Preparation method of graphene-loaded nanosheet transition metal hydride and hydrogen storage material

A technology of transition metals and nanosheets, applied in the direction of transition element hydrides, chemical instruments and methods, non-metallic elements, etc., can solve problems such as high kinetic energy barrier, low hydrogen storage capacity, and difficulty in reversible hydrogen absorption, and achieve It is beneficial to the improvement of capacity, fine particle size, hydrogen desorption kinetics and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of graphene-supported nanosheet titanium hydride catalyst:

[0047] (1) Titanium tetrachloride (2mmol), lithium hydride (8mmol), graphene (20mg) and tetrahydrofuran (50ml) were weighed in an argon atmosphere glove box, added to a stainless steel reaction vessel, and sealed.

[0048] (2) Transfer the airtight stainless steel reaction vessel to a magnetic heating stirrer, and keep it at 100°C for 2h or at 100°C for 4h or at 200°C for 2h.

[0049] (3) In an inert atmosphere glove box, the product in step (2) is filtered under reduced pressure to obtain a solid powder.

[0050] (4) Heating the solid powder obtained in step (3) to 70° C. for 6 hours under dynamic vacuum to remove residual tetrahydrofuran, and finally obtain a graphene-supported nanosheet-shaped titanium hydride catalyst.

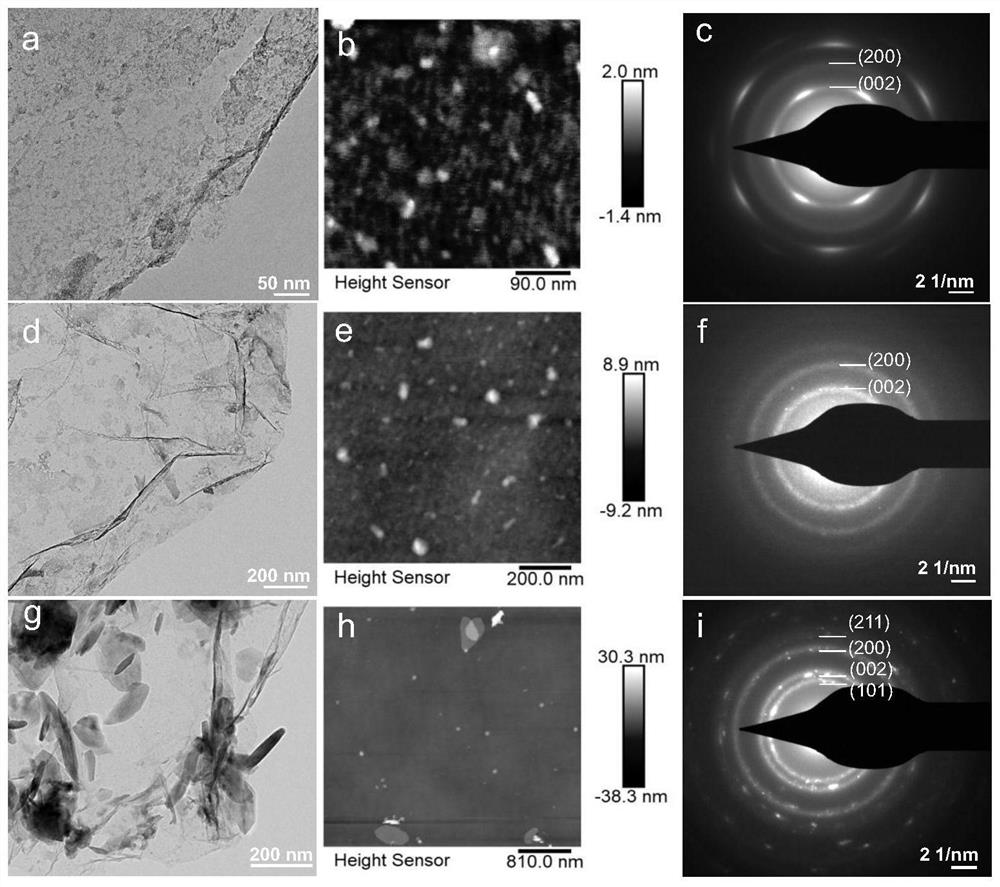

[0051] The sample prepared in the above process is: graphene-supported nanosheet titanium hydride catalyst (NF-TiH 2 @G). figure 1 a is the transmission electron microscope ...

Embodiment 2

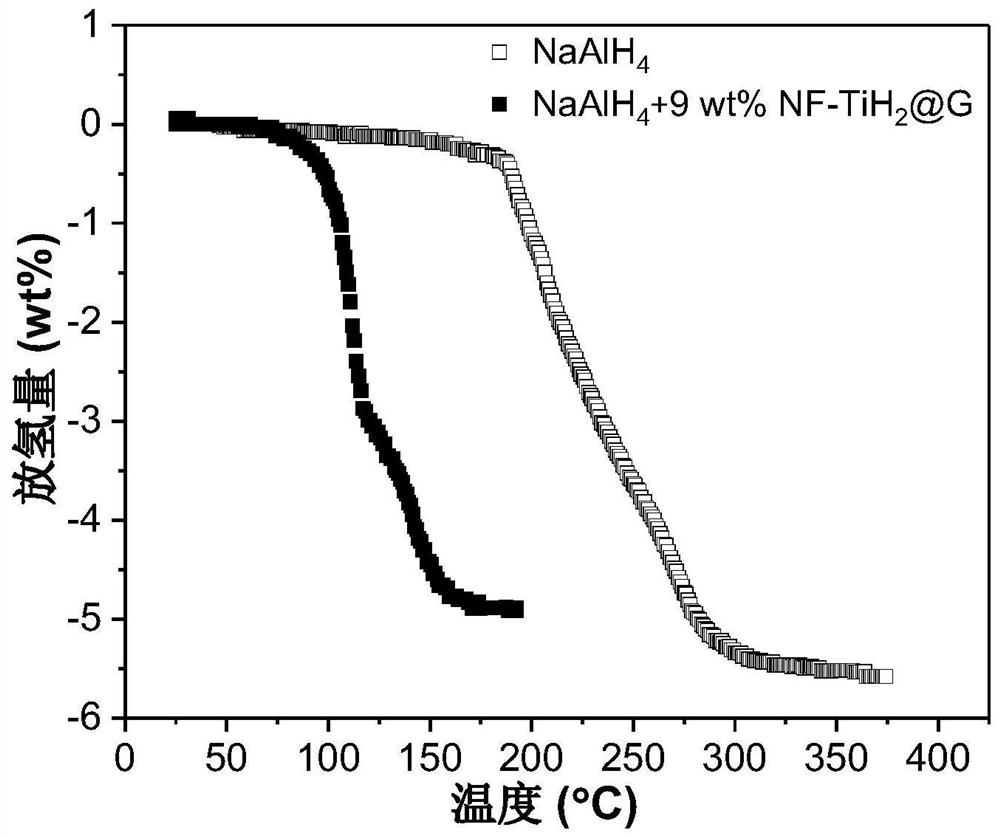

[0055] Add NF-TiH 2 @G NaAlH 4 Preparation of hydrogen storage material: NF-TiH with Example 1 (step 2 adopts 100°C for 2h) 2 @G as catalyst with NaAlH 4 As a hydrogen storage material, NF-TiH was weighed separately in an argon atmosphere glove box 2 @G and NaAlH 4 , added to the ball mill jar, sealed, where NF-TiH 2 The mass fraction of @G in the mixture is 9wt%. Transfer the ball mill tank to a ball mill for ball milling, the ball milling speed is 500 rpm, the ball-to-material ratio is 120:1, and the ball milling time is 24 hours, to obtain the hydrogen storage material NaAlH 4 +9wt%NF-TiH 2 @G. The hydrogen desorption kinetics of the hydrogen storage material was tested by the volumetric method, and the test condition was under vacuum (the initial vacuum degree was 1×10 -3 Torr) heated to 250°C at a heating rate of 2°C / min, the results are shown in figure 2 .

Embodiment 3

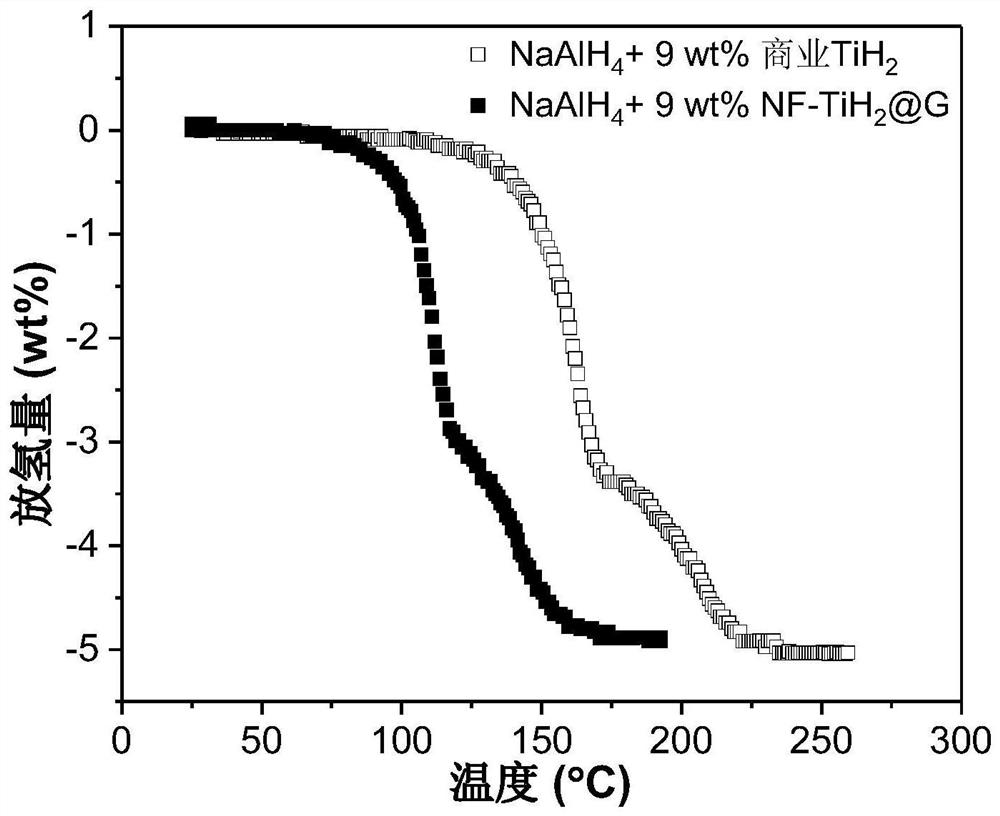

[0063] Add NF-TiH 2 @G NaAlH 4 Preparation of hydrogen storage material: NF-TiH with Example 1 (step 2 adopts 100°C for 2h) 2 @G as catalyst with NaAlH 4 As a hydrogen storage material, NF-TiH was weighed separately in an argon atmosphere glove box 2 @G and NaAlH 4 , added to the ball mill jar, sealed, where NF-TiH 2The mass fraction of @G in the mixture is 9wt%. Transfer the ball mill tank to a ball mill for ball milling, the ball milling speed is 500 rpm, the ball-to-material ratio is 120:1, and the ball milling time is 24 hours, to obtain the hydrogen storage material NaAlH 4 +9wt%NF-TiH 2 @G. TPD (temperature dependent hydrogen desorption) was used to test the hydrogen desorption kinetics of the hydrogen storage material. The test condition was to heat up to 250°C at a heating rate of 2°C / min under an argon carrier gas. The results are shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com