxygen, first at 450°C-550°C for 3.5-4.5h, then at 600°C Insulate at -800°C for 12-15 hours, and finally cool down to room temperature w...

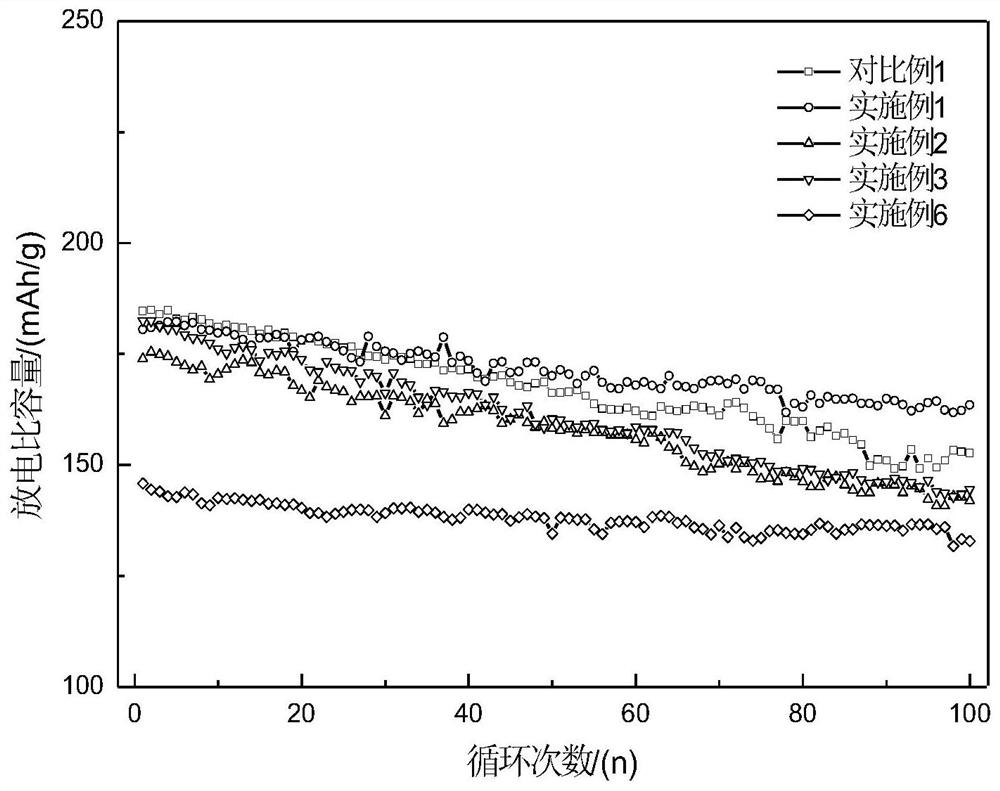

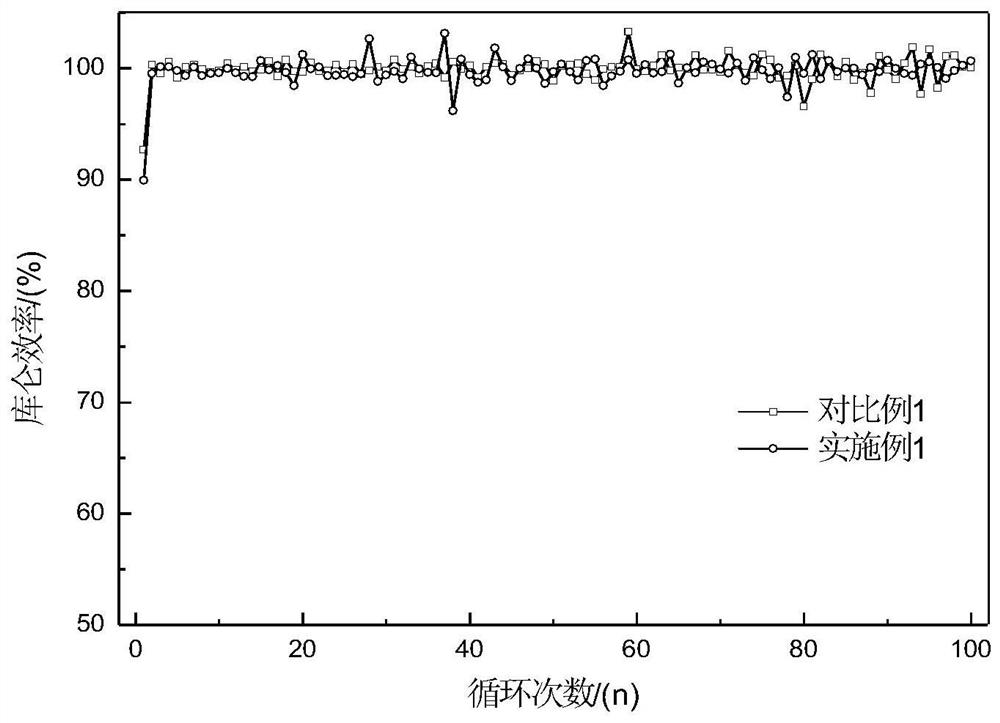

Embodiment 1

[0037] Weighed 4.26g of aluminum isopropoxide (purity 99.99%), dissolved in 50mL of absolute ethanol, and stirred for 1.5h with a magnetic stirrer at room temperature at 1300 rpm to obtain solution 1. Then weigh 36.43g Ni 0.928 co 0.072 (OH) 2 Powder, add solution 1 and magnetically stir for 0.25h, then add titanium isopropoxide 1.88mL, continue magnetically stirring for 0.25h to obtain slurry 1. Prepare 60 mL of solution 2, wherein the volume ratio of deionized water and absolute ethanol in solution 2 is 1:2. Add solution 2 to slurry 1, continue magnetic stirring for 0.5h to obtain mixed slurry 2, heat up mixed slurry 2 to 60°C, stir at 1000rpm for 1.5h, age at room temperature for 24h, filter, and dry in a drying oven at 80°C Dry for 24 hours to obtain dry powder (ternary precursor). Take dry powder 18.98g and 9.18gLiOH·H 2 O mixed evenly, where n(Li):n(Ni+Co+Al)=1.05:1, calcined in stages in an atmosphere furnace filled with oxygen, first at 500°C for 4h, then at 700°C...

Embodiment 2

[0039] Weighed 4.26g of aluminum isopropoxide (purity 99.99%), dissolved in 50mL of absolute ethanol, and stirred for 1.5h with a magnetic stirrer at room temperature at 1300 rpm to obtain solution 1. Then weigh 36.43g Ni 0.928 co 0.072 (OH) 2 Powder, add solution 1 and magnetically stir for 0.25h, then add 0.63mL of titanium isopropoxide, continue magnetically stirring for 0.25h to obtain slurry 1. Prepare 60 mL of solution 2, in which the volume ratio of deionized water and absolute ethanol is 1:2. Solution 2 was added to slurry 1, and magnetic stirring was continued for 0.5 h to obtain mixed slurry 2. Raise the temperature to 60°C, stir at 1000rpm for 1.5h, age at room temperature for 24h, filter, and dry in a drying oven at 80°C for 24h to obtain dry powder (ternary precursor). Take dry powder 19.10g and 9.18gLiOH·H 2 O is evenly mixed, where n(Li):n(Ni+Co+Al)=1.05:1, and is calcined in stages in an atmosphere furnace filled with oxygen, first at 500°C for 4h, then at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com