Magnetic core-shell structure carbon material, preparation method thereof and application of magnetic core-shell structure carbon material in desulfurization

A core-shell structure, carbon material technology, applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., can solve problems such as limiting performance, inefficient adsorption of thiophene sulfides, hindering large-scale applications, etc. High desulfurization efficiency, best desulfurization efficiency, enhanced adsorption capacity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

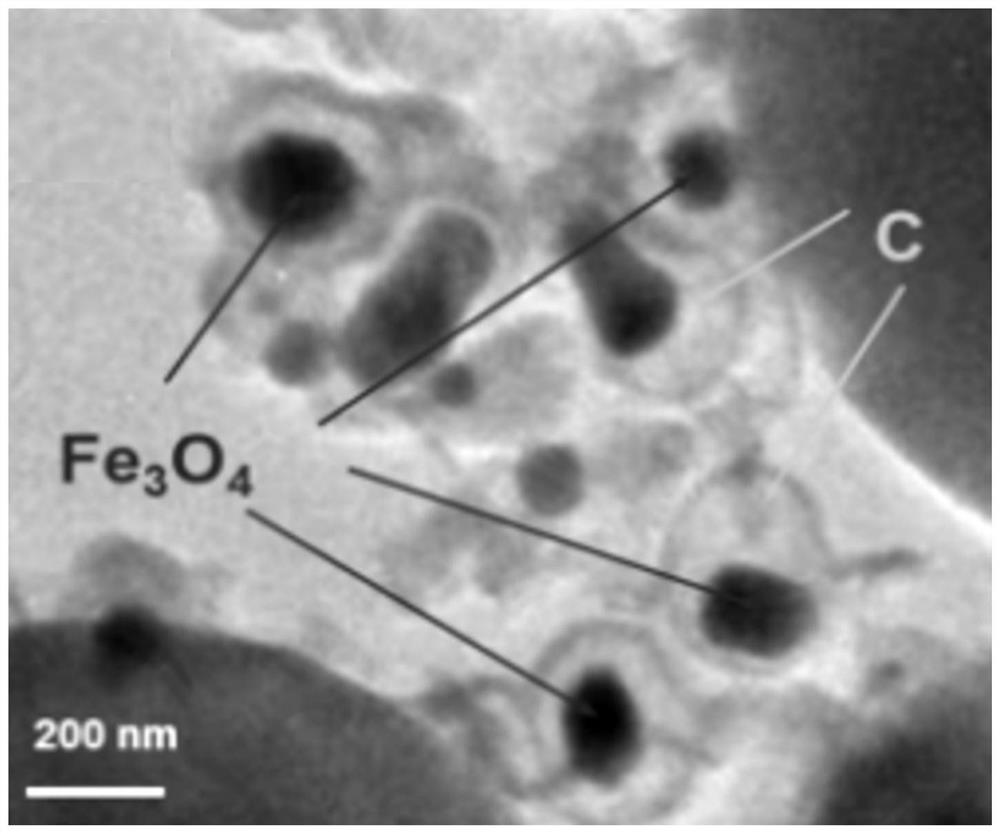

[0045] This implementation provides a method for preparing a magnetic core-shell structure carbon material, comprising the following steps:

[0046] Step 1: 0.5g of FeCl 3 ·6H 2 O and 1.0 g of urea were dissolved in 35 mL of ethylene glycol; then transferred to a 50 mL stainless steel autoclave (reaction pressure 0.06 MPa) and heated at 200 °C for 6 h; after cooling to room temperature, the resulting solid was collected with a magnet The product was washed sequentially with distilled water and ethanol to obtain the final Fe 3 o 4 The product was dried under vacuum for further use.

[0047] Step 2: Add 120mg of Fe 3 o 4The product was dispersed in 30mL, 0.6mol / L glucose solution, and put into a 50mL Teflon-lined stainless steel autoclave (reaction pressure 0.06MPa), and the reactor was placed in an oven preheated to 180°C for 6h; The solid product was collected, washed with distilled water and ethanol, and dried overnight at 120 °C.

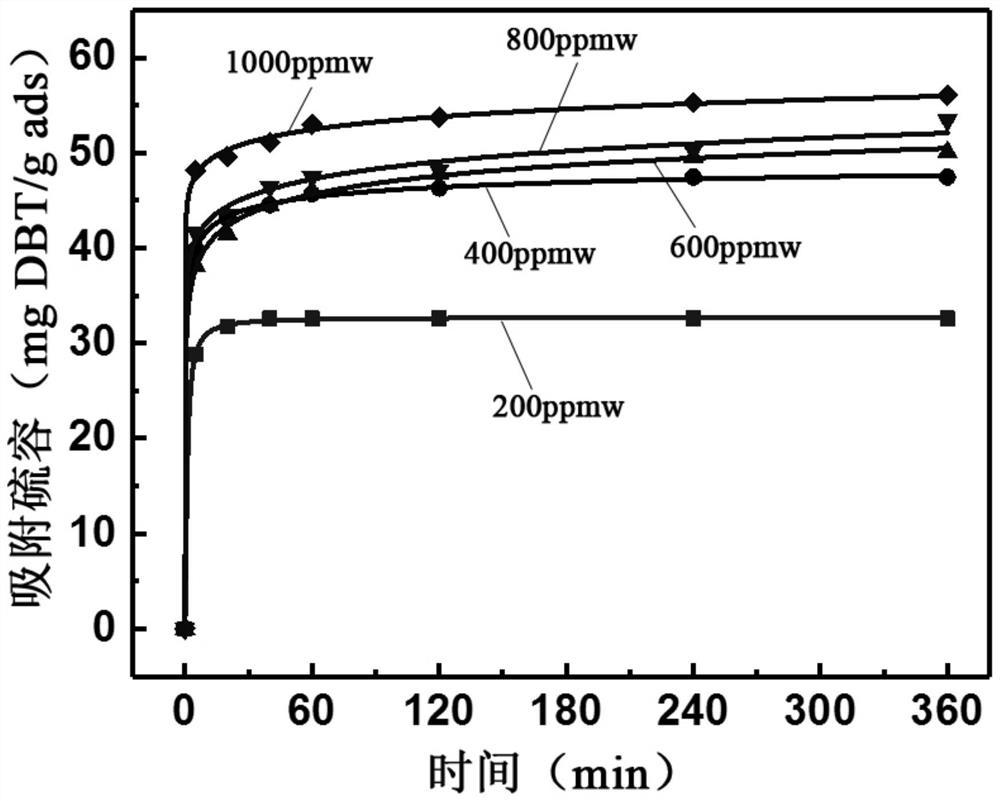

[0048] Step 3: In the furnace tube, ...

Embodiment 2

[0054] This implementation provides a method for preparing a magnetic core-shell structure carbon material, comprising the following steps:

[0055] Step 1: 0.5g of FeCl 3 ·6H 2 O and 1.0 g of urea were dissolved in 35 mL of ethylene glycol; then transferred to a 50 mL stainless steel autoclave (reaction pressure 0.06 MPa) and heated at 200 °C for 9 h, after cooling to room temperature, the resulting solid was collected with a magnet The product was washed sequentially with distilled water and ethanol to obtain the final Fe 3 o 4 The product was dried under vacuum for further use.

[0056] Step 2: Add 120mg of Fe 3 o 4 The product was dispersed in 30mL, 0.6mol / L glucose solution, and filled into a 50mL Teflon-lined stainless steel autoclave (reaction pressure 0.06MPa), and the reactor was placed in an oven preheated to 180°C for 9h; The solid product was collected, washed with distilled water and ethanol, and dried overnight at 120 °C.

[0057] Step 3: In the furnace tu...

Embodiment 3

[0062] This implementation provides a method for preparing a magnetic core-shell structure carbon material, comprising the following steps:

[0063] Step 1: 0.5g of FeCl 3 ·6H 2 O and 1.0 g of urea were dissolved in 35 mL of ethylene glycol; then transferred to a 50 mL stainless steel autoclave (reaction pressure 0.06 MPa) and heated at 200 °C for 12 h; after cooling to room temperature, the resulting solid was collected with a magnet The product was washed sequentially with distilled water and ethanol to obtain the final Fe 3 o 4 The product was dried under vacuum for further use.

[0064] Step 2: Add 120mg of Fe 3 o 4 The product was dispersed in 30mL, 0.6mol / L glucose solution, and put into a 50mL Teflon-lined stainless steel autoclave (reaction pressure 0.06MPa). The solid product was collected, washed with distilled water and ethanol, and dried overnight at 120 °C.

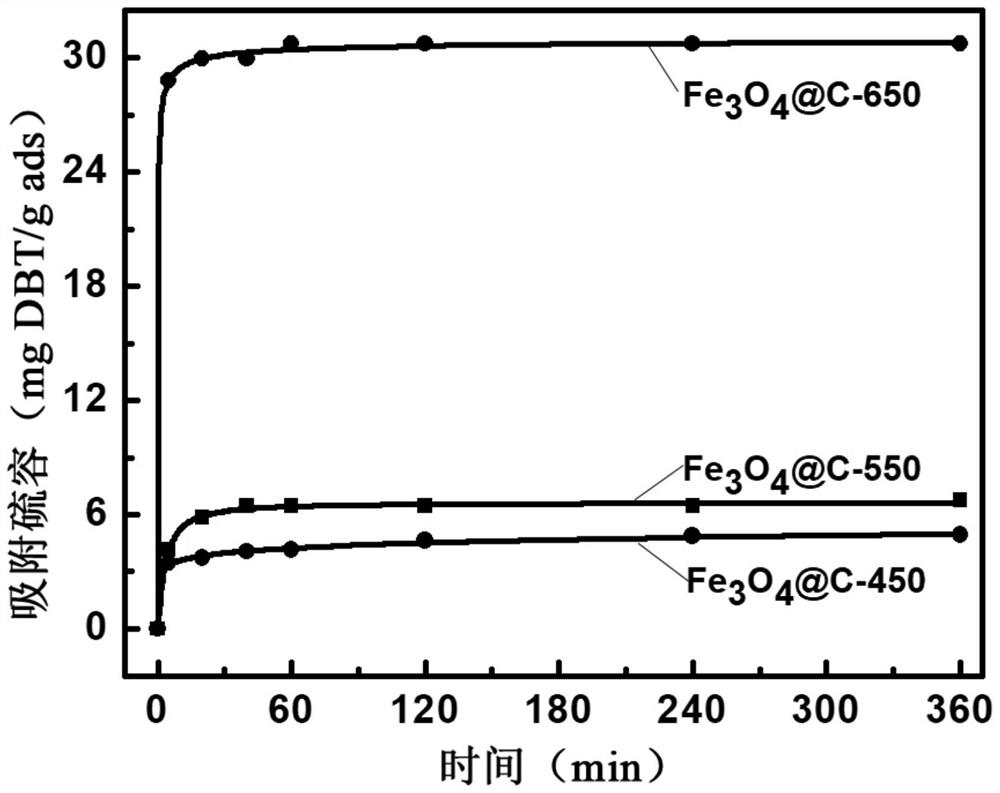

[0065] Step 3: In the furnace tube, heat the solid product obtained in Step 2 to 450°C under a nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com